Manufacturing method of arch hinge of steel arch bridge

A manufacturing method and technology for steel arch bridges, applied in arch bridges, bridges, bridge parts, etc., can solve the problems of low material utilization rate, high processing cost, long manufacturing cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

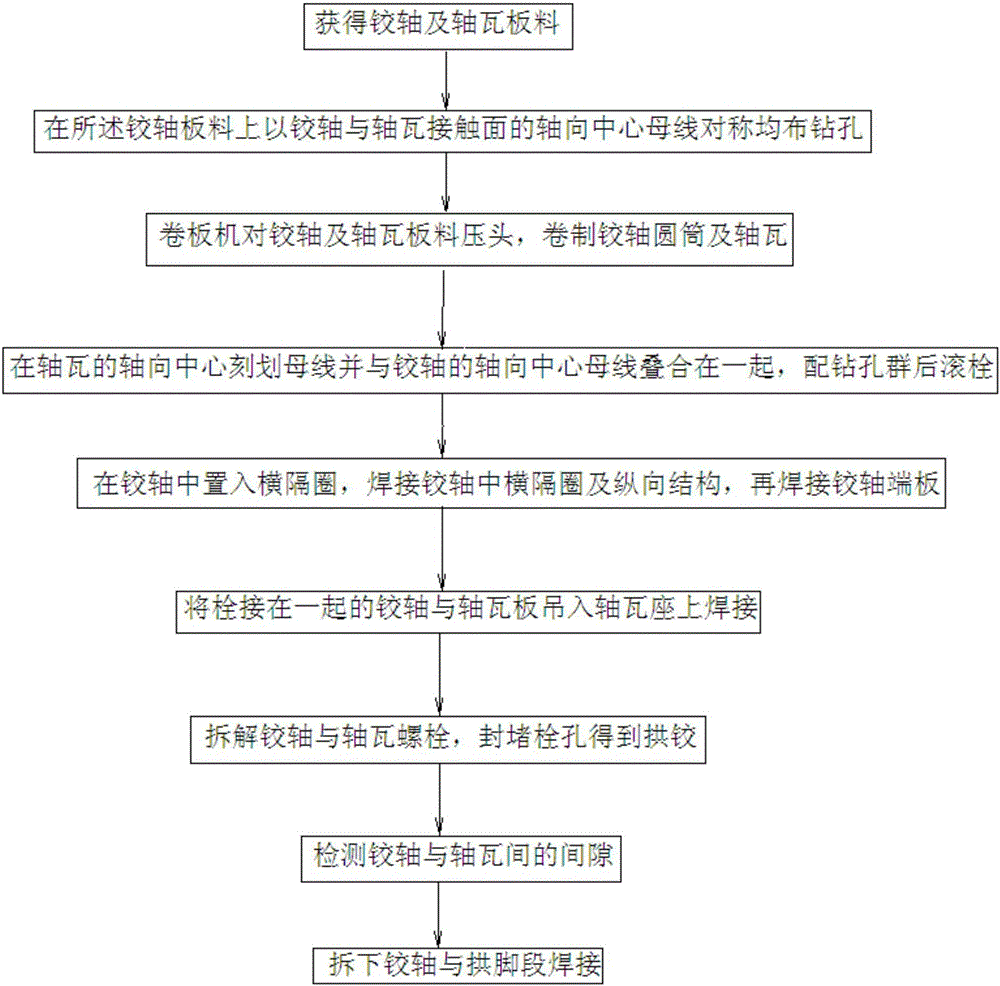

[0022] see figure 1 , a method for manufacturing an arch hinge of a steel arch bridge provided by an embodiment of the present invention is characterized in that it includes the following steps:

[0023] Step 1, obtain hinge shaft and bearing pad sheet.

[0024] Step 2, drilling holes symmetrically and evenly on the hinge shaft sheet material with respect to the axial central generatrix of the contact surface of the hinge shaft 1 and the bearing bush 2 .

[0025] Step 3, the plate rolling machine presses the hinge shaft and the bearing pad sheet material, and rolls the hinge shaft cylinder and the bearing pad.

[0026] Step 4: Scribe the generatrix on the axial center of the bearing bush 2 and superimpose it with the axial center generatrix of the hinge shaft 1, and equip the rear rolling bolt with the drilling group.

[0027] Step 5, put the diaphragm ring 3 in the hinge shaft, weld the diaphragm ring 3 and the longitudinal structure in the hinge shaft 1, and then weld the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com