Active heating system for oil pipeline

a technology for heating systems and oil pipelines, applied in the field of oil pipelines, to achieve the effect of reducing the time to initiate a start up in the pipeline, reducing the energy expenditure, and shortening the priod of tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

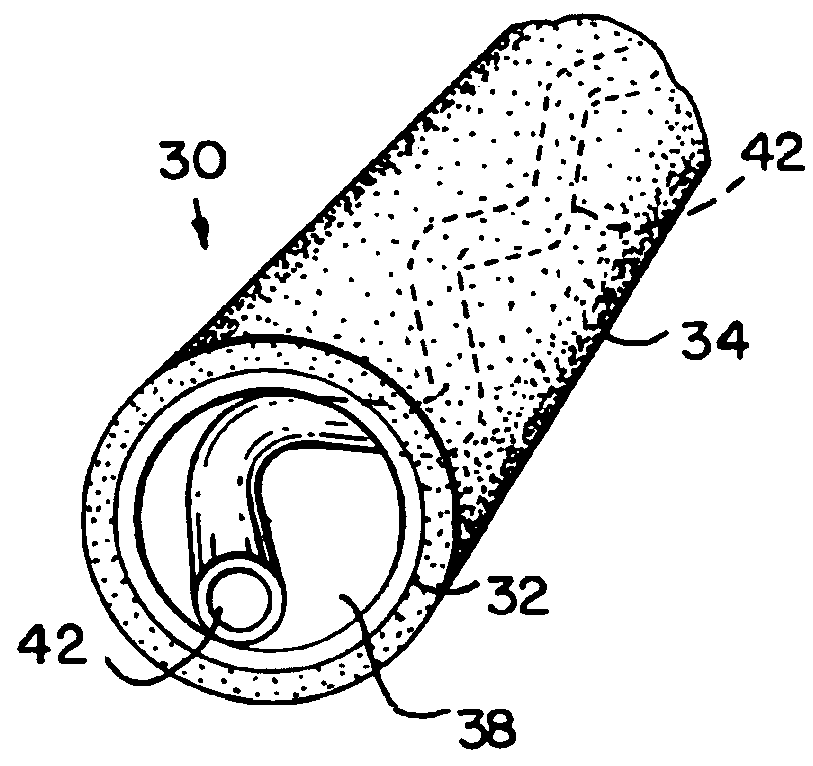

[0030]Turning to the embodiment of the invention disclosed in FIGS. 3 and 4, the proposed pipeline 30 includes an outer main pipeline 32 which may be insulated, as at the layer 34, or may not be insulated, and may be buried beneath the subsea surface, which could insulate it against heat loss outward. The pipeline may be rigid or flexible, as is known.

[0031]An elongate tube 36 passes through and along the main pipeline. It may be inserted during the pipeline fabrication process. The tube 36 may be inserted loosely in the pipe 32 and not be attached to the internal surface of the main pipeline. Alternatively, the tube may be affixed to the pipeline 32. It would be preferably attached at the ends of the pipeline. In interior surface 38, the tube may extend straight through the pipeline, or may have another shape therein, e.g., in a helix 42, as shown in FIG. 5. The helix may be normally sprung outward to rest on the pipeline interior surface or not, as selected.

[0032]In FIG. 3, the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com