Light steel keel for assembled door pocket

A light steel keel and assembly technology, applied in the field of light steel keel, can solve problems such as inability to ensure installation quality, difficulty in screwing nuts, and increased production costs, and achieve the effects of shortening the renovation period, avoiding paint pollution, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

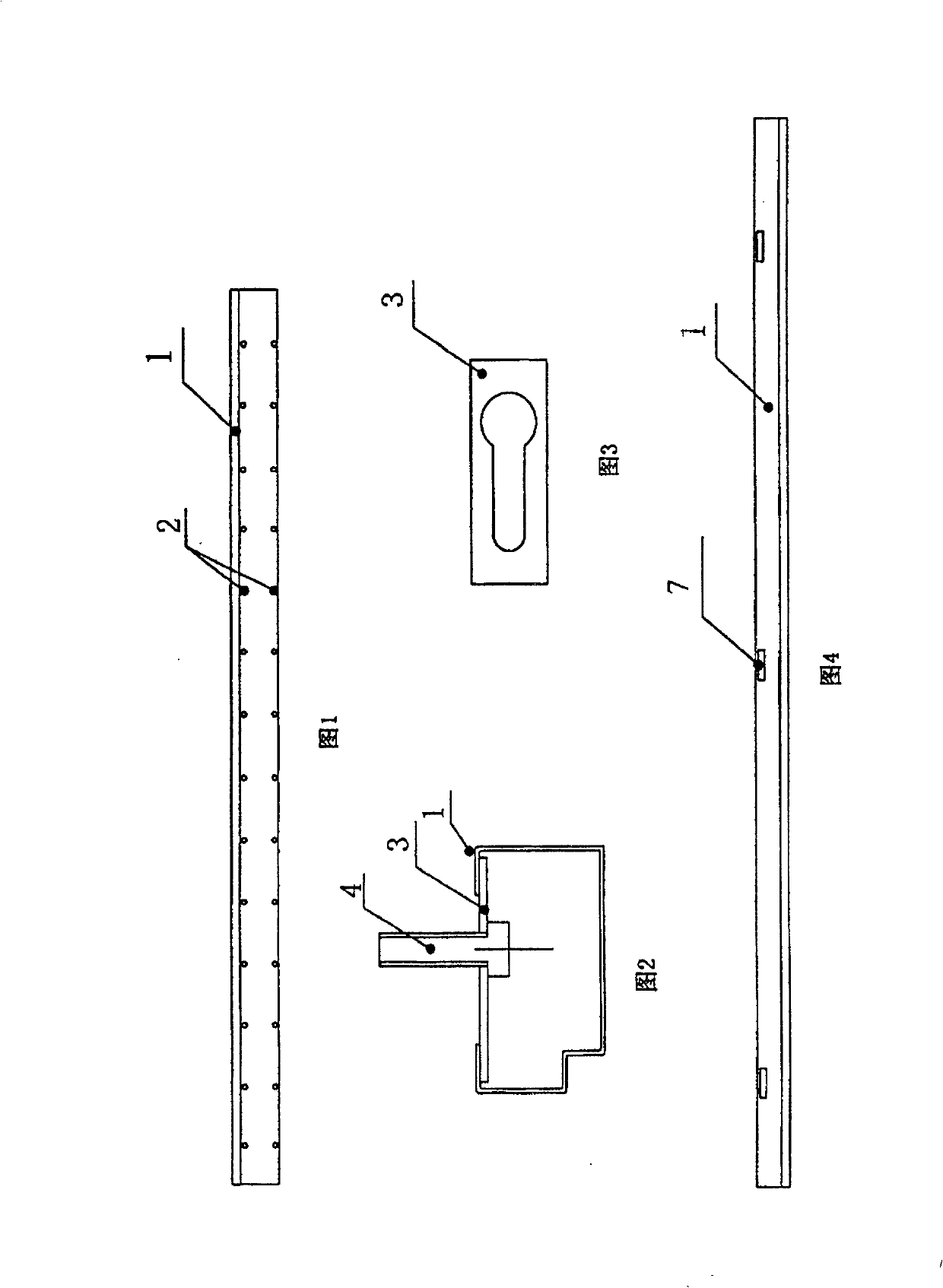

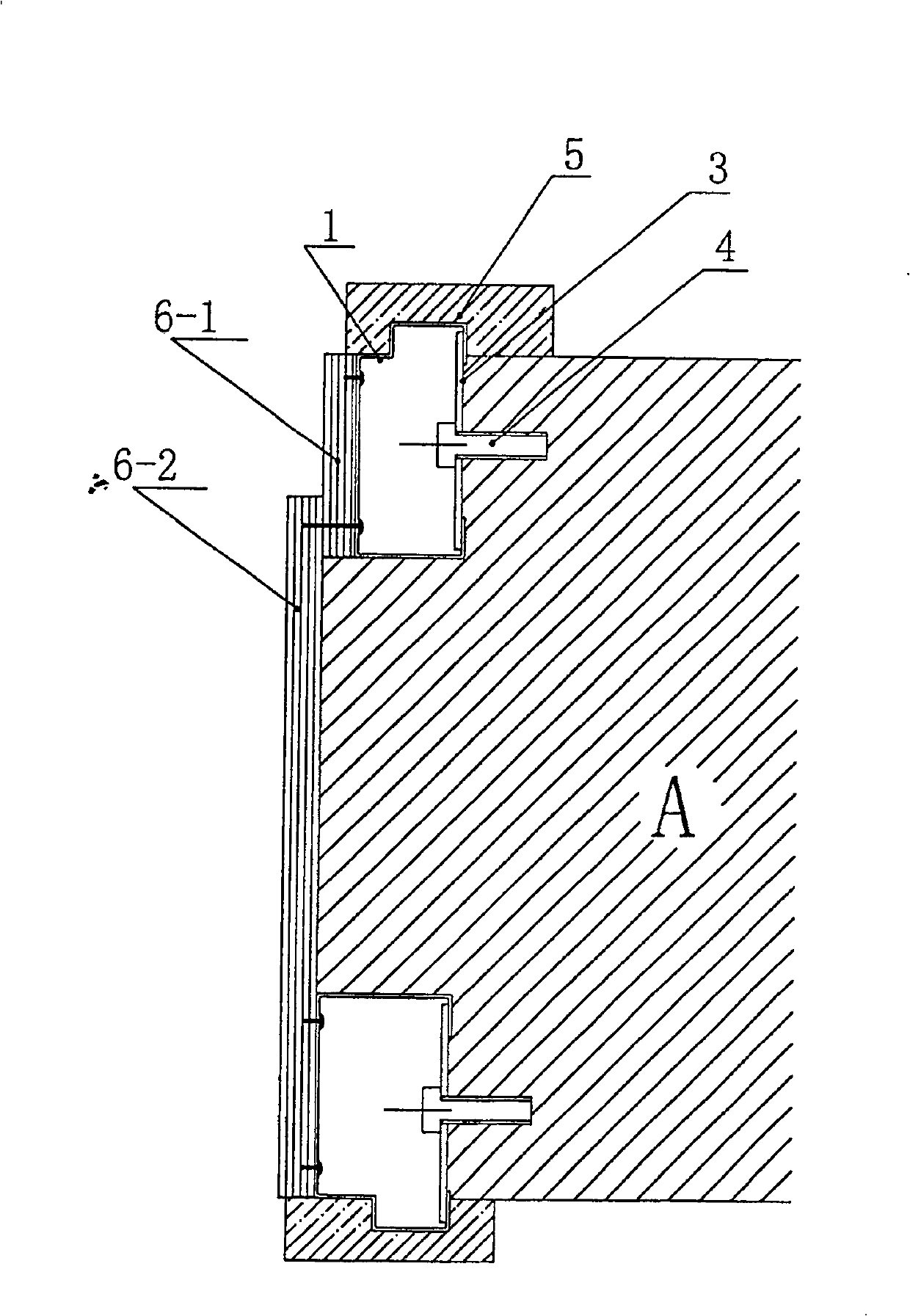

[0015] The shape of 1 of the light steel keel is There are fifteen assembly holes 2 for fixing the base plate on the upper and lower sides of the light steel keel 1. The upper surface of the light steel keel 1 is provided with three operating holes 7 and is equipped with three fixing parts 3. The upper surface of the light steel keel 1 is tightly bonded with the wooden molding 5 concave-convex.

[0016] Metal material for light steel keel material.

[0017] The production and installation procedures are as follows:

[0018] (1) According to the size of the door opening, determine the height, width and thickness of the door cover and cut out the base board and light steel keel of the required size. The first base board 6-1 and the second base board 6-2 are nailed through the gun connected, and processed into the size of the door cutout to form three boards with two long and one short boards; (2), on the two long sides of the back of the board, use self-tapping screws to asse...

Embodiment 2

[0019] Embodiment 2, the shape of 1 of the light steel keel is There are fifteen assembly holes 2 for fixing the base plate on the upper and lower sides of the light steel keel 1. The upper surface of the light steel keel 1 is provided with three operating holes 7 and is equipped with three fixing parts 3. The upper surface of the light steel keel 1 is tightly bonded with the wooden molding 5 concave-convex. Plastic steel is used as light steel keel material. Production and installation procedures are the same as in Example 1.

Embodiment 3

[0020] Embodiment 3, the shape of 1 of the light steel keel is There are fifteen assembly holes 2 for fixing the base plate on the upper and lower sides of the light steel keel 1. The upper surface of the light steel keel 1 is provided with three operating holes 7 and is equipped with three fixing parts 3. The upper surface of the light steel keel 1 is tightly bonded with the wooden molding 5 concave-convex. Plastic steel is used as light steel keel material. Production and installation procedures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com