Prefabricated assembly type decoration surface of house inner wall surface

A prefabricated assembly and interior wall technology, applied in covering/lining, construction, building construction, etc., can solve the problems of scrapping, poor environmental protection, poor environmental protection and energy saving effects, etc., and achieve cost reduction, good environmental protection, and less waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

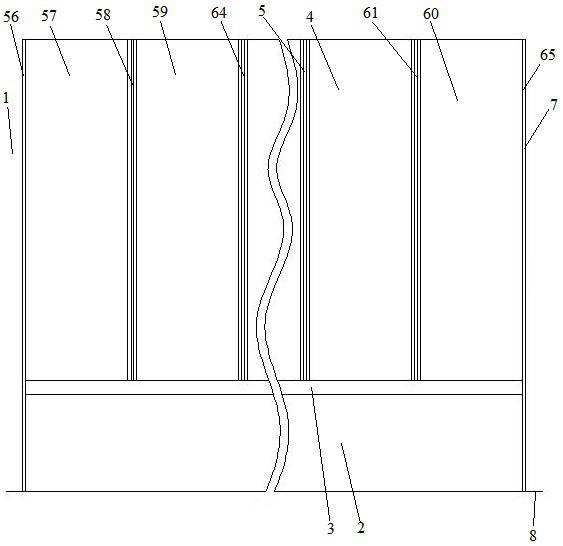

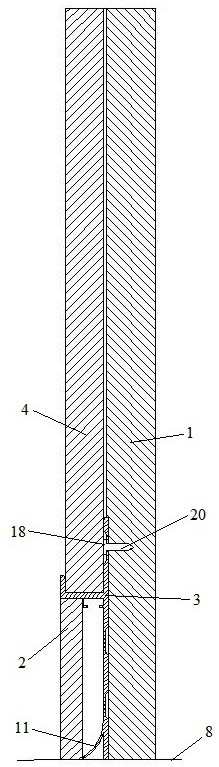

[0046] Embodiment one, see Figure 1 to Figure 7 , a prefabricated decorative surface of the interior wall of a house, comprising a wall 1, a skirting line 2, a supporting bottom bar 3 and several decorative panels 4 spliced together along the horizontal direction. The front and back of the decorative board are provided with decorative layers, that is, the front and back of the decorative board can face into the room to decorate the wall. Sealing strips 5 are provided at the seams between adjacent decorative panels. One end of the decorative board that is positioned at the most edge is connected with the wall through the edge strip 7 away from the remaining decorative board. The lower end of the support bottom bar is supported on the ground 8 .

[0047] The support bottom strip, the sealing strip and the edge strip are all fixed together with the wall by screws. The supporting bottom strip, the sealing strip and the edge strip are all profile structures.

[0048] Support...

Embodiment 2

[0051] Embodiment two, the difference with embodiment one is:

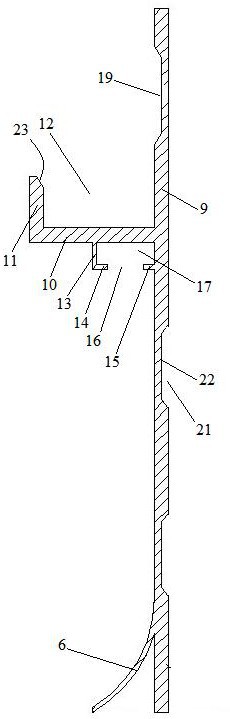

[0052] see Figures 8 to 11 The bottom surface of the connecting groove of the decorative panel of the sealing strip part is provided with a rubber strip 35 of the sealing strip part, which can offset the deformation caused by thermal expansion and contraction of the decorative panel through elastic deformation.

[0053]Both the side shielding strips and the side shielding strips are of elastic structure. A hook hole is provided on the leading-in inclined surface of the edge-wrapping strip. The hook hole includes an outer section 44 and an inner section 45 . The outer section is connected together with the inner section in a broken line structure. The projection of the inner section along the distribution direction of the edging strip and the back panel of the edging strip (that is, the direction along the thickness of the wall when used) and the leading-in slope of the edging strip along the shading strip of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com