Single-engine single-propeller type gas-electric hybrid ship power system

A power system, single propeller technology, applied in ship propulsion, mechanical gear transmission, ship parts, etc., can solve the problems of battery capacity limitation of endurance, unable to achieve high-performance speed acceleration and self-control, and achieve improved acceleration and deceleration. performance and reversal performance, improved reliability and serviceability, extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present invention will be described in more detail with examples in conjunction with the accompanying drawings:

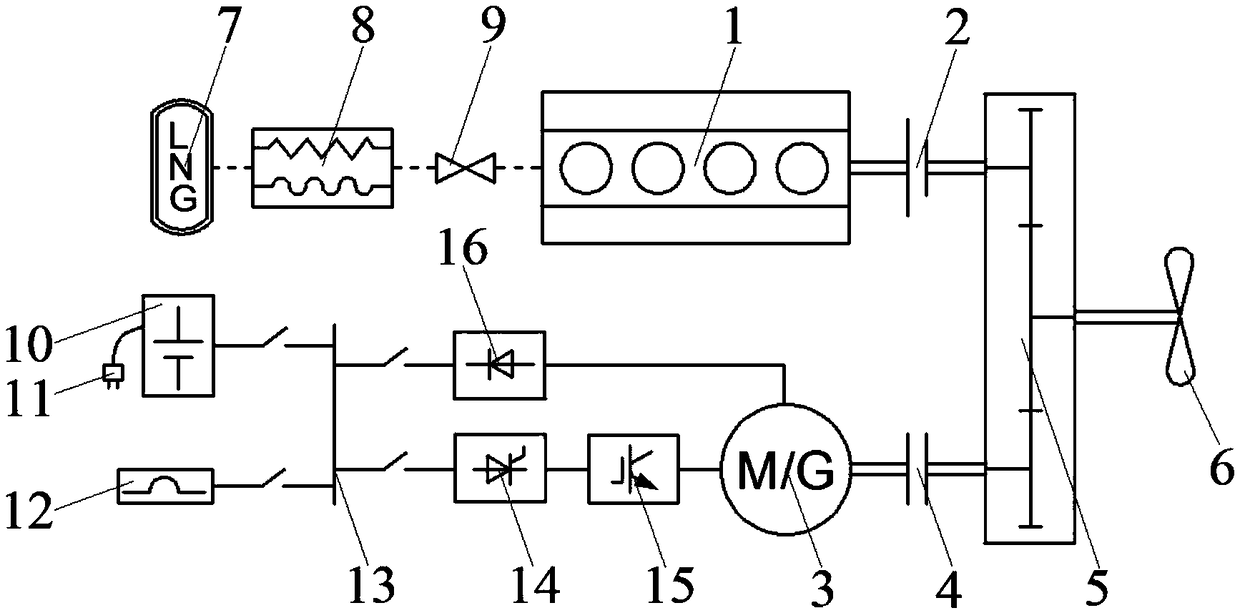

[0028] Combine figure 1 , The present invention is a single-engine single-propeller gas-electric hybrid ship power system, including a gas engine 1, a permanent magnet coupler 2, a reversible motor 3, a clutch 4, a gear box 5, a propeller 6, a liquefied natural gas tank 7, and a gas supply device 8. , Gas valve 9, battery 10, charging plug 11, ship load 12, switchboard 13, inverter 14, inverter 15, rectifier 16. The connection relationship is: the output end of the gas engine 1 is connected to one input end of the gearbox 5 through the permanent magnet coupler 2, and the output\input end of the reversible motor 3 is connected to the other input\output end of the gearbox 5 through the clutch 4 , The output end of the gear box 5 is connected to the propeller 6, the LNG tank 7 is gas connected to the gas supply device 8, and the natural gas is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com