Assembly method of assembly type medical unit

An assembly method and assembly technology, which is applied in the processing of building materials, fire protection, walls, etc., can solve the problems of complex assembly of modules, and achieve the effects of diversification of effects, uniform specifications, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

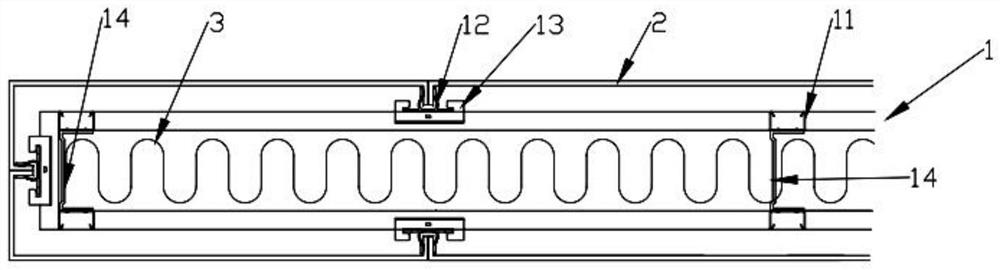

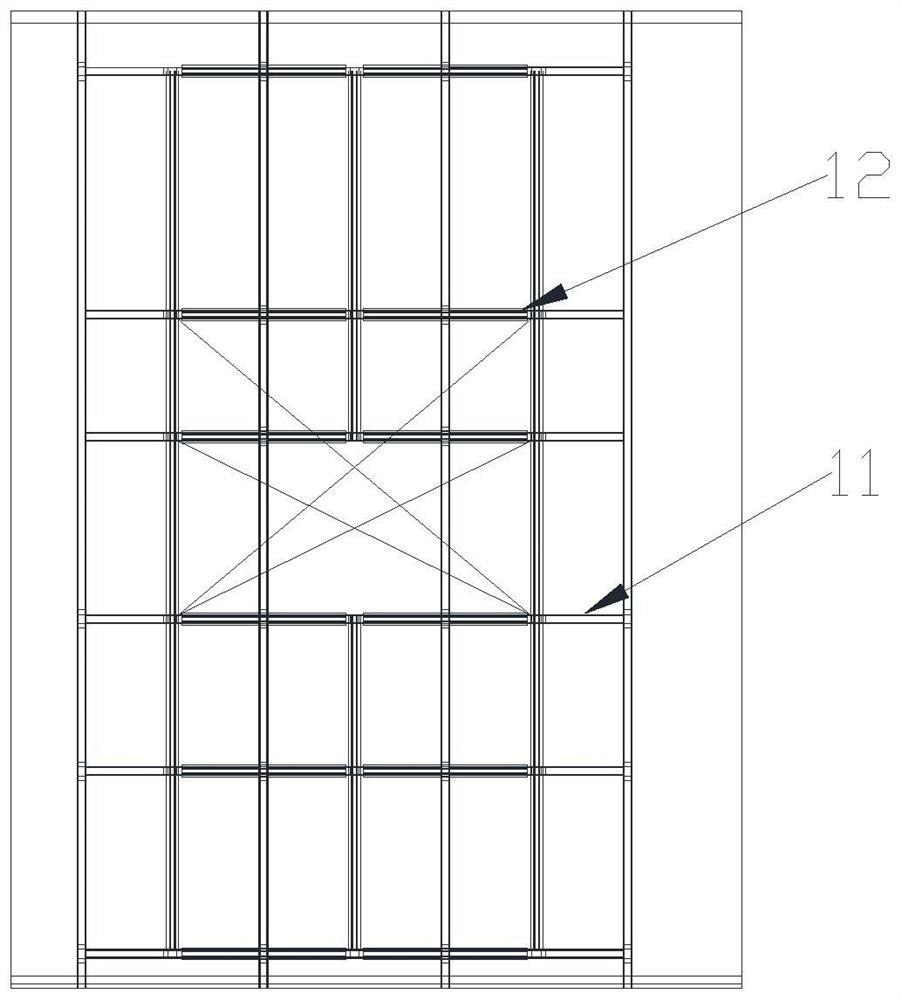

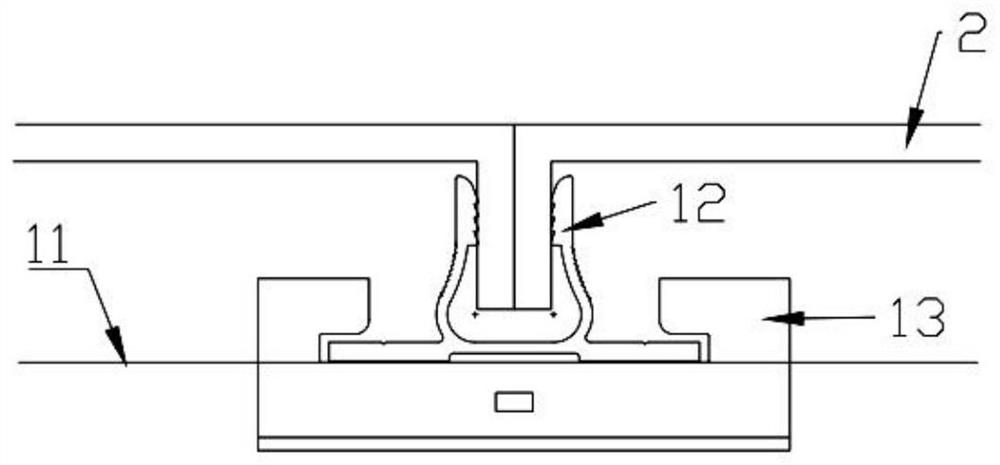

[0054] A specific embodiment of the present invention discloses a prefabricated medical wall, such as Figure 1-Figure 16 As shown, it includes a wall frame 1, a decorative panel 2 and a fireproof and soundproof cotton 3, wherein the wall frame 1 is used to support the entire wall; the decorative panel 2 is installed on the wall frame 1; the fireproof and soundproof cotton 3 is filled with The space formed by the wall frame 1 and the decorative panel 2 is used for fire prevention and sound insulation.

[0055] In this embodiment, the decorative panel 2 is fixed on the wall skeleton 1 by a plug-in type without bolts. This process can be quickly assembled and disassembled, reducing costs; the standard thickness of the prefabricated medical general wall is 150mm, which can be used according to medical The function is adjusted between 150-240mm, and the wall height is customized according to the actual indoor height.

[0056] It should be noted that the wall frame 1 includes a su...

Embodiment 2

[0083] The present invention also provides a method for assembling an assembled medical unit according to Embodiment 1, the steps comprising:

[0084] Step 1: Pay-out, pre-embed fixtures or components;

[0085] Step 2: Arrangement of the modular system of the assembled medical unit;

[0086] Step 3: Assemble each prefabricated medical unit module;

[0087] Step 4: Installation of sky keel and ground keel;

[0088] Step 5: The assembled medical unit module is connected to the sky keel and the ground keel.

[0089] details as follows:

[0090] In step 1, according to the construction drawing combined with the actual situation of the site, carry out on-site positioning and lay-out, actually measure the site's geometric dimensions, determine the position of the wall skeleton system according to the designed ceiling and structure height, and determine the wall skeleton system and the top surface of the main structure connection to ground.

[0091] In step 2, the actual size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com