Washing machine driving device, washing machine having the same, and washing machine driving method

A technology for driving devices and washing machines, which is applied to the control devices of washing machines, washing devices, and other washing machines, etc., which can solve problems such as slow dynamic response, low torque characteristics, and a brushless DC motor drive method that has not yet been proposed, so as to improve the operating rate , The overall power consumption is minimized, and the effect of reducing the overall washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

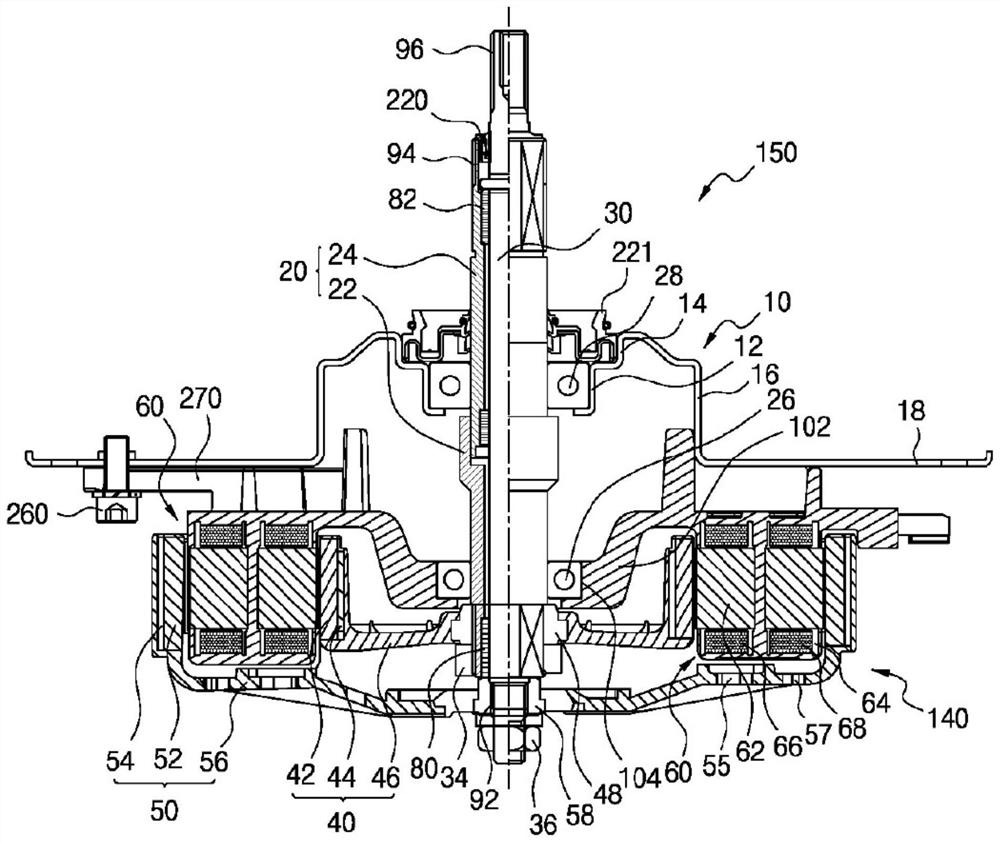

[0198] refer to Figure 9 The rotation speed timing diagram for forming the washing water flow in the opposite direction, in the method for forming the washing water flow in the opposite direction in Embodiment 1 of the present invention, basically, the pulsator 130 moves in one direction, for example, in the forward direction, that is, in the clockwise direction ( CW) rotary drive, within a preset time, after maintaining the motor ON time (ON TIME), there is a prescribed stop time (OFF TIME) for direction switching.

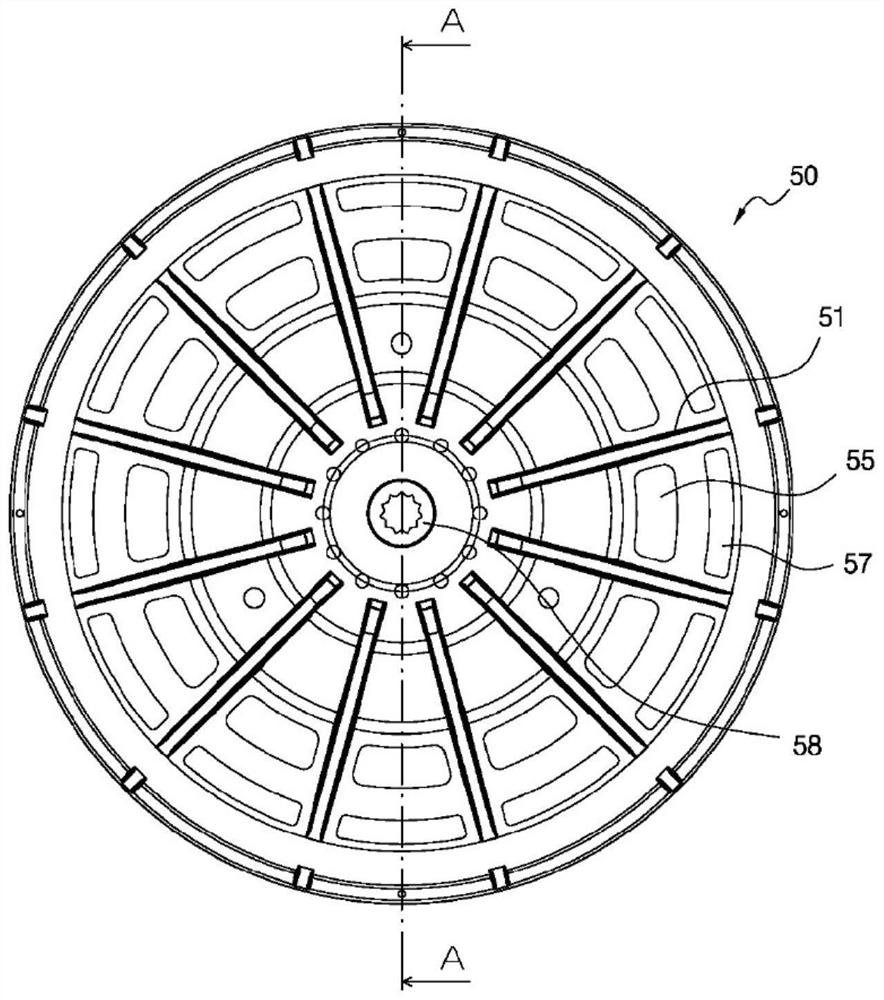

[0199] Figure 9 Graph P shows the rotational speed of the outer rotor 50 for driving the pulsator 130, and the graph S shows the rotational speed of the inner rotor 40 for driving the spin basket.

[0200] After that, the pulsator 130 is rotated in another direction, for example, in the reverse direction, that is, counterclockwise (CCW). In the preset time, after maintaining the motor ON time (ON TIME), there is a function for direction switching. The specifi...

Embodiment 2

[0213] refer to Figure 10 , the washing water flow forming method of the opposite direction of embodiment 2 and Figure 9 Example 1 shown is similar.

[0214] In Embodiment 1, the outer rotor 50 was overshoot-driven from 160 RPM to 200 RPM and then stopped before the initial drive of the motor ON TIME (ON TIME), but in the second embodiment, no overshoot drive was performed. In order to generate eddy current, drive the washing tub 120 in the opposite direction to the rotation direction of the pulsator 130 within 1 second during the initial drive of the motor ON time (ON TIME) and before the end, to increase the vortex one more time. The way the number of occurrences changes the drive method.

[0215] That is, in Embodiment 2, with the driving of the outer rotor 50, the pulsator 130 is rotated in the forward direction at 160 RPM, and at the same time, the inner rotor 40 is driven in the reverse direction for 1.2 seconds, so that the washing tank 120 is rotated in the reverse...

Embodiment 3

[0223] refer to Figure 11 , the formation method of the reverse direction washing water flow in Example 3 is generally similar to that in Example 1 and Example 2.

[0224] The difference between Example 1 and Example 2 and Example 3 is as follows: when the motor ON time (ON TIME) is initially driven and before the end, instead of the outer rotor 50, the overshoot is driven from 160 RPM to 200 RPM, and the rotational speed is increased to 200 RPM. 160RPM to drive the rotational speed and driving torque of the pulsator 130 .

[0225] In addition, in the middle part of the motor ON TIME (ON TIME), the speed adjustment section Pd in which the rotation speed of the outer rotor 50 is lowered from 160 RPM to 120 RPM is increased by inserting, and a strong washing water flow such as a large wave can be generated.

[0226] In particular, in Example 3, the motor ON time (ON TIME) is shorter than that of Example 1 and Example 2, and the OFF time (OFF TIME) is longer. When the number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com