Coating device and coating method

A coating device and coating technology, which is applied to the surface coating liquid device, measuring device, coating, etc., can solve the problems of low operating rate of the device, high adjustment frequency, unstable coating process, etc., and achieve change Effects of drying time, stable quality, and excellent operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

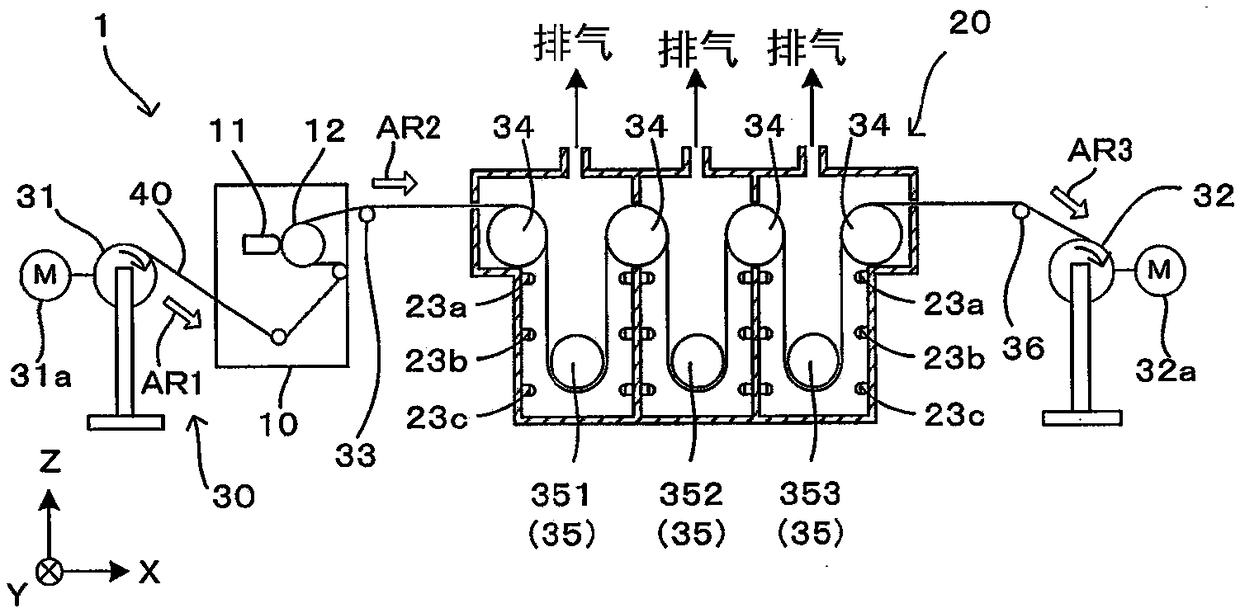

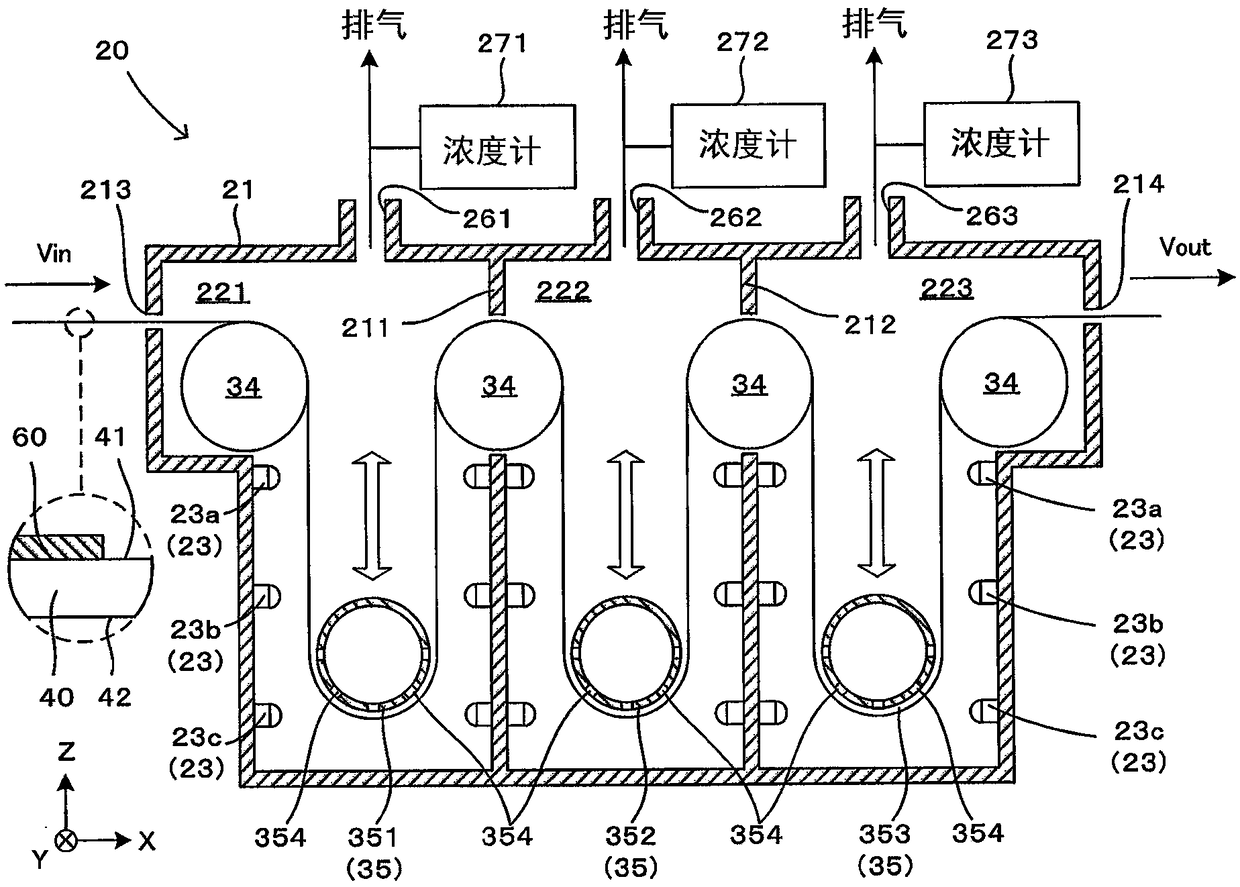

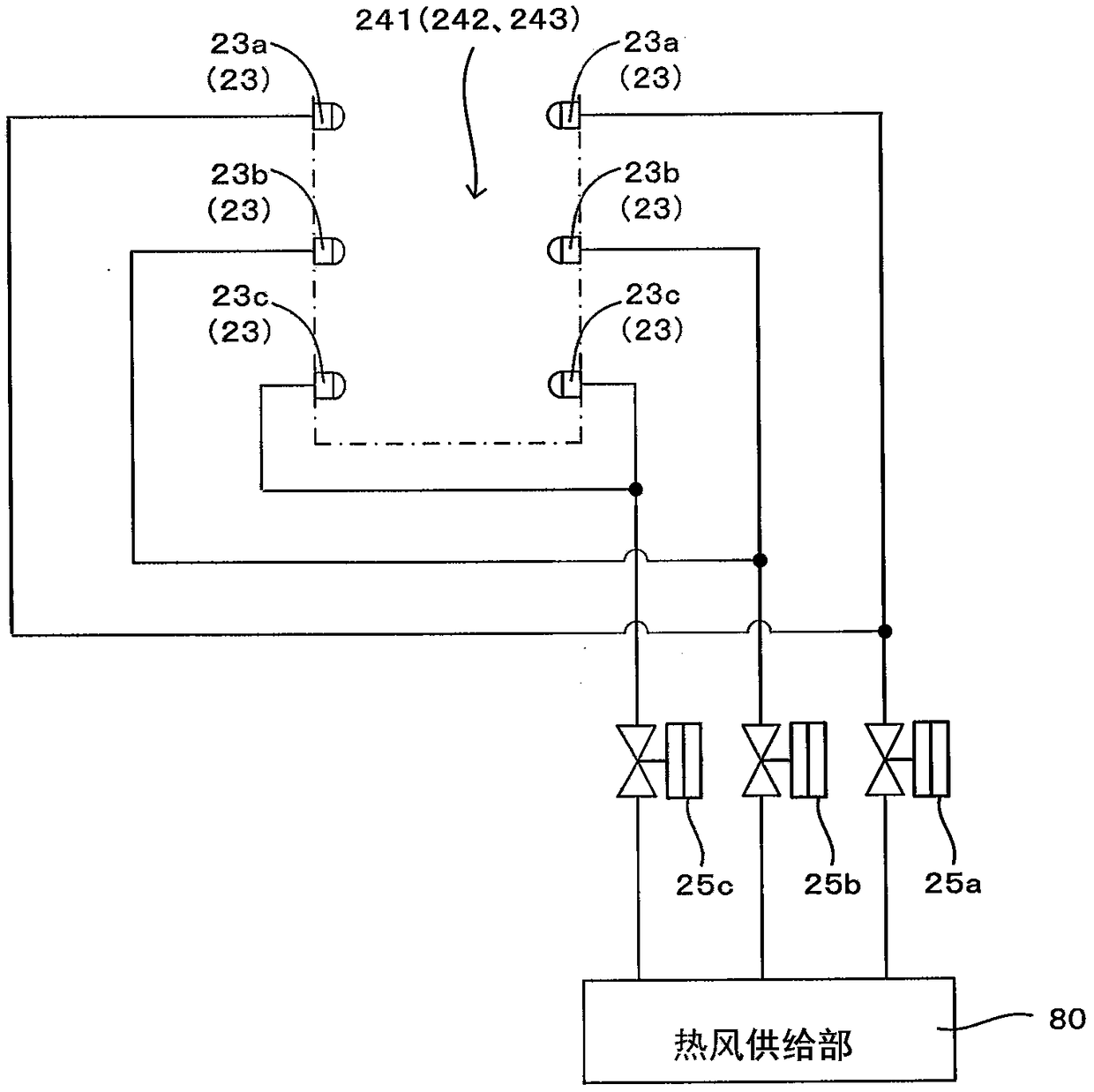

[0035] figure 1 It is a figure which shows the whole structure of the coating apparatus which concerns on one Embodiment of this invention. It should be noted that, in figure 1 In each of the following drawings, in order to clarify the directional relationship, an XYZ rectangular coordinate system is shown in which the Z-axis direction is the vertical direction and the XY plane is the horizontal plane. In addition, in figure 1 In the subsequent drawings, for ease of understanding, the size or quantity of each part is exaggerated or simplified as required.

[0036] The coating device 1 conveys a strip-shaped base material along a predetermined conveying direction, and at the same time discharges a coating liquid containing an active material material on the surface of the base material, thereby coating a coating film on the base material, and by The drying section dries the coated film to manufacture electrodes for lithium-ion secondary batteries. The coating apparatus 1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com