Oxygen-enriched combustion method of volatilization klin

An oxygen-enriched combustion and inlet technology, applied in combustion methods, combustion equipment, fuel supply, etc., can solve the problems of incomplete volatilization of metals, high production costs, energy waste, etc., and achieve the effect of reducing fuel consumption and increasing volatilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

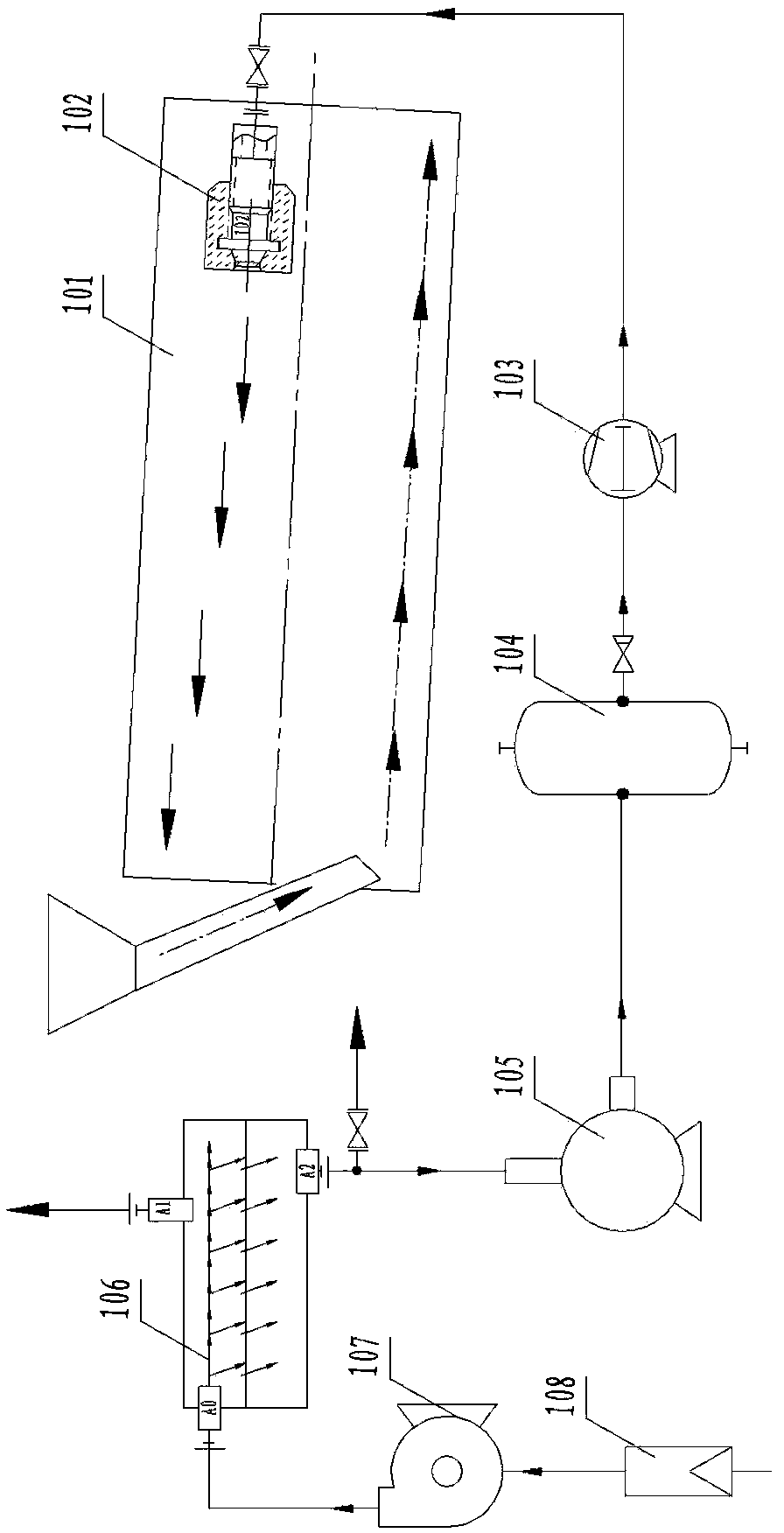

[0020] figure 1 The shown volatilization kiln oxygen-enriched combustion device includes a volatilization kiln 101, a nozzle 102 arranged in the inner cavity of the volatilization kiln, and a membrane separator 106; the inlet of the air filter 108 receives air, and its outlet communicates with the inlet of the high-pressure centrifugal fan 107, The outlet of the high-pressure centrifugal fan 107 is communicated with the inlet of the membrane separator 106, and an outlet of the membrane separator 106 is communicated with the dry Roots vacuum pump 105 through a pipeline, and the other outlet is used for exhaust gas; the dry roots vacuum pump 105 The outlet communicates with the inlet of the air storage tank 104 , the outlet of the air storage tank 104 communicates with the inlet of the air compressor 103 , and the outlet of the air compressor 103 communicates with the nozzle 102 .

[0021] The air filter 108 is equipped with two-stage high-efficiency filter cartridges. The first...

Embodiment 2

[0031] use figure 1 The shown volatilization kiln oxygen-enriched combustion device is used for production;

[0032] The oxygen-enriched combustion method of the zinc slag volatilization kiln includes three steps: batching, oxygen-enriched preparation, and air supply.

[0033] 1) Ingredients: ① Moisture requirement for mixture (leach slag, pulverized coal): 18%, initial leaching slag contains 20% water. ② Requirements for particle size of leach slag: 10-50 mm. ③Powdered coal is required to be anthracite, with 75% fixed carbon, 7% volatile matter and 25% ash. ④Powdered coal particle size composition: Less than 5mm accounts for less than 30%, 5-25mm accounts for more than 50%, and greater than 25mm accounts for less than 20%.

[0034] 2) Oxygen-enriched preparation is prepared by a membrane negative pressure oxygen device. In this embodiment, the power of the dry Roots vacuum pump 105 is 500 kilowatts, and the oxygen-enriched flow rate reaches 9000m 3 / h, the enriched oxygen...

Embodiment 3

[0038] figure 1 The shown volatilization kiln oxygen-enriched combustion device is used for production;

[0039] The oxygen-enriched combustion method of the zinc slag volatilization kiln includes three steps: batching, oxygen-enriched preparation, and air supply.

[0040] 1) Ingredients: ① Moisture requirement for mixture (leach slag, pulverized coal): 15%, initial leaching slag contains 25%. ② Requirements for particle size of leach slag: 10-50 mm. ③Powdered coal is required to be anthracite, with 70% fixed carbon, 5% volatile matter and 23% ash. ④Powdered coal particle size composition: Less than 5mm accounts for less than 30%, 5-25mm accounts for more than 50%, and greater than 25mm accounts for less than 20%.

[0041] 2) Oxygen-enriched preparation is prepared by membrane method negative pressure oxygen device. In this example, the power of dry Roots vacuum pump 105 is 300 kW, and the oxygen-enriched flow rate reaches 6000m 3 / h, the enriched oxygen concentration is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com