Coking furnace heating method and device capable of reducing generation of NOx

A heating device and heating method technology, which are applied to the heating of coke ovens, coke ovens, combustible gas heating coke ovens, etc. Effects of heat loss and NOx reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

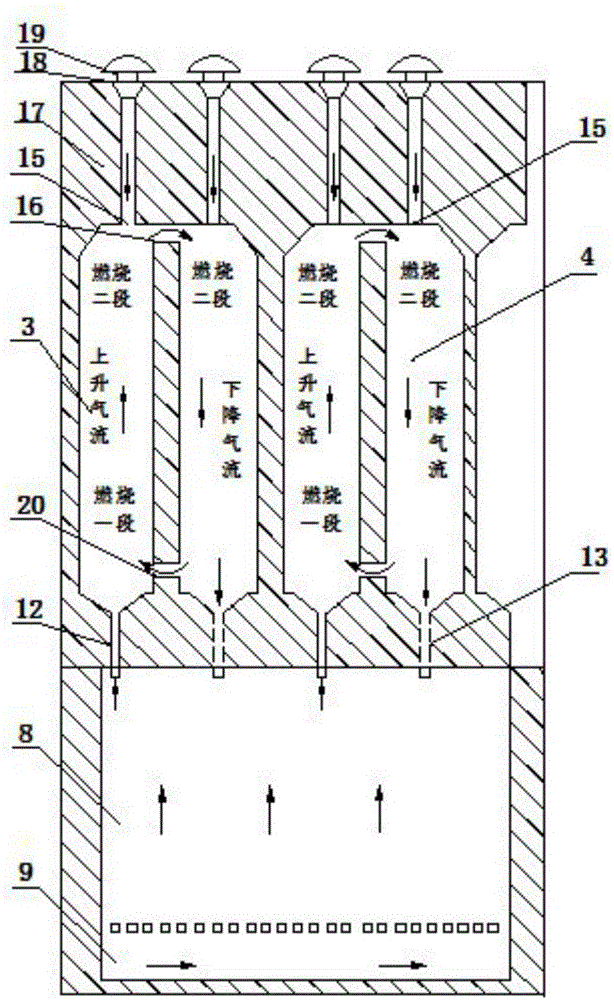

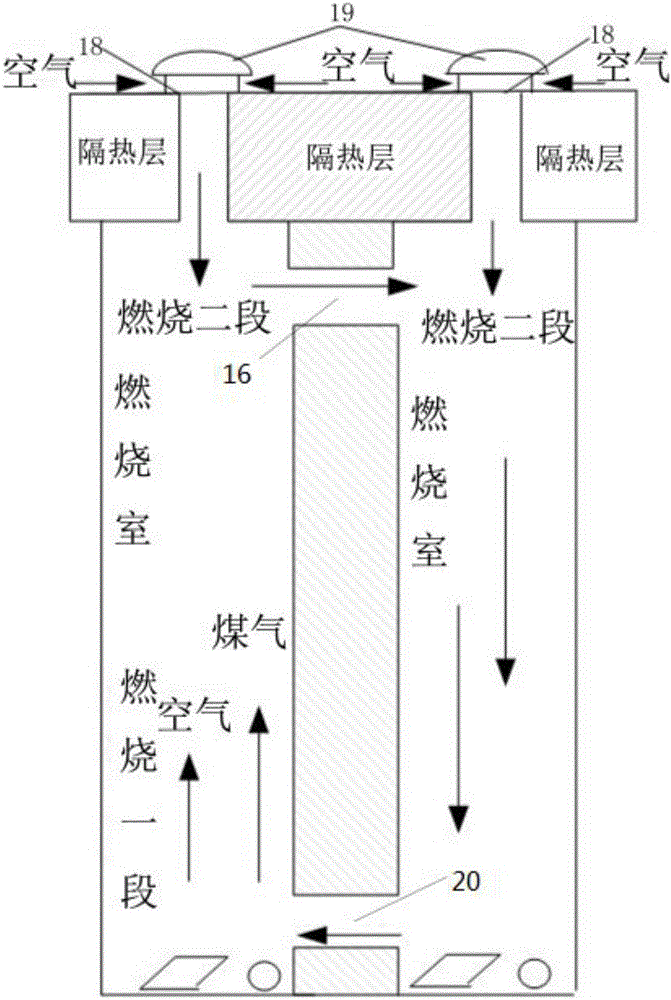

[0041] After the coke oven is heated and exchanged, the coke oven gas sprayed from the bottom to the top burns at the bottom of the vertical fire channel 3, that is, a section of combustion. The biggest feature of combustion in this area is that the ratio of air and gas is 70%-80%. The insufficient combustion reduces the flame temperature and inhibits the generation of thermal nitrogen oxides. A part of the unburned coke oven gas is burned for the second time on the upper part of the updraft vertical fire 3 with the air supplied from the adjustable air inlet flap 19 on the top of the furnace. The adjustable air inlet flap 19 is arranged in the fire viewing hole. On the hole cover of 18, a flap or manual adjustment valve is installed inside to adjust the air flow, and the air inlet flap 19 (such as image 3 shown). The cross-sectional area of the air inlet is adjusted through the middle rotating shaft of the adjustable air inlet flap 19. The supplied air exchanges heat with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com