Colorful ultraviolet (UV) light solidifying paint

A light-curing coating and color technology, applied in the field of coatings, can solve the problems of coating performance degradation and environmental protection of UV coatings, and achieve the effects of easy construction, large promotion and application value, and good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

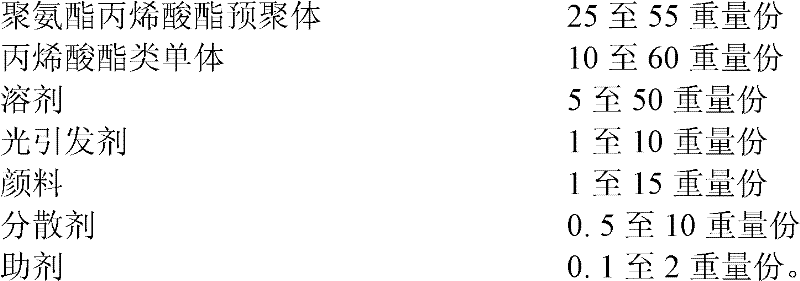

Method used

Image

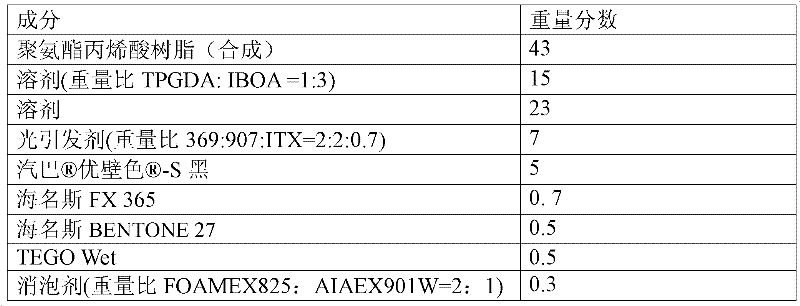

Examples

Embodiment 1

[0031] The specific implementation steps are as follows:

[0032] (1) Disperse the resin, monomer, part of the defoamer (accounting for 20% to 80% of the total amount), and the thixotropic agent with a high-speed disperser with a rotating speed of 1200 rpm for 15 minutes;

[0033] (2) Toner or color paste, wetting and dispersing agent, part of defoamer (20% to 40% of the total amount), and part of the solvent (5% to 50% of the total amount of solvent) are ground on a three-roller machine to Scatter until the system is even and fine, and then pass through a 300-mesh net;

[0034] (3) The solid photoinitiator is mixed in proportion and dissolved in the solvent that has been mixed in proportion;

[0035] (4) Stir the product obtained in step 1, step 2 and step 3 with solvent, leveling agent, remaining defoamer, solvent, etc. with a disperser whose rotation speed is 600 rpm;

[0036] (5) Cross a 300-mesh filter screen to obtain UV colored paint.

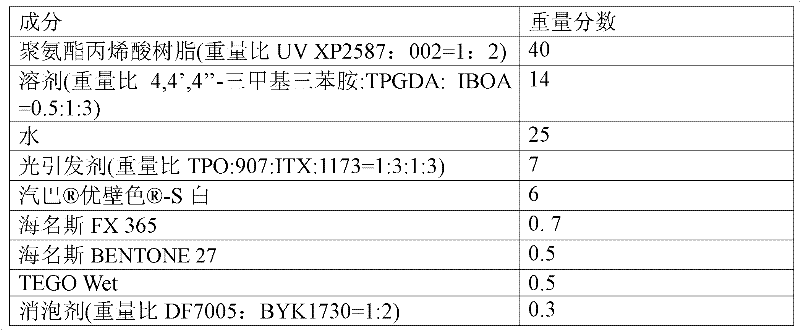

Embodiment 2

[0038] Element

[0039] X-fast yellow

[0040] The specific implementation method is the same as the first embodiment.

Embodiment 3

[0042] Element

[0043] The specific implementation method is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com