Massive thermal shock testing device of hyperthermal material

A test device and thermal shock technology, which is applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems of large dispersion of brittle materials, great influence of environmental factors, and impracticability of test pieces, so as to achieve accurate impact performance testing and environmental factors. Small influence, avoiding the effect of initial temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

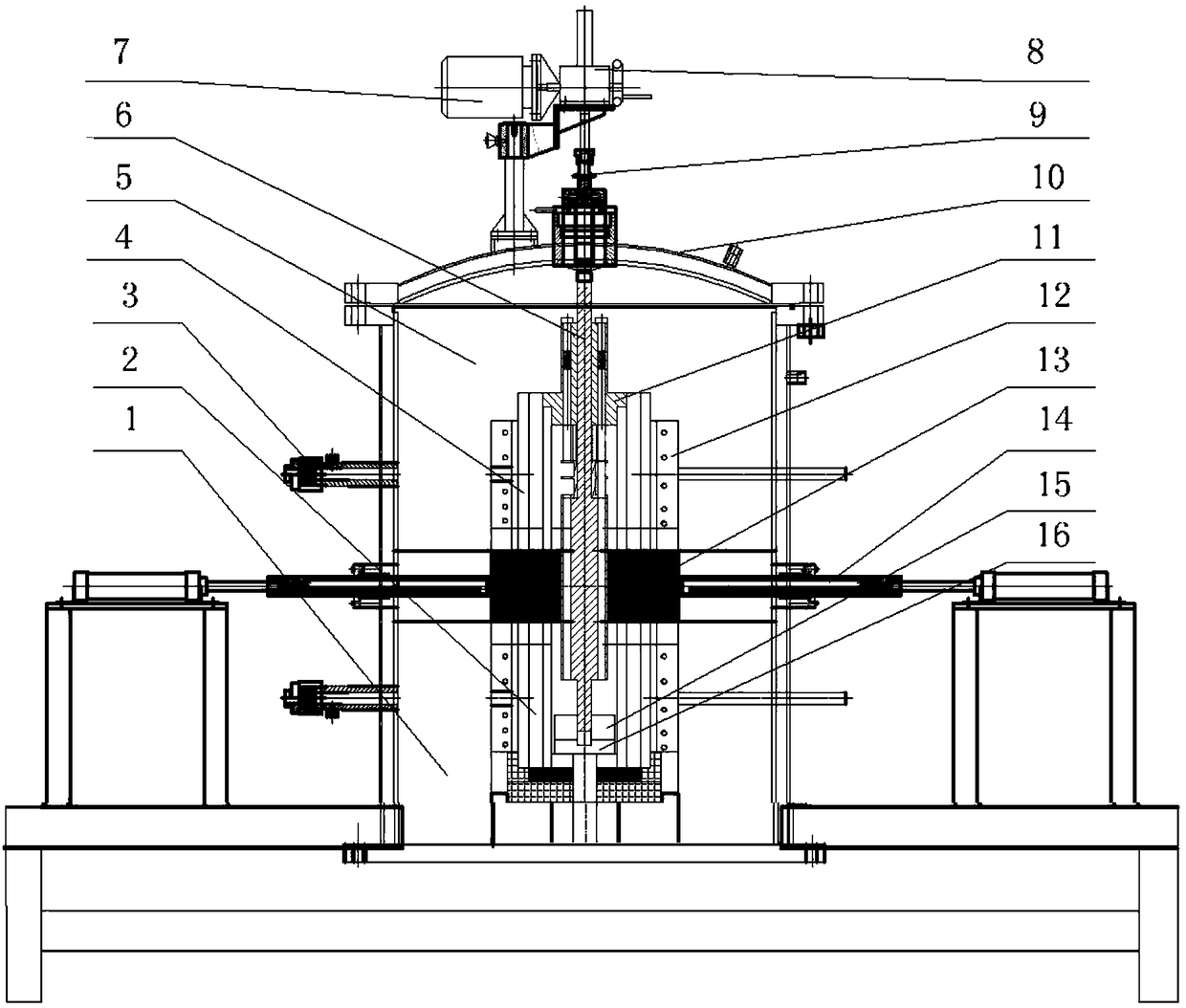

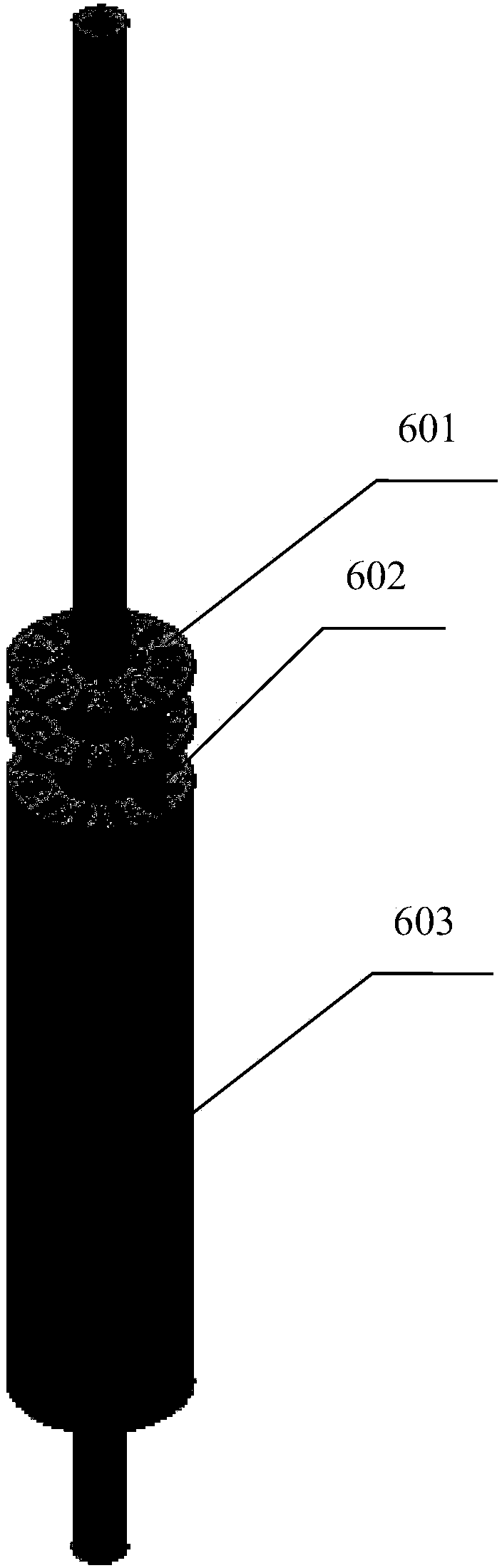

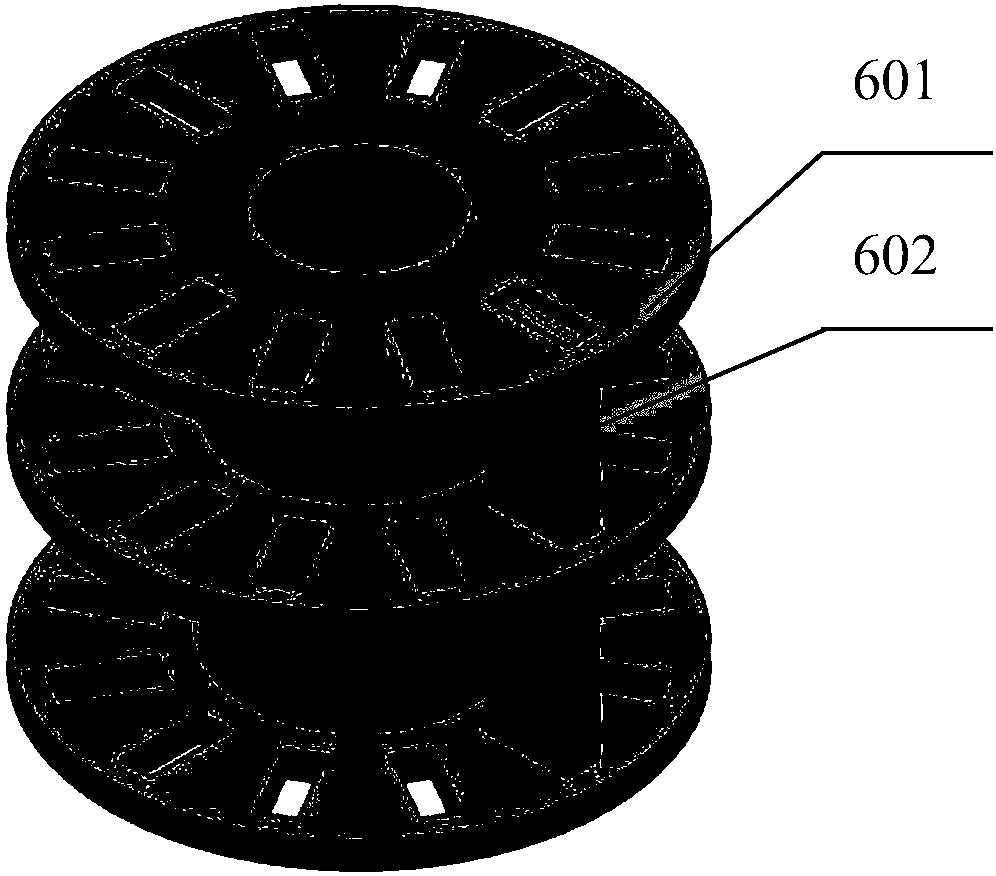

[0025] like figure 1 As shown, the present invention includes two upper environmental modules 5 and lower environmental modules 1 overlapping from top to bottom, each environmental module is provided with an upper heating furnace 4 and a lower heating furnace 2 correspondingly, and the upper environmental module 5 and the lower environmental module 1 The airtight partitions 13 controlled to open and close by the pneumatic push rod 14 are isolated; the top of the upper heating furnace 4 is equipped with a test piece preloading mechanism 11, which includes a fixing frame 114, and the inside of the fixing frame 114 is from top to bottom. Screws 111, springs 112 and push fingers 113 are respectively installed below. A test piece introduction mechanism 6 is installed between the upper heating furnace 4 and the lower heating furnace 2, the upper end of which is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com