Method for growing perovskite monocrystal with liquid-liquid two-phase method

A perovskite and single crystal technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of harsh growth conditions, complicated process, poor controllability, etc., and achieve rapid response, low condition requirements, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Prepare a solution containing halogenated compounds;

[0043] Put a magnetic stirring bar into a 100ml tall beaker, measure 35ml hydroiodic acid (HI) and 25ml hypophosphorous acid (H 3 PO 2 ), put it into a beaker, place the whole device on a hot stage, stir and heat, and set the temperature to 15°C, take freshly synthesized methyl iodide (CH 3 NH 3 I), join it. Methyl iodide (CH 3 NH 3 1) After all dissolved, continue to keep stirring for 5h to obtain a solution containing halides with a concentration of 0.833mol / L.

[0044] 2. Weigh the solution that provides the tin source;

[0045] With a clean small bottle, put it on the balance in the glove box, measure the stannous isooctanoate solution in the small bottle with a pipette gun, tighten it, and take it out for later use; The molar ratio of halide ions in the solution is 1:0.9.

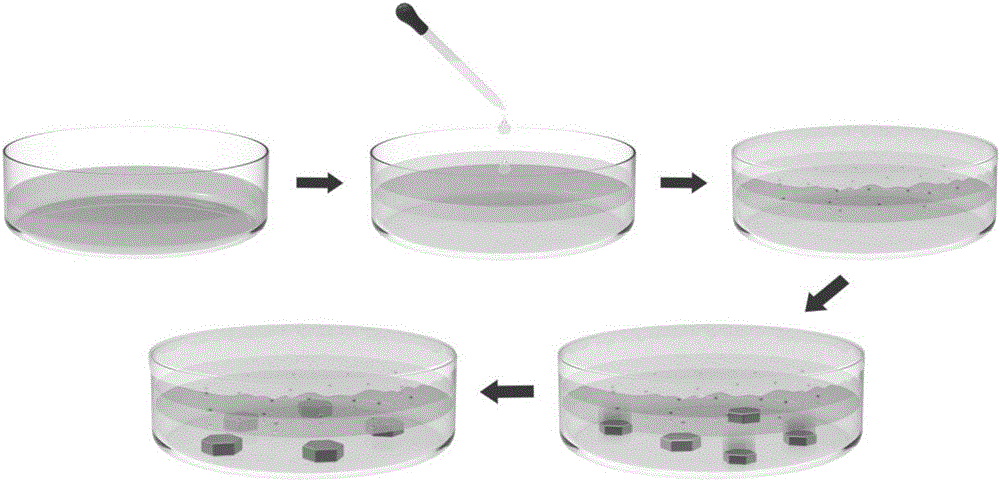

[0046] 3. Prepare liquid-liquid two-phase;

[0047] Add the halide-containing solution obtained in step 1 into a clean and dry ...

Embodiment 2

[0053] 1. Prepare a solution containing halogenated compounds;

[0054] Put a magnetic stirring bar into a 100ml tall beaker, measure 80ml hydroiodic acid (HI) and 10ml hypophosphorous acid (H 3 PO 2 ), put it into a beaker, place the whole device on a hot stage, stir and heat, set the temperature to 100°C, weigh 4.77g of freshly synthesized methyl iodide (CH 3 NH 3 I), join it. Methyl iodide (CH 3 NH 3 1) After all dissolved, continue to keep stirring for 8h to obtain a solution containing halides. (concentration is 0.43M)

[0055] 2. Weigh the solution that provides the tin source;

[0056] With a clean small bottle, put it on the balance in the glove box, measure 12.15g stannous isooctanoate solvent in the small bottle with a pipette gun, tighten it, and take it out for later use;

[0057] 3. Prepare liquid-liquid two-phase;

[0058] Add the halide-containing solution obtained in step 1 into a clean and dry crystallization dish, draw up the solvent with a pipette, ...

Embodiment 3

[0064] 1. Prepare a solution containing halogenated compounds;

[0065] Put a magnetic stirring bar into a 100ml tall beaker, measure 25ml hydroiodic acid (HI) and 5ml hypophosphorous acid (H 3 PO 2 ), put it into a beaker, place the whole device on a hot stage, stir and heat, set the temperature to 80°C, weigh 3.18g of freshly synthesized methyl iodide (CH 3 NH 3 I), join them. Methyl iodide (CH 3 NH 3 1) After all dissolved, continue to keep stirring for 5h to obtain a solution containing halides. (concentration is 0.67M)

[0066] 2. Weigh the solution that provides the tin source;

[0067] With a clean small bottle, put it on the balance in the glove box, measure 6.396g stannous isooctanoate solvent in the small bottle with a pipette gun, tighten it, and take it out for later use;

[0068] 3. Prepare liquid-liquid two-phase;

[0069] Add the halide-containing solution obtained in step 1 into a clean and dry crystallization dish, draw up the solvent with a pipette, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com