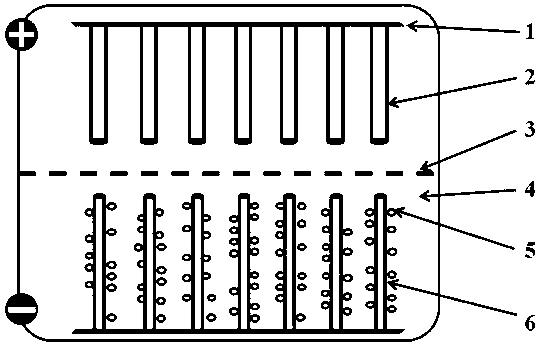

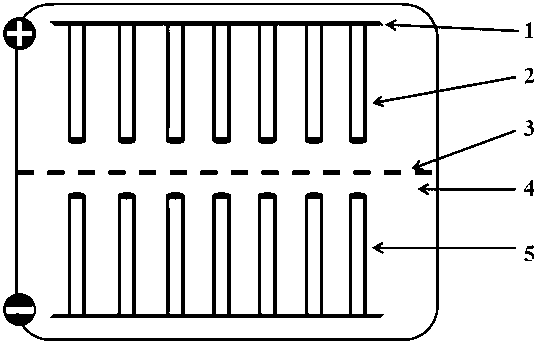

Mixed type electrochemical capacitor

An electrochemical and capacitor technology, which is applied in the field of hybrid electrochemical capacitors, can solve the problems of low specific capacitance, poor cycle performance and conductivity, and affect the energy density of devices, so as to achieve high practical value, high power density and cycle stability , the effect of alleviating energy shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Preparation of aligned carbon nanotube arrays:

[0052] Put the Al foil into the tube furnace, under H 2 Under the protection of Ar mixed gas (volume ratio 1:9), the temperature was raised to 650 °C, and the ethanol solution of ferrocene (concentration: 0.075 mol / L) was passed through, and the aligned carbon nanotube arrays were directly grown on the Surface of Al foil.

[0053] (2) Preparation of positive pole piece:

[0054] Put the aligned carbon nanotube array obtained in step (1) as a working electrode into a mixed solution of aniline and sulfuric acid, the concentrations of aniline and sulfuric acid were 0.1 mol / L and 1 mol / L, respectively, and a platinum sheet was used as an auxiliary electrode. The Ag / AgCl electrode was used as the reference electrode. Electrochemical cyclic voltammetry was adopted. The voltage between the working electrode and the auxiliary electrode was -0.2~0.8 V. The scan rate was 50 mV / s and the number of cycles was 30 times. Perform...

Embodiment 2

[0060] (1) Preparation of aligned carbon nanotube arrays:

[0061] Put the Ti foil into a tube furnace at H 2 / Ar mixed gas (volume ratio 1:9), the temperature was raised to 800 °C, and the ethanol solution of ferrocene (0.05 mol / L) was passed through, and the aligned carbon nanotube array was directly grown on the The surface of the Ti foil.

[0062] (2) Preparation of positive pole piece:

[0063] The aligned carbon nanotube array obtained in step (1) was used as a working electrode and placed in a sodium sulfate solution with a concentration of 0.1 mol / L, a platinum sheet was used as an auxiliary electrode, and an Ag / AgCl electrode was used as a reference electrode. Current method, the current value is 0.1 A / cm 2 , the reaction cut-off voltage is 1.0 V, for Mn 2+ Manganese oxide is prepared by ion oxidation, and the manganese oxide is deposited on the surface of the aligned carbon nanotubes, then washed and dried, and the content of the manganese oxide is 47% by weight....

Embodiment 3

[0069] (1) Preparation of aligned carbon nanotube arrays:

[0070] Put Ni foam into the tube furnace, under H 2 Under the protection of Ar mixed gas (volume ratio 1:9), the temperature was raised to 800 °C, and the ethanol solution of ferrocene (concentration: 0.08 mol / L) was introduced, and the aligned carbon nanotube arrays were directly grown on the The surface of Ni foam.

[0071] (2) Preparation of positive pole piece:

[0072] Put the aligned carbon nanotube array obtained in step (1) as a working electrode into potassium permanganate with a concentration of 0.1 mol / L, heat to 70 °C, and react for 2 h to deposit manganese oxide on the aligned carbon nanotubes. The surface is then washed and dried, and the content of manganese oxide is 66% by weight.

[0073] (3) Preparation of negative pole piece:

[0074] Put the aligned carbon nanotube array obtained in step (1) as the working electrode into the mixed solution of pyrrole and sodium nitrate, the concentrations of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com