Residual heat utilization device of boiler heat smoke method of using same

A technology of waste heat and hot smoke, which is applied in the field of waste heat utilization of boilers in industrial factories, can solve problems such as resource loss, waste, and environmental pollution, and achieve the effect of saving energy and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

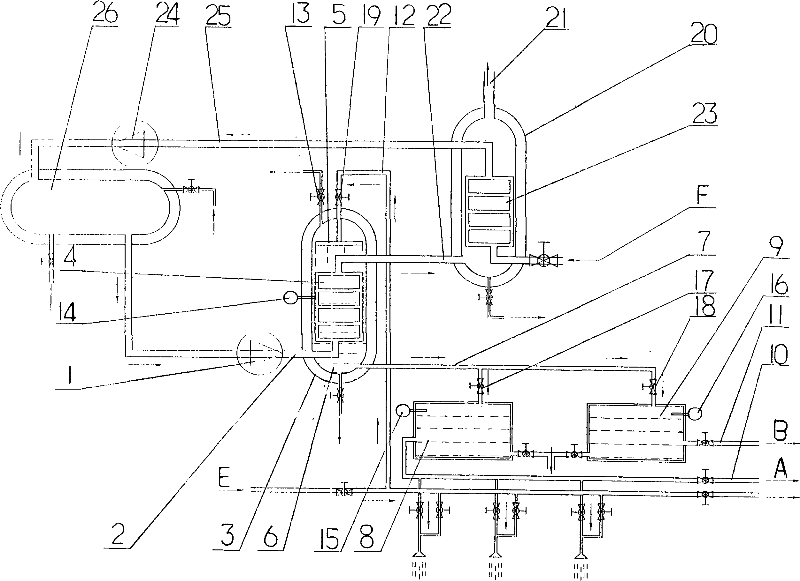

[0011] This embodiment is applied to a coal-fired boiler hot smoke waste heat utilization device with a heat production of 1 million Kcai / h per hour. It is a set of boiler hot smoke waste heat utilization device combined according to the structure of the attached drawing. Water generation tower, air preheating tower, exchanger, liquid level gauge, blower, hot water tank for production, hot water tank for domestic use, valves and pipelines, all components are standard parts purchased in the market, among which: Adopt 3.7KW×4P×1490rpm induced draft fan 1 to send the hot smoke into 20M through the hot smoke output pipeline 2 with a diameter of ∮500mm 3 The hot water generation tower 3, through 200M 2 The heat exchanger 4 transfers the heat to the tap water sprayed by the 0.45m / min sprinkler 5 to form hot water 6, and the hot water 6 is sent to 20M through the hot water output pipeline 7 with a diameter of ∮80mm 3 The domestic hot water tank 8 and the production hot water tank 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com