Fluidized bed winnowing and moisture controlling machine and new winnowing and moisture controlling process

A fluidized bed, a new process technology, applied in hearth furnaces, chemical instruments and methods, separating solids from solids with airflow, etc., can solve the problems that humidity adjustment and particle size classification cannot be realized at the same time, and achieve reduction Effects of fuel consumption, initial temperature increase, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

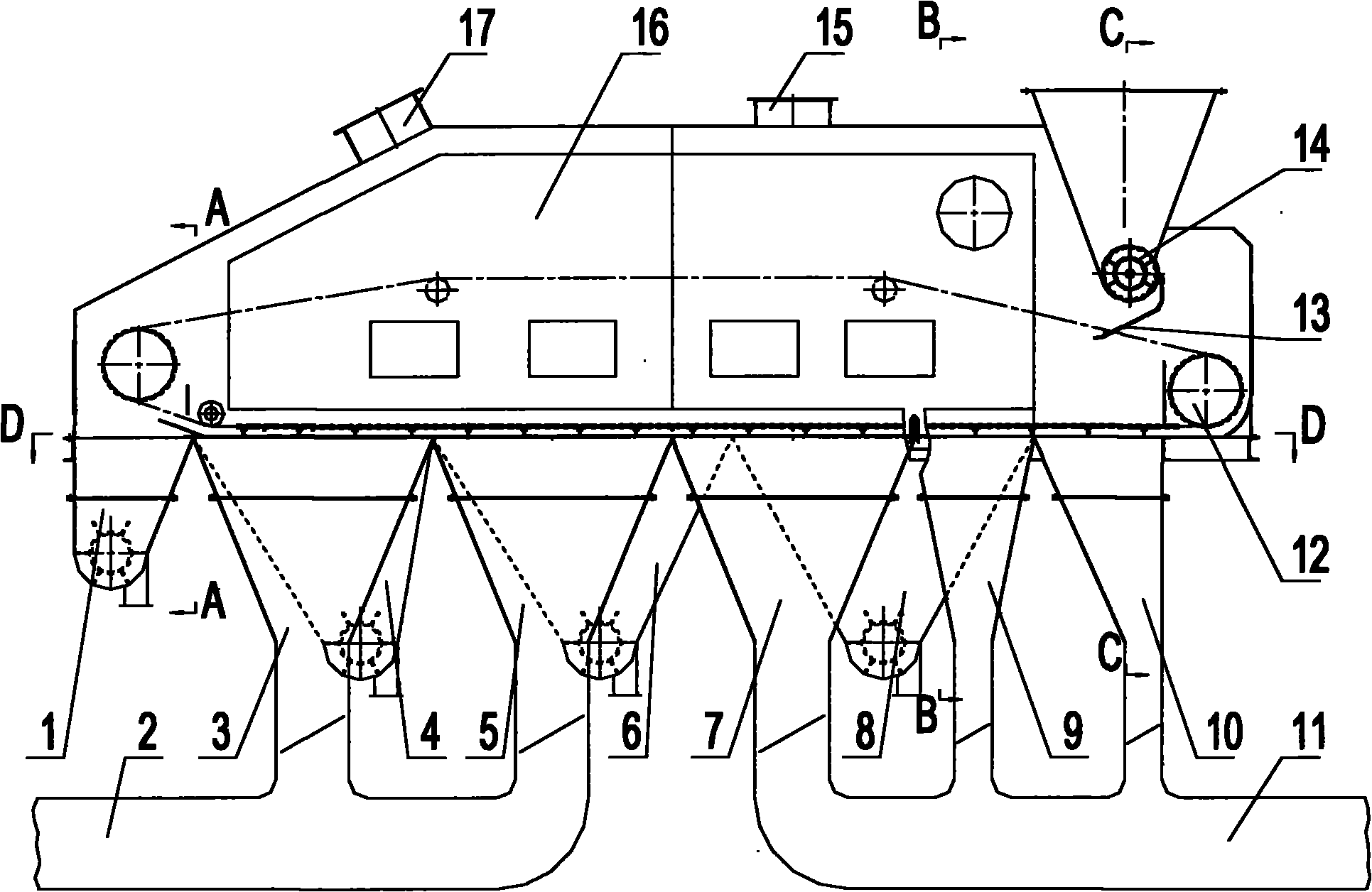

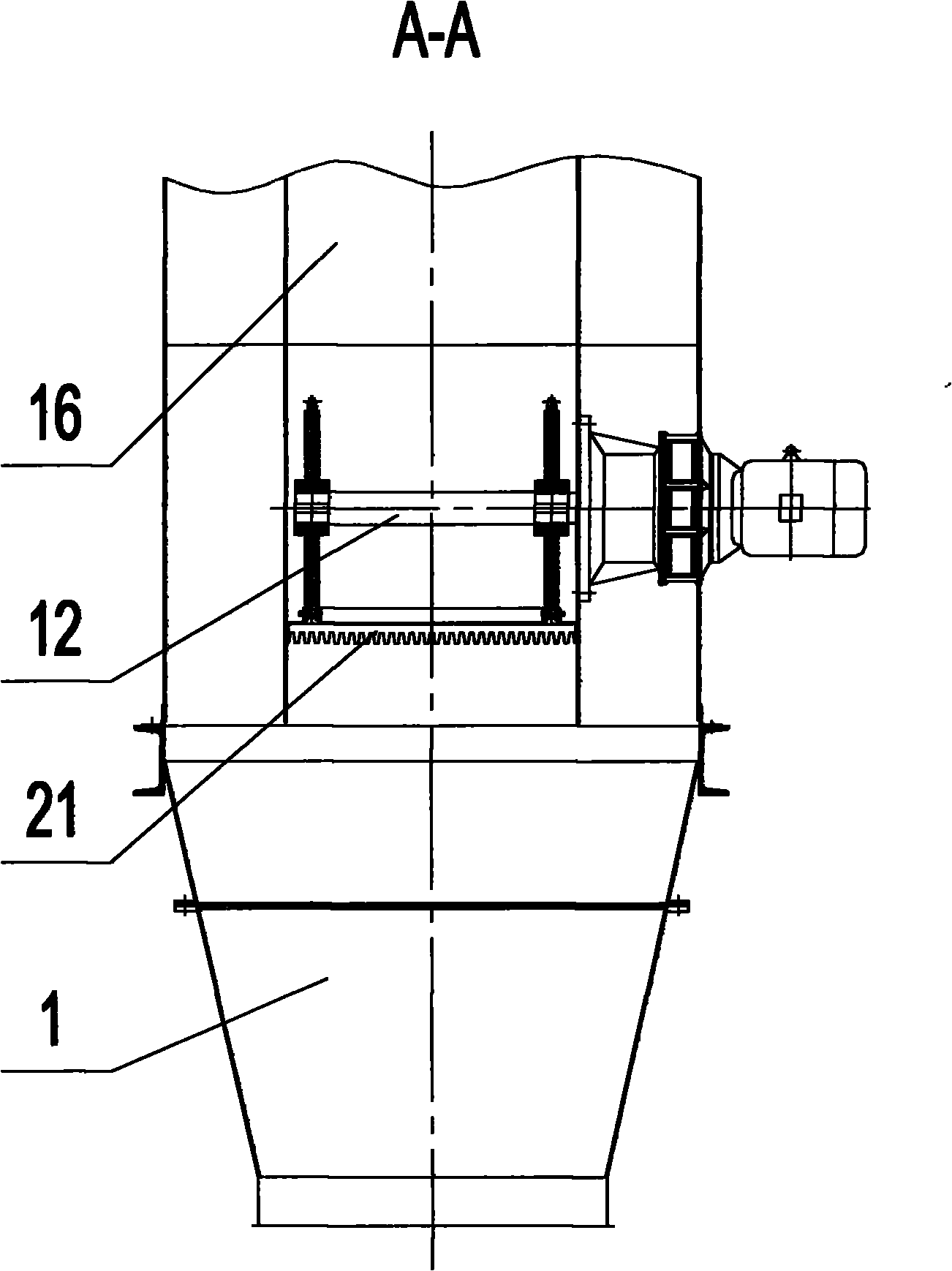

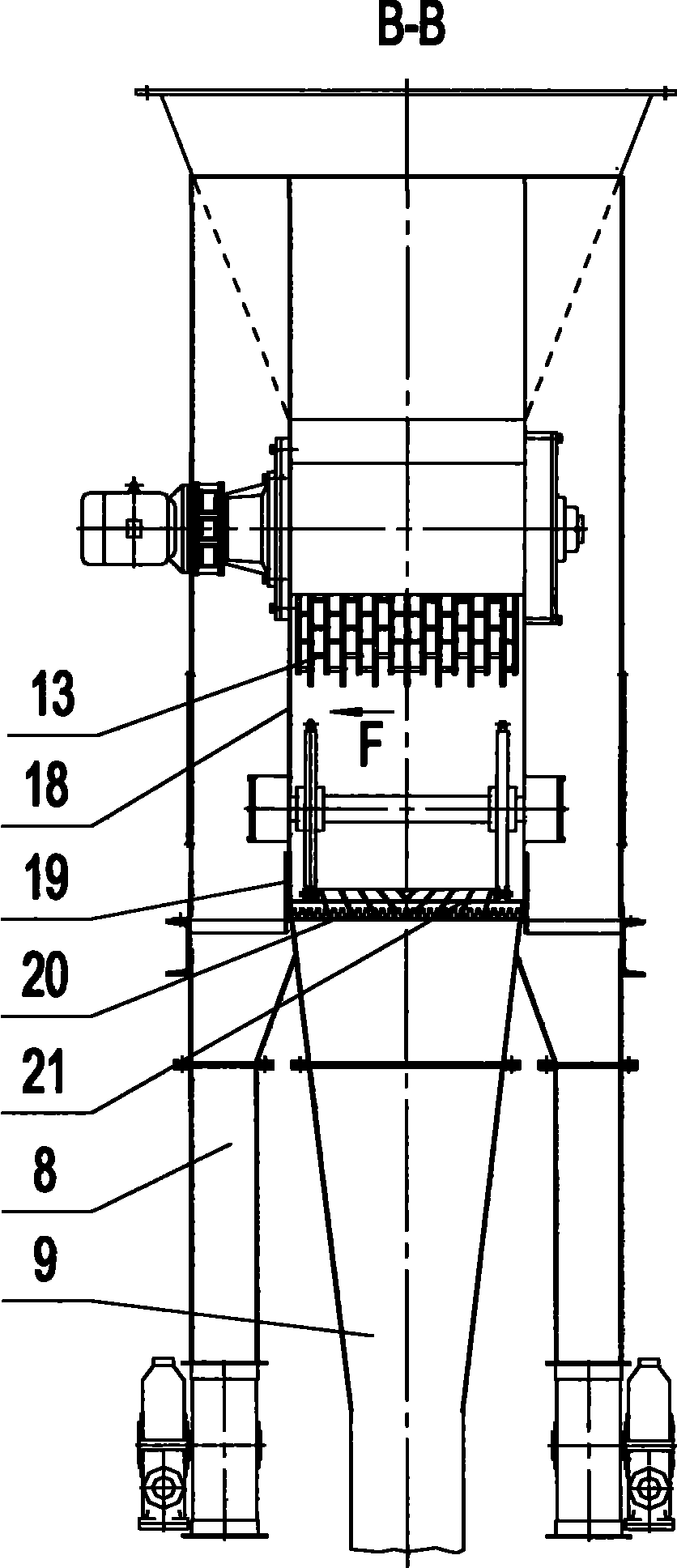

[0020] exist figure 1 , image 3 Among them, the bed body of the fluidized bed arranged in the closed casing (16) is divided into the bed body of the drying section and the bed body of the winnowing section, and the No. 1 air chamber (10) of the drying section is arranged under the bed of the drying section and the bed of the winnowing section respectively. , No. 2 air chamber (9) of drying section, No. 3 air chamber (7) of drying section and No. 1 air chamber (5) of wind selection section, No. 2 air chamber (3) of wind selection section, No. 2 air chamber (9) and Drying section No. 3 air chamber (7) is provided with drying section fine particle discharge pipe (8) on both sides, air selection section No. 1 air chamber (5) is equipped with air selection section No. 1 fine particle discharge pipe (6) on both sides, No. 2 fine particle discharge pipes (4) of the winnowing section are arranged on both sides of the No. 2 air chamber (3), and a coarse particle discharge pipe (1) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com