Method for heating steel scrap and increasing smelting steel scrap ratio

A technology of steel scrap ratio and scrap steel, which is applied in the field of heating scrap steel and increasing the ratio of smelting scrap steel, can solve the problems of low smelting efficiency and low ratio of smelting scrap steel, and achieve the effects of reducing smelting cost, improving efficiency and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

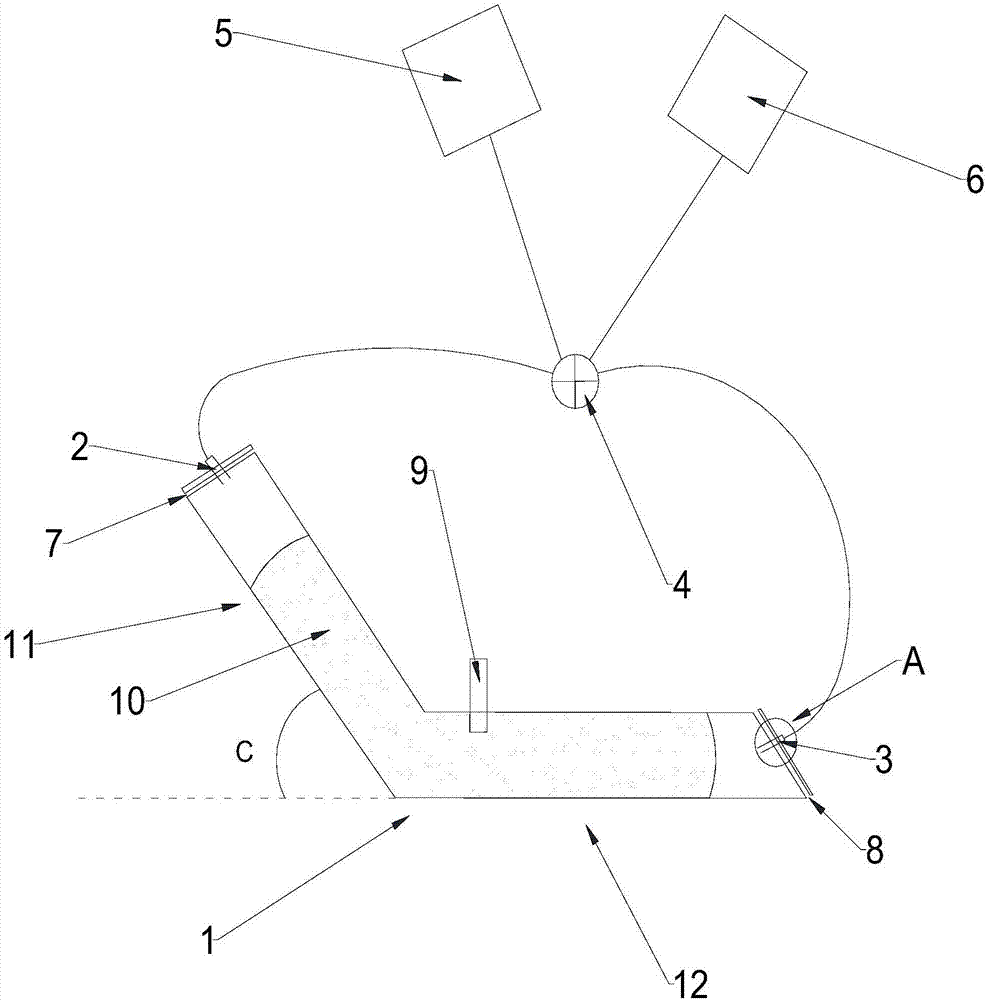

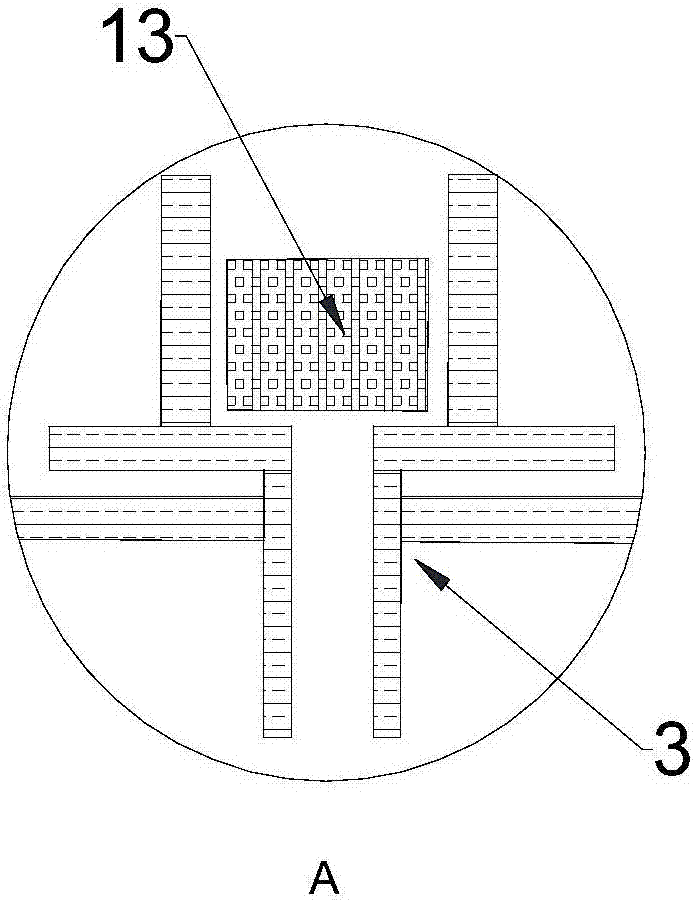

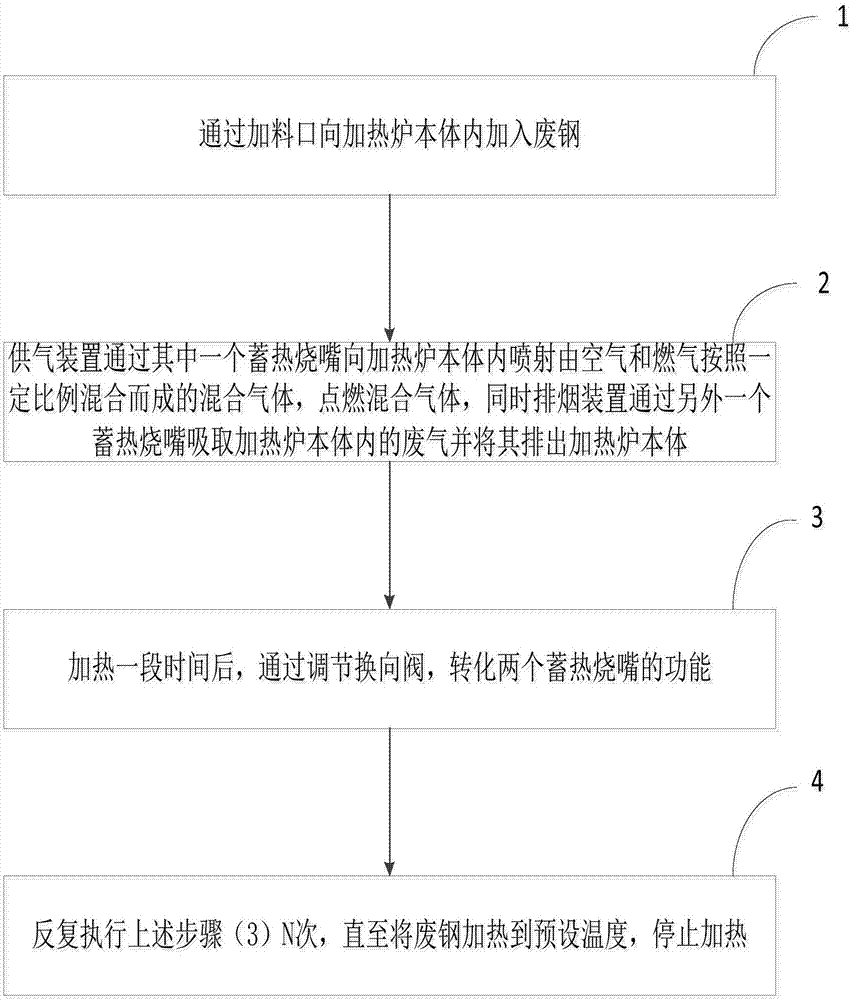

[0022] Such as figure 1 with 2 As shown, the scrap steel heating furnace includes a heating furnace body 1, a first regenerative burner 2, a second regenerative burner 3, a reversing valve 4, a temperature measuring instrument 9, a gas supply device 4 and a smoke exhaust device 5, and the heating furnace The body 1 includes an upper furnace body 11 and a lower furnace body 12. Both the upper furnace body 11 and the lower furnace body 12 have a cylindrical structure. The lower furnace body 12 is arranged horizontally, and the upper furnace body 11 is arranged obliquely. The bottom plate of the lower furnace body 12 is an included angle C, and the range of the included angle C is 0-120°. Specifically, the optimal value is obtained according to the experimental data. The lower end of the upper furnace body 11 communicates with one end of the lower furnace body 12, and further , in order to facilitate processing, the upper furnace body 11 and the lower furnace body 12 can be manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com