Assembled integral shear wall structure system and construction method thereof

A shear wall and integral technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of complex on-site construction procedures and management, hindering the application of prefabricated large-slab buildings, and affecting the lives and work of surrounding residents , to achieve the effect of saving the decoration period, simplifying the construction process and consistent specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

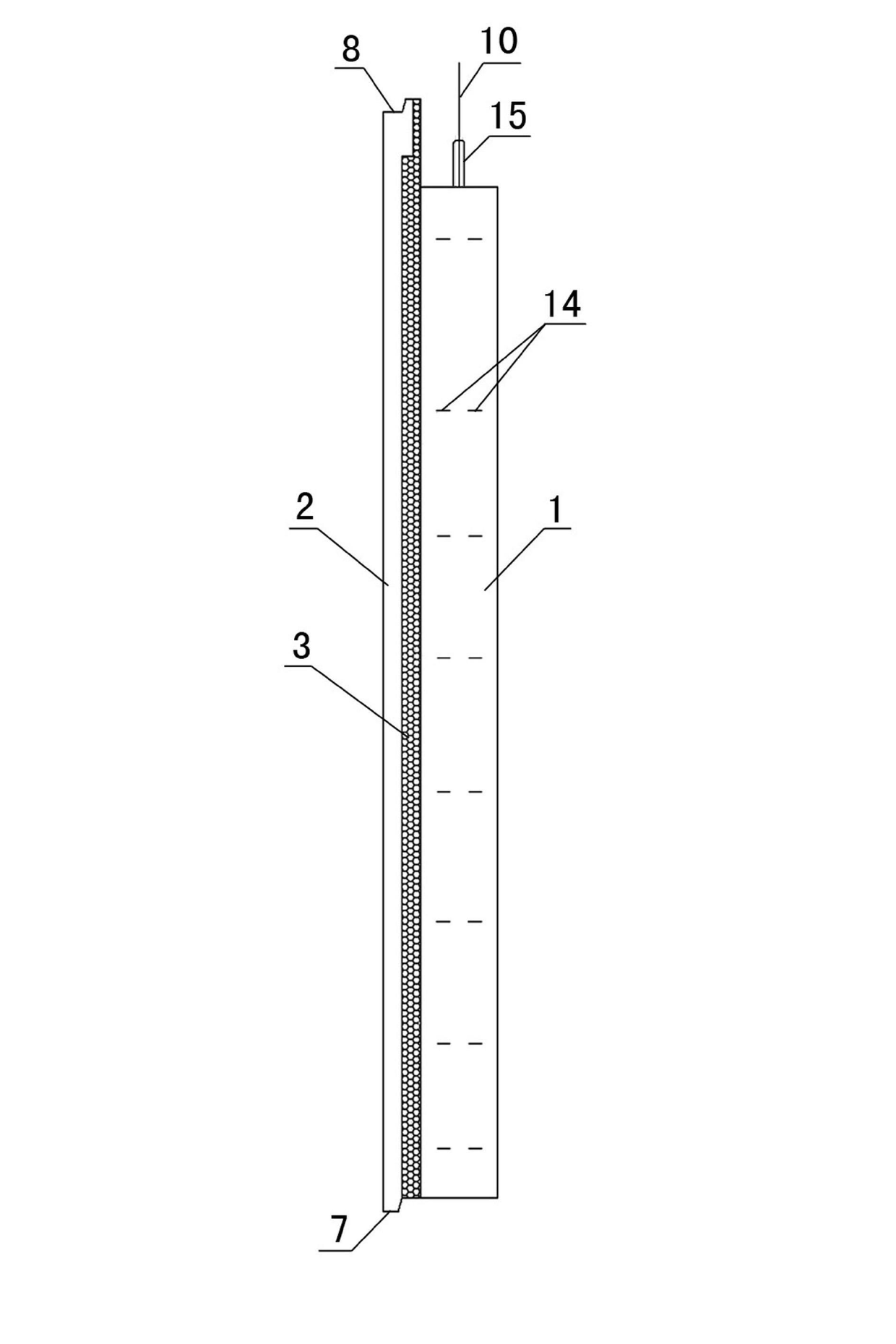

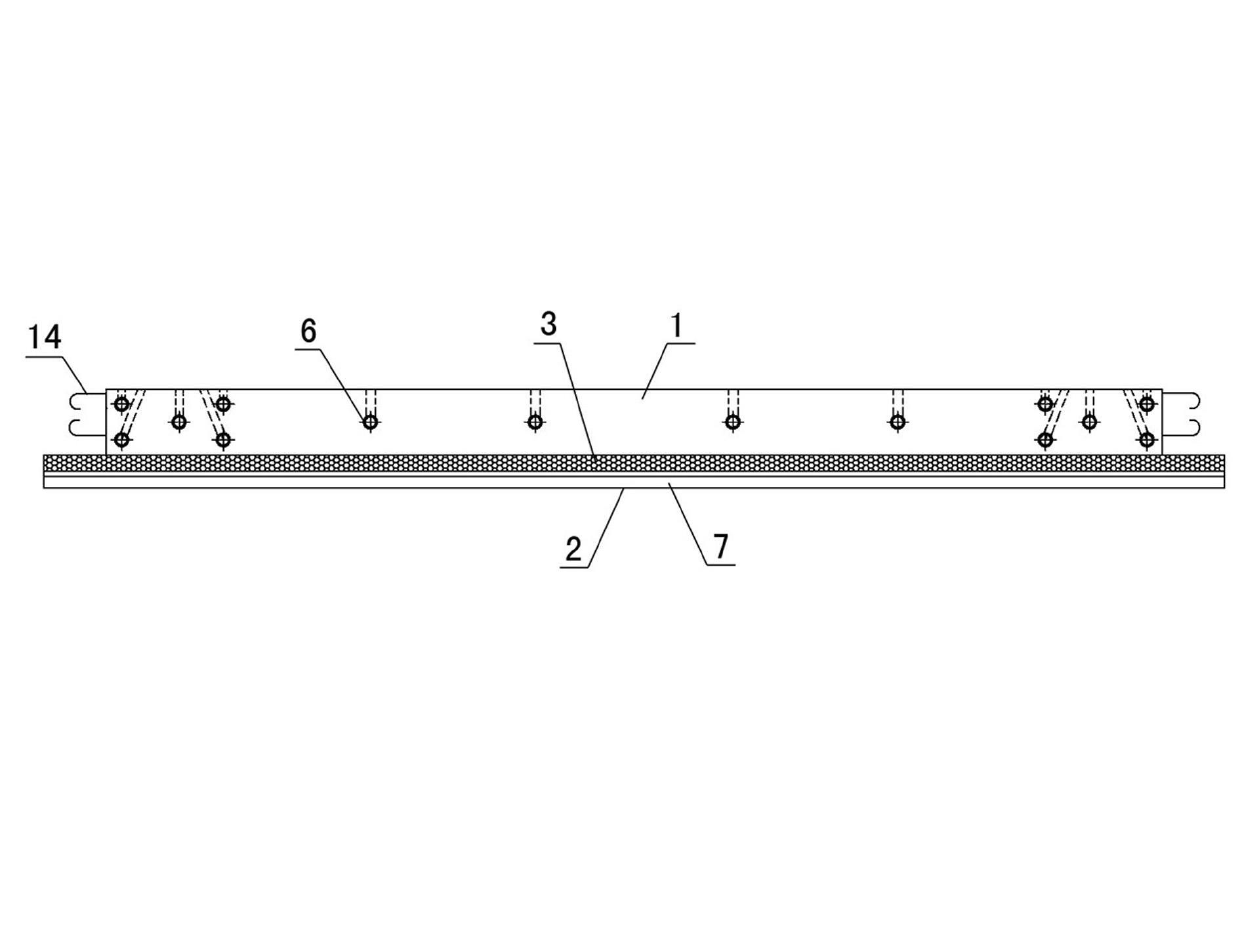

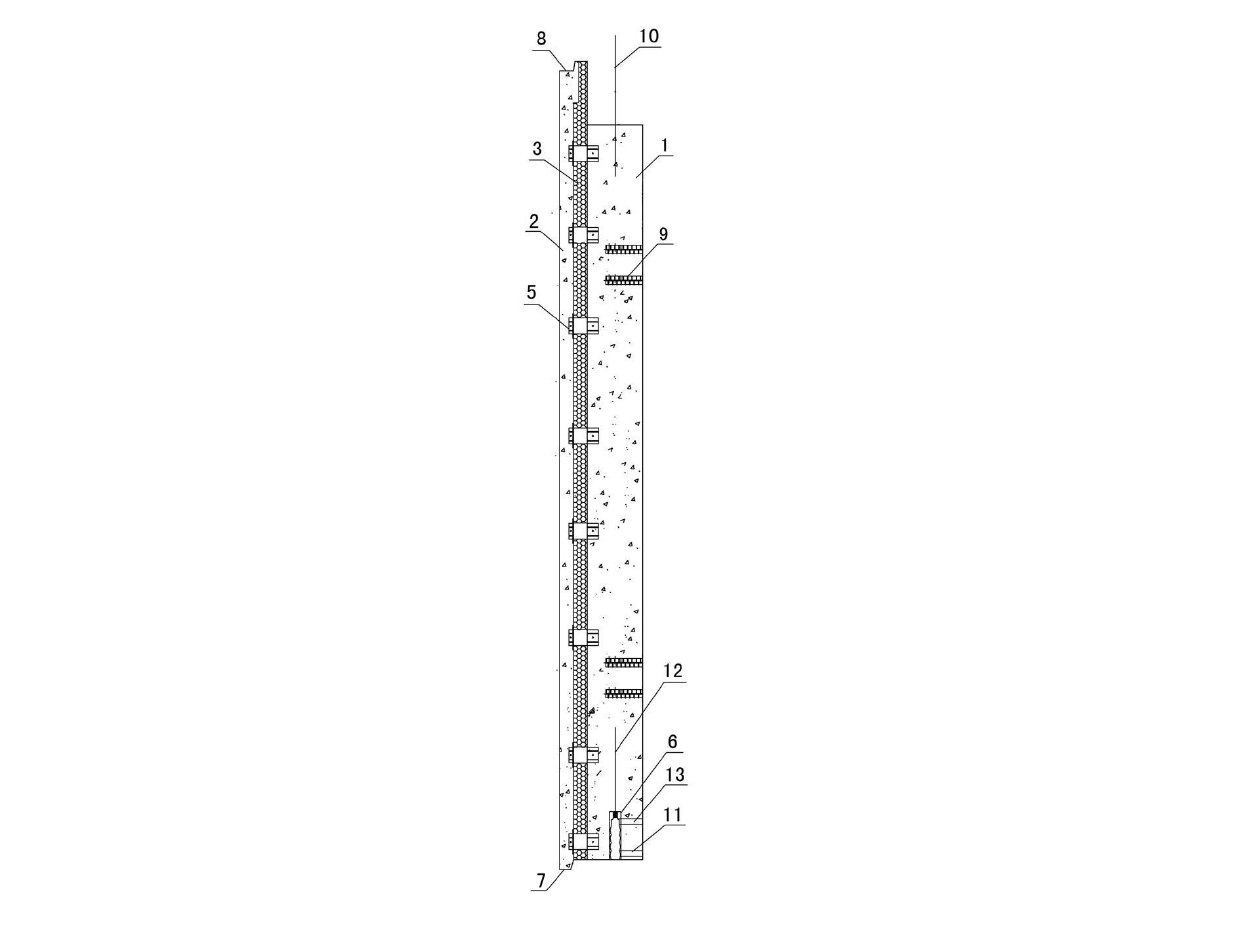

[0084] Embodiment one sees Figure 1-4As shown, this assembled integral shear wall structure system is hoisted and assembled by prefabricated composite wall panels at the construction site. The board body of each prefabricated composite wall panel has structural layer 1, insulation layer 3 and The protective layer 2 has a steel cage in the structural layer, and the concrete of the protective layer 2 has a steel mesh sheet. The structural layer 1, the thermal insulation layer 3 and the protective layer 2 are interspersed and anchored together by connecting pieces 5 distributed in dots. The left and right edges of the protective layer 2 and the thermal insulation layer 3 protrude from the structural layer 1, and the lower edge of the protective layer 2 extends downwards to form a protrusion 7, and the tops of the protective layer 2 and the thermal insulation layer 3 protrude upwards from the structural layer 1, and the protective layer The upper edge of the upper edge has a notc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com