Hydraulic and mechanical automatic speed variator

A technology of automatic transmission and hydraulic machinery, applied in the direction of transmission, fluid transmission, mechanical equipment, etc., can solve the problems of high cost and complex production process, and achieve the effect of low production cost, improved comfort, and improved ride comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific content of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

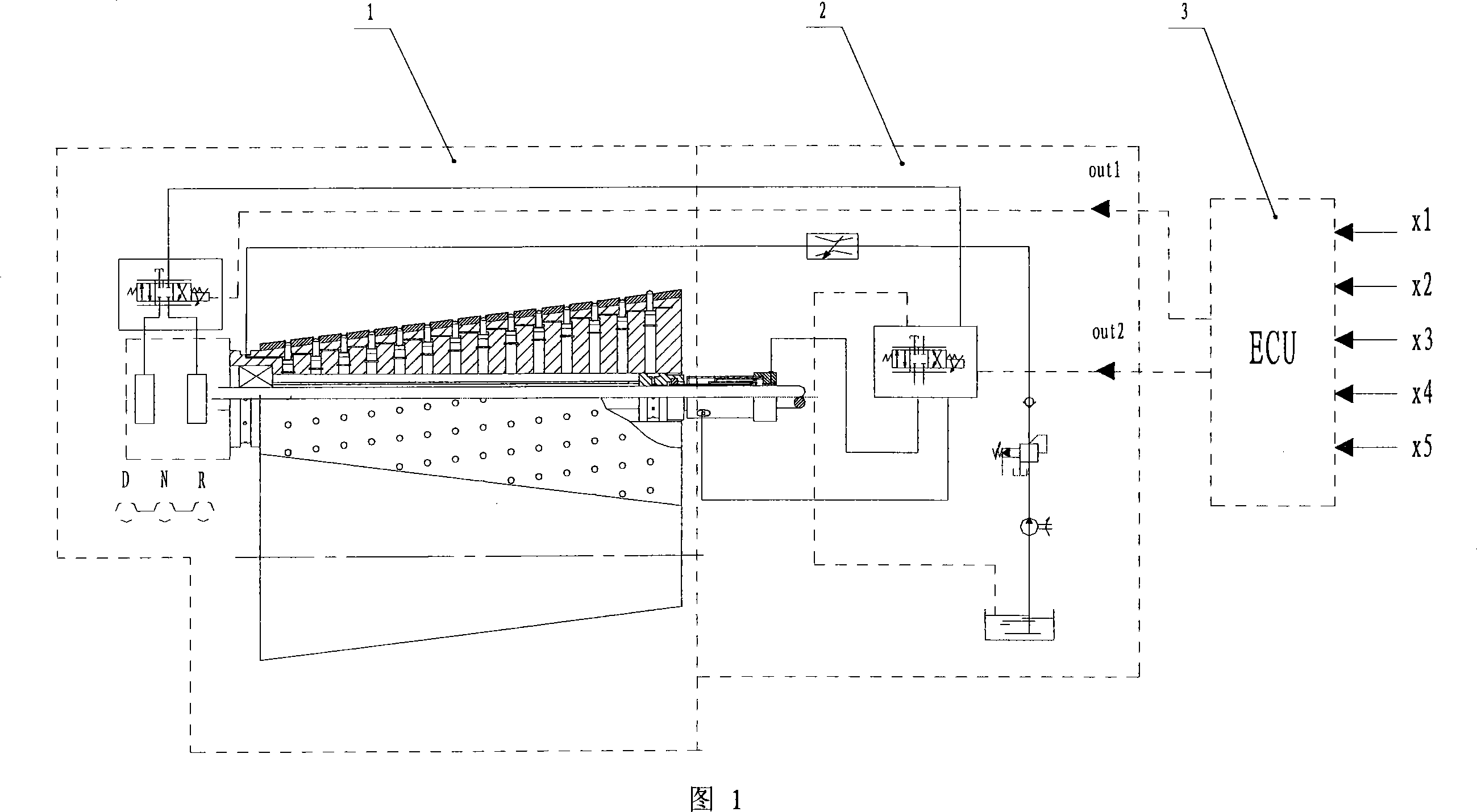

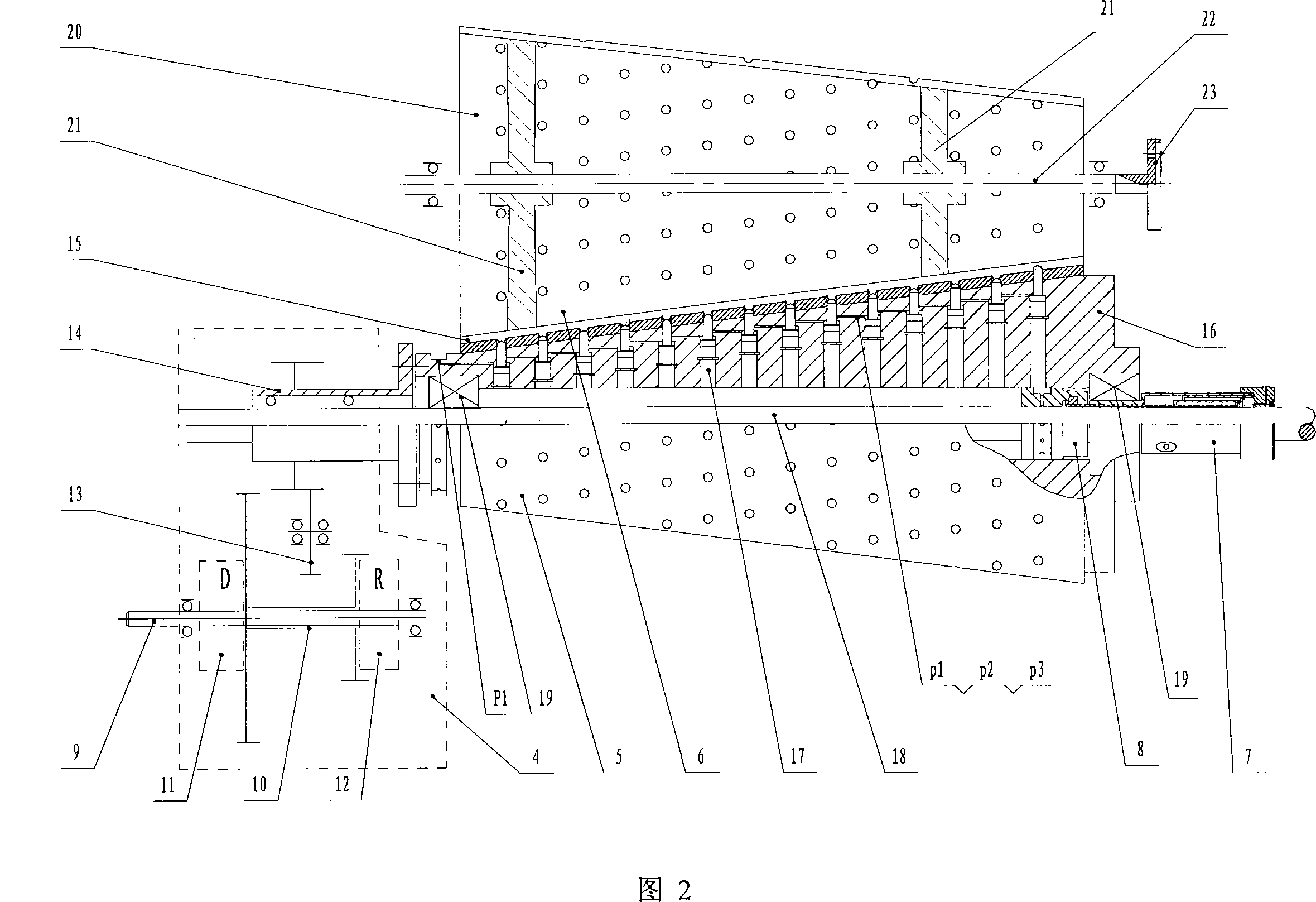

[0035] The hydromechanical automatic transmission device is mainly composed of a transmission part 1, a hydraulic control part 2 and a control unit 3. The said control unit 3 is connected with the transmission 1 and the hydraulic control part 2 respectively. The transmission part 1 is composed of a gear box 4, a driving frustum body 5, a driven frustum body 6, a shift selection cylinder 7, and a shift piston 8.

[0036] The technical solution provided by the invention has the following main technical features:

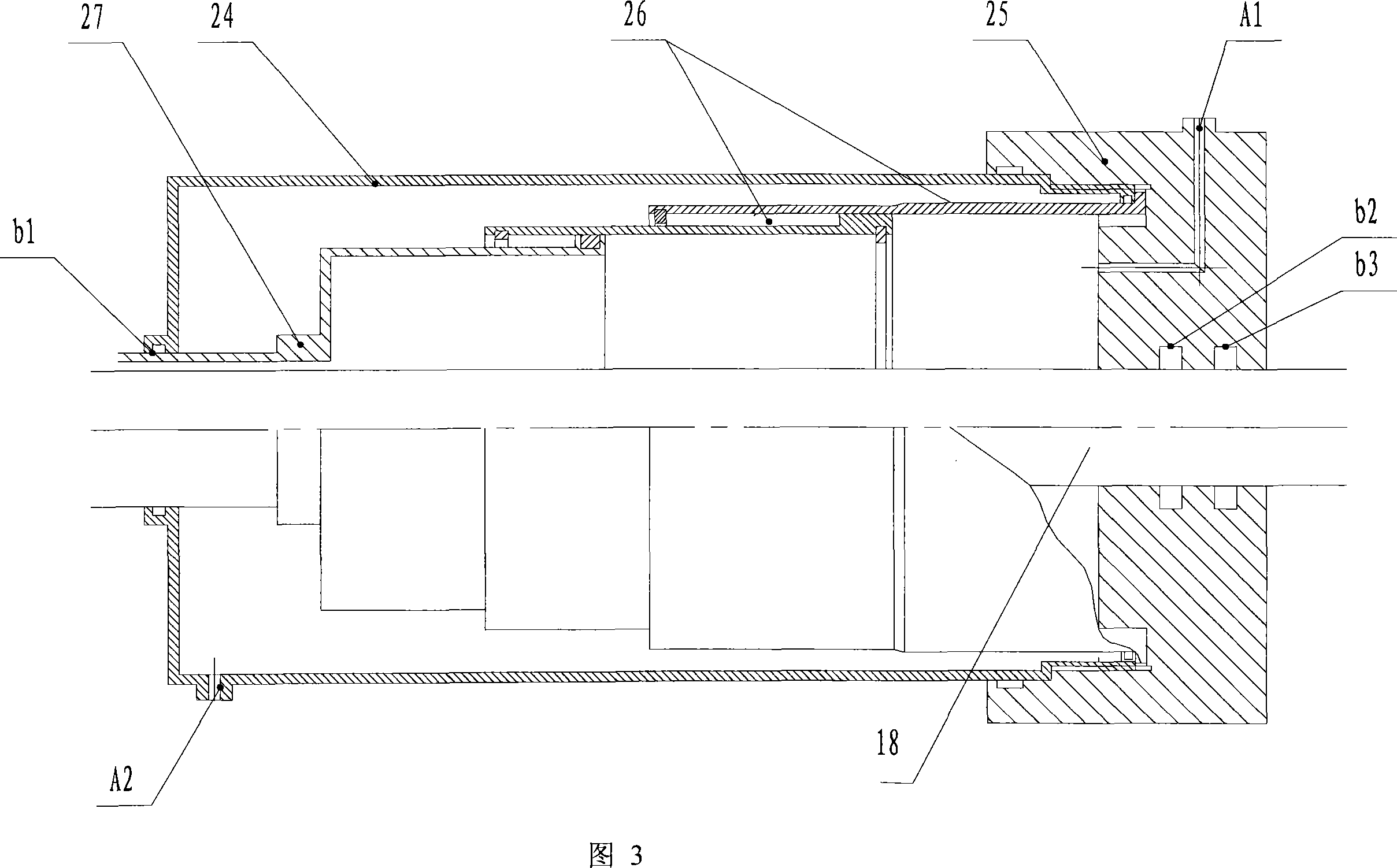

[0037] A. The external structures of the two truncated cones are consistent, and they are installed upside down on the axes parallel to each other. The surfaces of the two truncated cones are in contact, and the plunger in one of the truncated cones is moved out of its surface to make it Interlocking with anoth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com