Light-steel frame for assembled door pocket

A light steel keel, assembled technology, applied in the field of light steel keel, can solve the problems of difficult quality stability, difficult to correct flatness, easy loosening and deformation of door covers, etc., to avoid paint odor, high level and verticality, shape Smooth and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

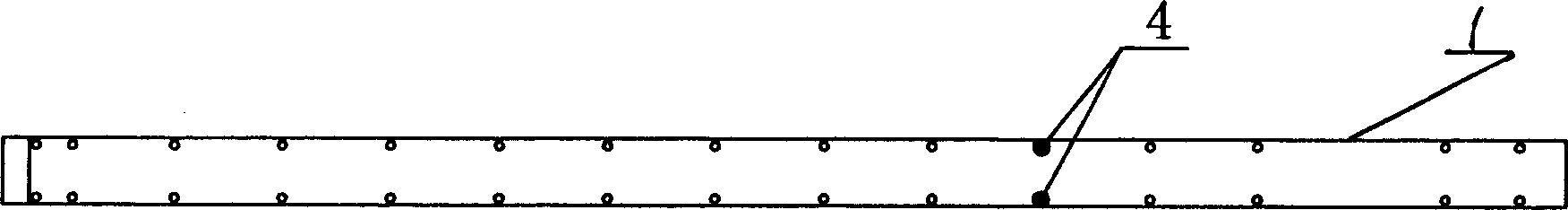

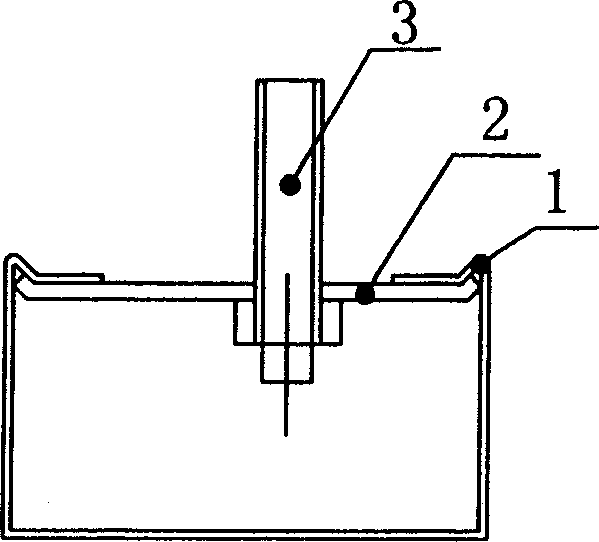

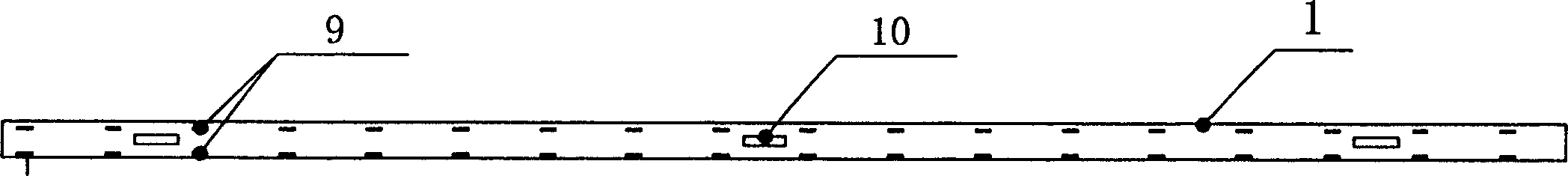

[0014] The structure of the light steel keel used for the assembled door cover is that there are several assembly holes 4 for fixing the base plate on the upper and lower sides of the front of the light steel keel 1, and there are respectively opened on the upper surface of the light steel keel 1. Holes 9, 10.

[0015] Examples, compared with the attached figure 1 , 2 , 3. Its structure is that there are fifteen assembly holes 4 for fixing the base plate on the upper and lower sides of the front of the light steel keel 1, and holes 9 and 10 are respectively opened on the upper surface of the light steel keel 1. The holes 9 has thirty-six, distributed on the upper and lower sides of the light steel keel 1 upper surface, the hole 9 is used for the assembly hole between the spring fastener 8 and the light steel keel 1, and there are three holes 10, which are connected with the The holes 9 are located on the same plane, and the holes 10 are operation installation holes for insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com