Installation structure and installation method of a ceiling board

A technology for installing structures and ceiling panels, applied in the direction of ceilings, building components, building structures, etc., can solve the problems of slow installation speed, complex installation structure, long decoration construction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

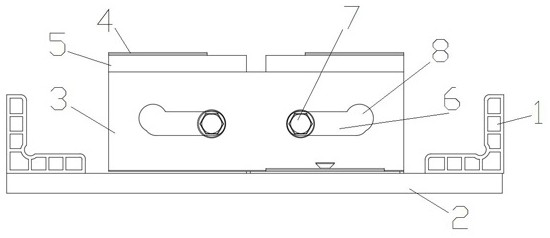

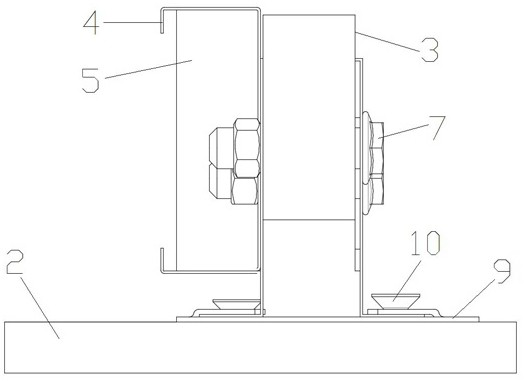

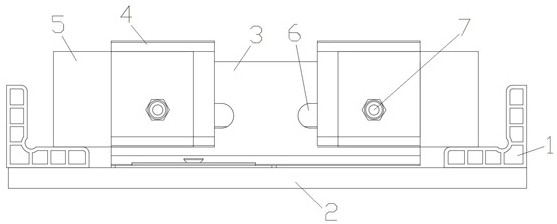

[0019] The specific implementation manner of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0020] like Figure 1-3 As shown, a ceiling panel installation structure includes a pair of L-shaped members 1 composed of vertical boards and horizontal boards, and the pair of L-shaped members 1 are relatively fixed on a pair of opposite side walls of the room. The outer walls of the vertical plates of the pair of L-shaped components 1 are respectively attached to the corresponding side walls, and the ceiling board 2 and a few-shaped keel 3 are also included, and the bottoms on both sides of the several-shaped keel 3 The side is fixedly connected with the top surface of the ceiling board 2, the several-shaped keel 3 is vertically arranged with the pair of L-shaped members 1, and the two ends of the several-shaped keel 3 are provided with C-shaped stainless steel sheets 4 And wooden block 5, described wooden block 5 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com