A kind of wall panel manufacturing process

A manufacturing process and wallboard technology, applied in the field of wallboard manufacturing technology, can solve the problems of a lot of material waste, difficult project management, and long material arrival time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

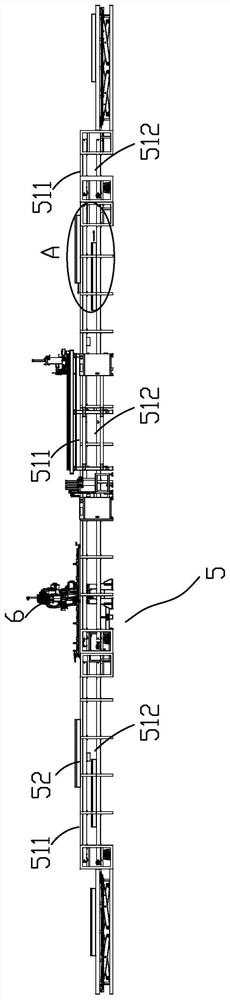

[0034] The present invention will be further described below in conjunction with accompanying drawing:

[0035] A kind of wallboard manufacturing process, comprises the steps:

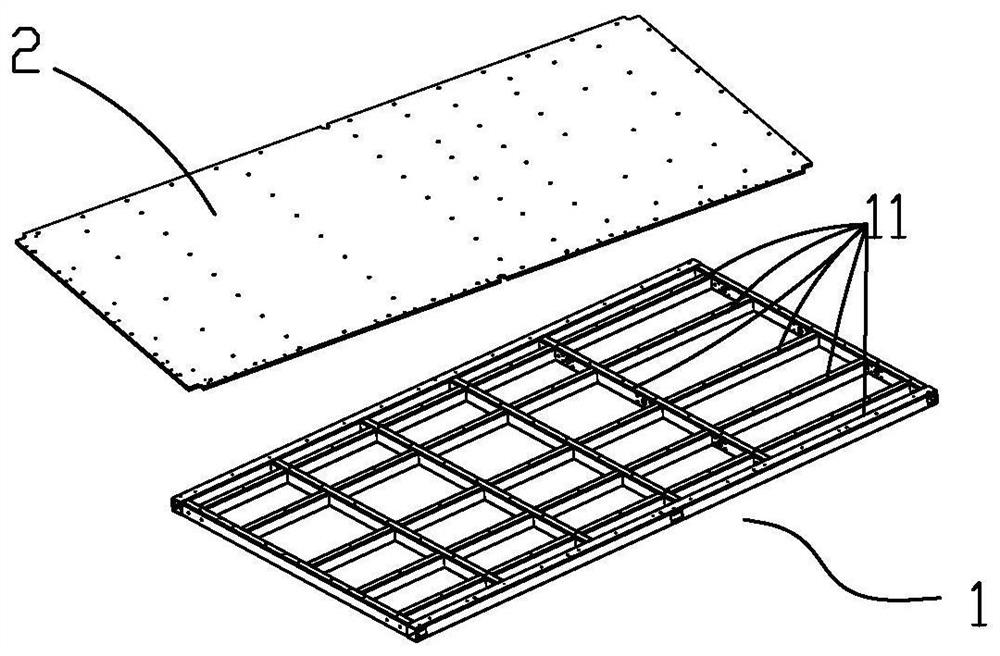

[0036] A: To make the keel assembly 1, the keel assembly 1 can be longitudinally formed by multiple square metal tubes

[0037] It is made of horizontal connection, which can be welded or screwed;

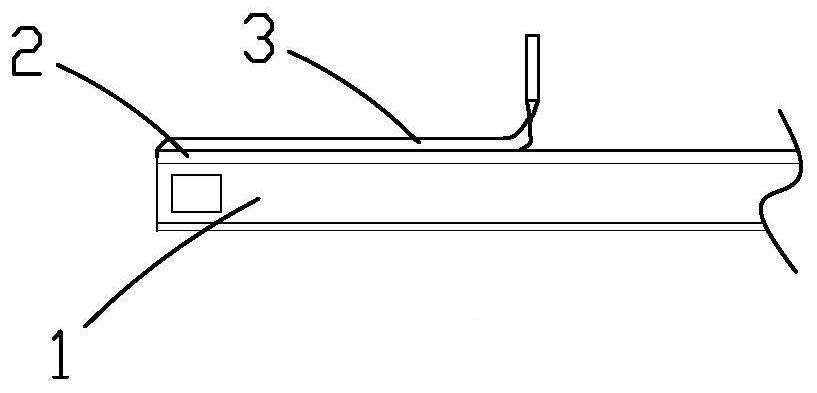

[0038] B: Fix the bottom plate 2 on the side of the keel component 1, the bottom plate 2 can be cement fiber board, and fix the bottom plate 2 to the keel component 1 by screws;

[0039] C: Apply adhesive glue 3 on the bottom plate 2;

[0040] D: Paste multiple tiles 4 on the bottom plate 2.

[0041] Therefore, the wall panel manufacturing can be completed in the factory workshop. When building a house for decoration, it is only necessary to transport several wall panels to the construction site and fix them on the wall, avoiding the process of cutting and pasting tiles on site. , Improve efficiency, fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com