Fluid cooling system of a combustion engine charged by a turbocharger and method for cooling a turbine housing of a turbocharger

A technology of liquid cooling and turbine cover, applied in liquid cooling, engine cooling, coolant flow control, etc., can solve the problem of no coolant input and output design, and achieve the effect of reducing heat load and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

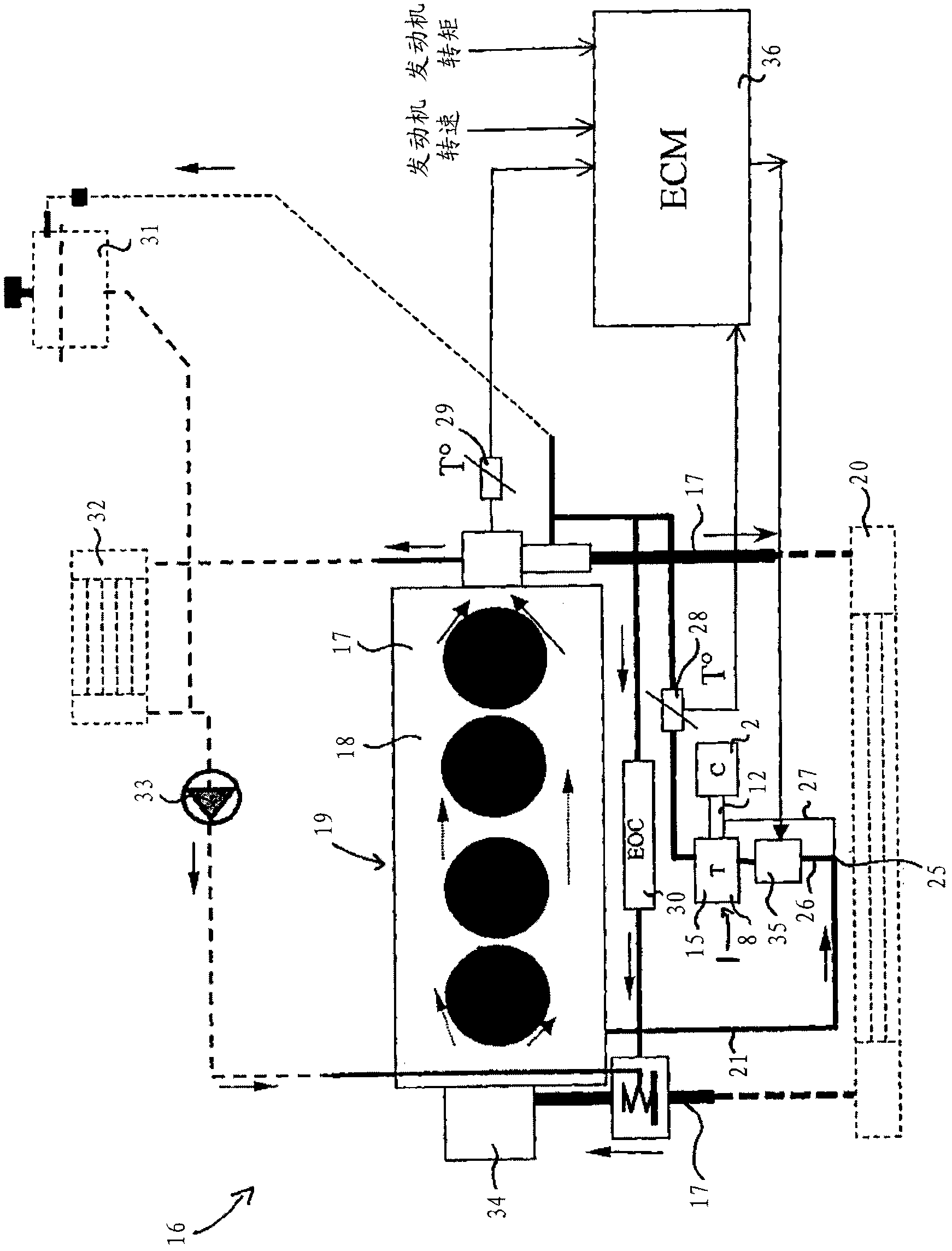

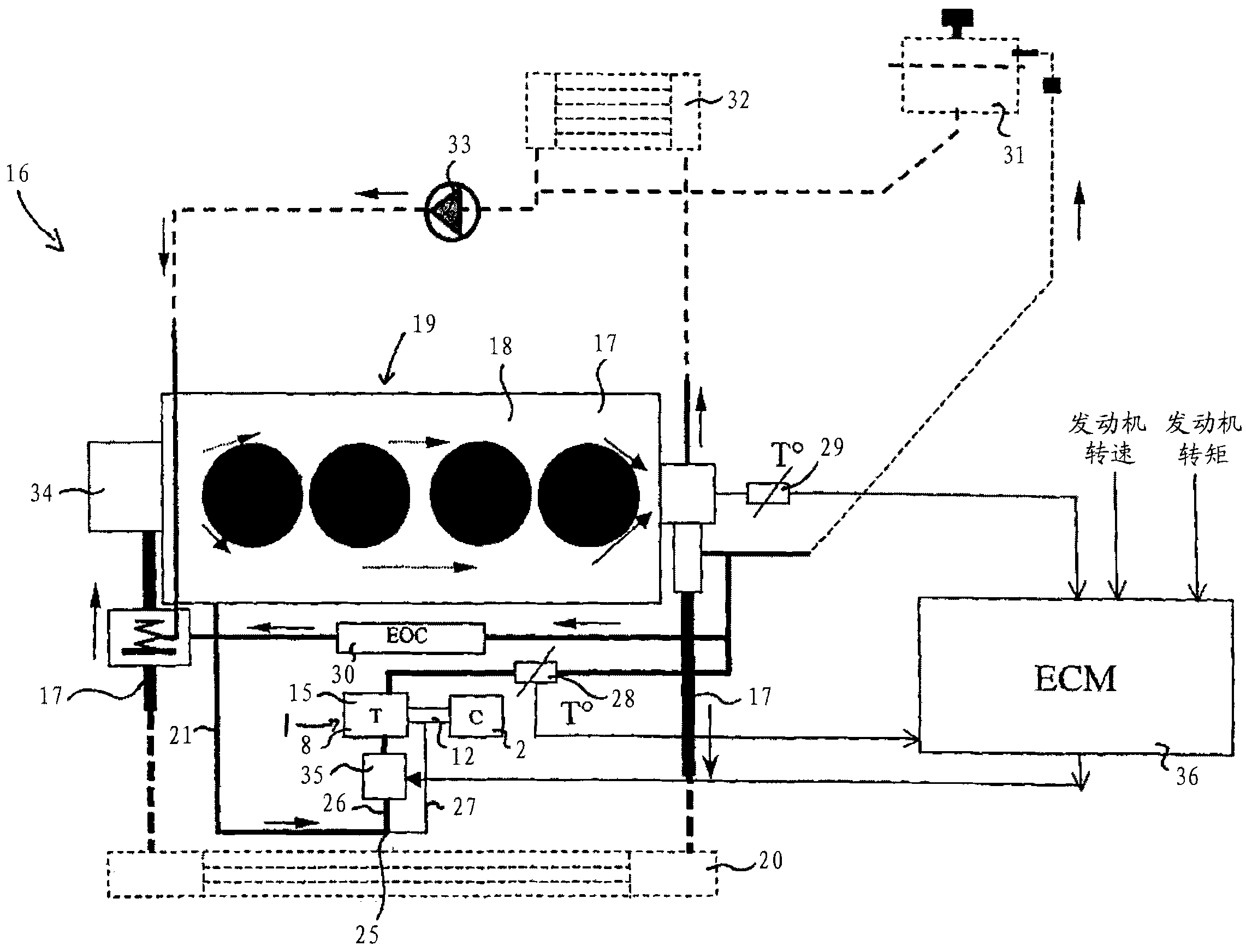

[0028] The same parts are provided with the same reference signs in both figures.

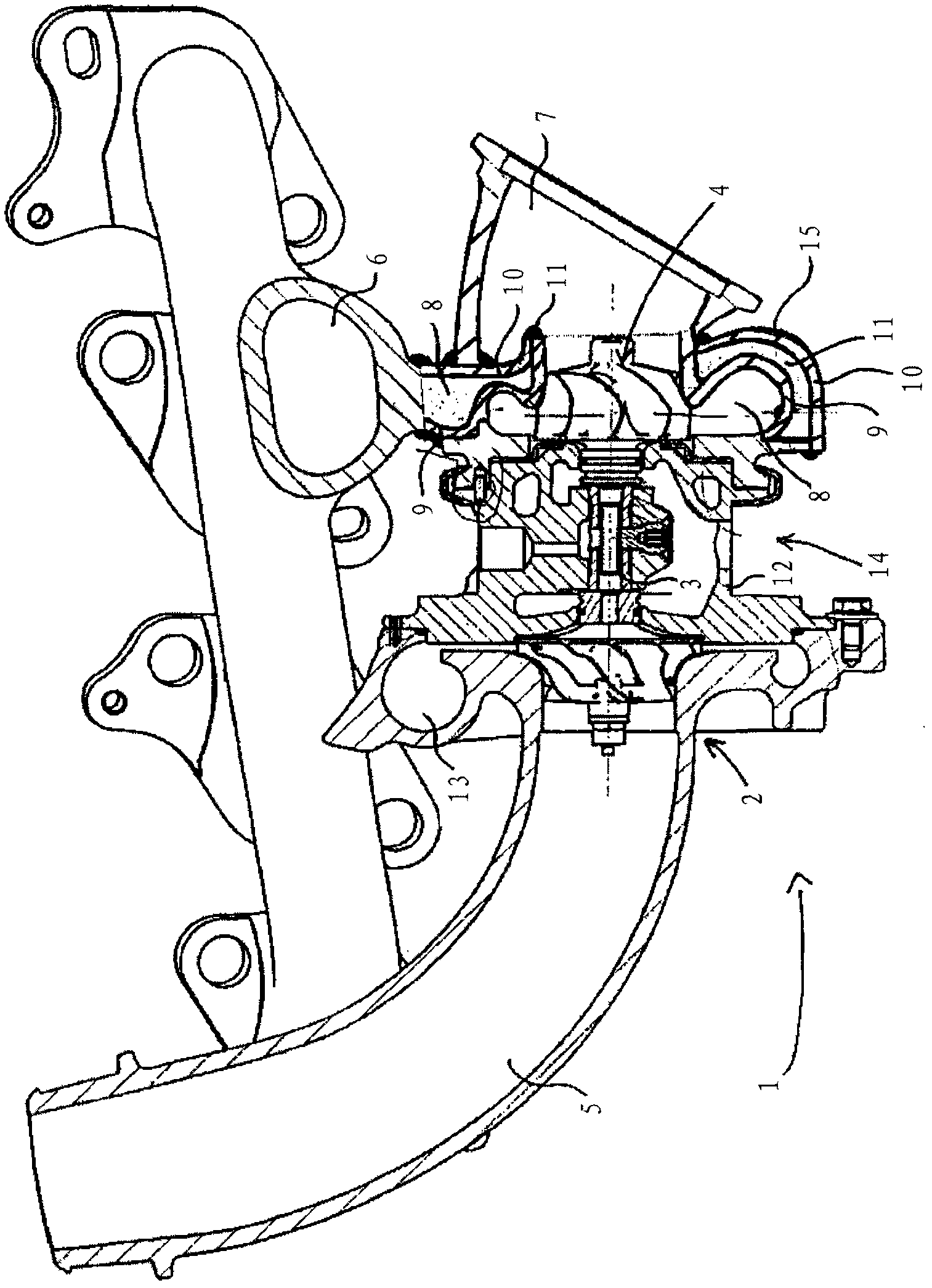

[0029] press figure 1 The turbocharger 1 has a compressor 2, a turbine 4, and a shaft 3 connecting the compressor 2 and the turbine 4. The shaft 3 is supported in a turbine bearing housing 12 by a turbine bearing 14.

[0030] The fresh air input through the air inlet 5 is compressed in the compressor 2 and output through the air outlet 13 and can be used in the intake passage of the internal combustion engine. The energy of the exhaust gas entering the turbine 4 through the exhaust gas inlet 6 is used to operate the compressor, in which the pressure of the exhaust gas drops, and the turbine causes the exhaust gas to exit through the exhaust gas outlet 7 again.

[0031] In operation, the turbine cover 15 is strongly heated by the hot exhaust gas. The turbine cover 15 is configured as a double wall having an inner wall 9 and an outer wall 10, wherein a cooling jacket 8 in which a coolant, such as wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com