Preheating method and equipment for coated glass production

A coated glass and preheating technology, applied in the field of coated glass, can solve the problems of inability to effectively and accurately control the blowing temperature and moisture content, large fluctuations in product appearance and performance, and high environmental temperature and humidity requirements, so as to speed up the solvent volatilization rate. Uniformity, lowering curing temperature and curing oven length, and accelerating the uniformity of volatilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

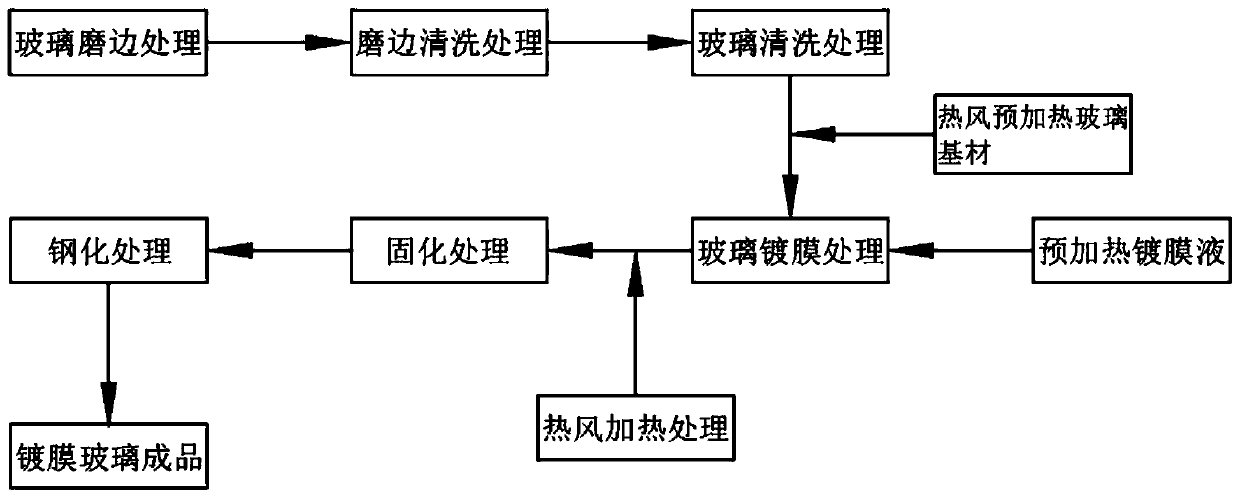

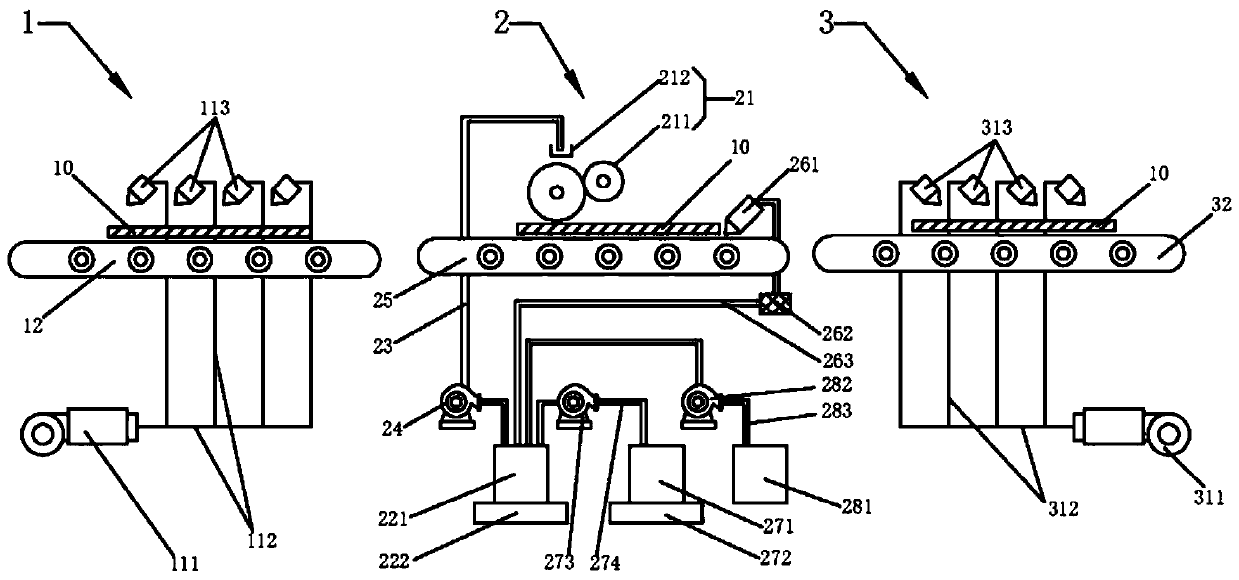

[0053] See attached figure 1 , 2 , a preheating method for coated glass production, comprising the steps of:

[0054] Step S1, preheating the glass substrate: using hot air to shower the surface of the glass substrate until the temperature of the glass substrate is 40°C;

[0055] Step S2, preheating the coating solution: raising the temperature of the coating solution to 30° C., and then coating the heated coating solution on the surface of the glass substrate preheated in step S1 to obtain a glass substrate 10 coated with the coating solution;

[0056] Step S3, post-heating treatment: use hot air to blow the glass substrate 10 coated with the coating solution in step S2, so that the temperature of the glass substrate 10 reaches 50° C., and prepare a preheated coated glass, ready for use and to be cured.

[0057] In the step S1, the first hot air device is used to shower the surface of the glass substrate; in the step S3, the second hot air device is used to shower the glass...

Embodiment 2

[0062] The difference between this embodiment and above-mentioned embodiment 1 is:

[0063] See attached figure 1 , 2 , a preheating method for coated glass production, comprising the steps of:

[0064] Step S1, preheating the glass substrate: blowing the surface of the glass substrate with hot air until the temperature of the glass substrate is 45°C;

[0065] Step S2, preheating the coating solution: raising the temperature of the coating solution to 32° C., and then coating the heated coating solution on the surface of the glass substrate preheated in step S1 to obtain a glass substrate 10 coated with the coating solution;

[0066] Step S3, post-heating treatment: use hot air to blow the glass substrate 10 coated with the coating solution in step S2, so that the temperature of the glass substrate 10 reaches 55° C., and prepare a preheated coated glass, ready for use and to be cured.

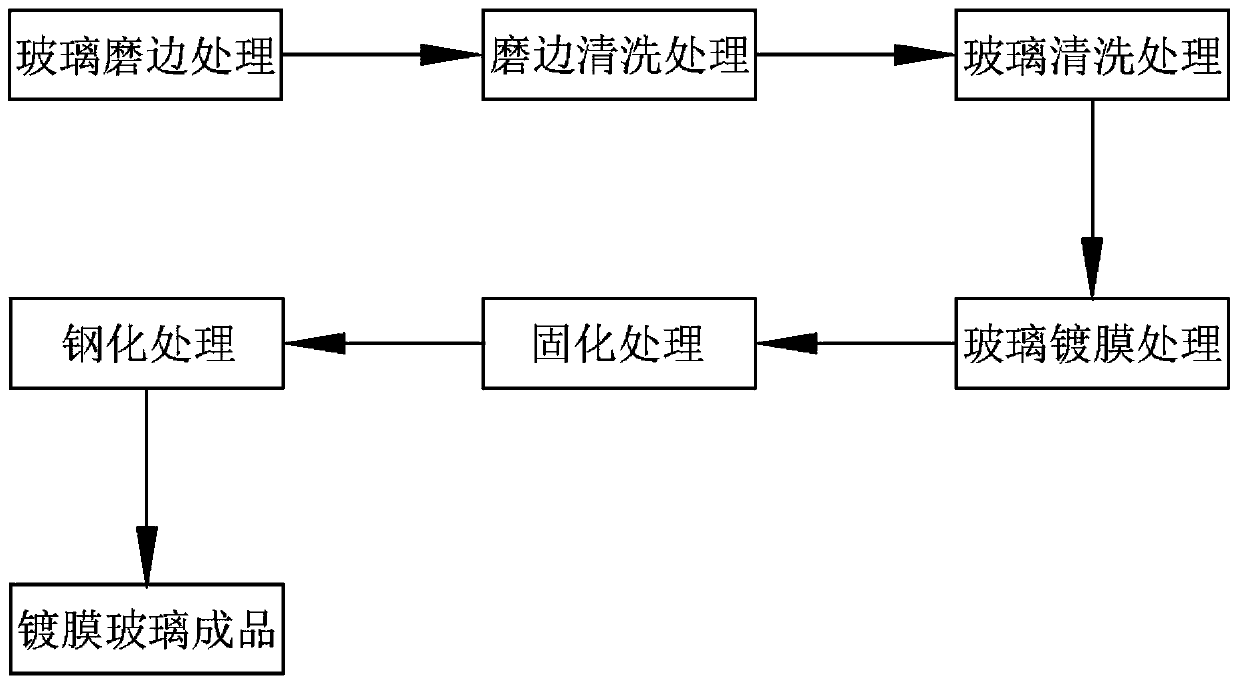

[0067] The coated glass process in this embodiment sequentially includes glass edging tr...

Embodiment 3

[0069] The difference between this embodiment and above-mentioned embodiment 1 is:

[0070] See attached figure 1 , 2 , a preheating method for coated glass production, comprising the steps of:

[0071] Step S1, preheating the glass substrate: using hot air to blow the surface of the glass substrate until the temperature of the glass substrate is 50°C;

[0072] Step S2, preheating the coating solution: raising the temperature of the coating solution to 35° C., and then coating the heated coating solution on the surface of the glass substrate preheated in step S1 to obtain a glass substrate 10 coated with the coating solution;

[0073] Step S3, post-heating treatment: use hot air to blow the glass substrate 10 coated with the coating solution in step S2, so that the temperature of the glass substrate 10 reaches 60°C, and prepare a preheated coated glass, which is ready for use and to be cured.

[0074] The coated glass process in this embodiment sequentially includes glass e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com