Preparation method for rubber/keramite nano-tube nano-composite material

A technology of halloysite nanotubes and nanocomposites, which is applied in the field of preparation of rubber and/or halloysite nanotube nanocomposites, and can solve the problem of poor compatibility between halloysite nanotubes and rubber matrix and the difficulty in obtaining the performance of composite materials Significantly improve the difficulty of forming nano-scale dispersion and other problems, achieve the effects of simplifying organic modification and nano-composite process, reducing the shortage of carbon black raw materials, and excellent toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

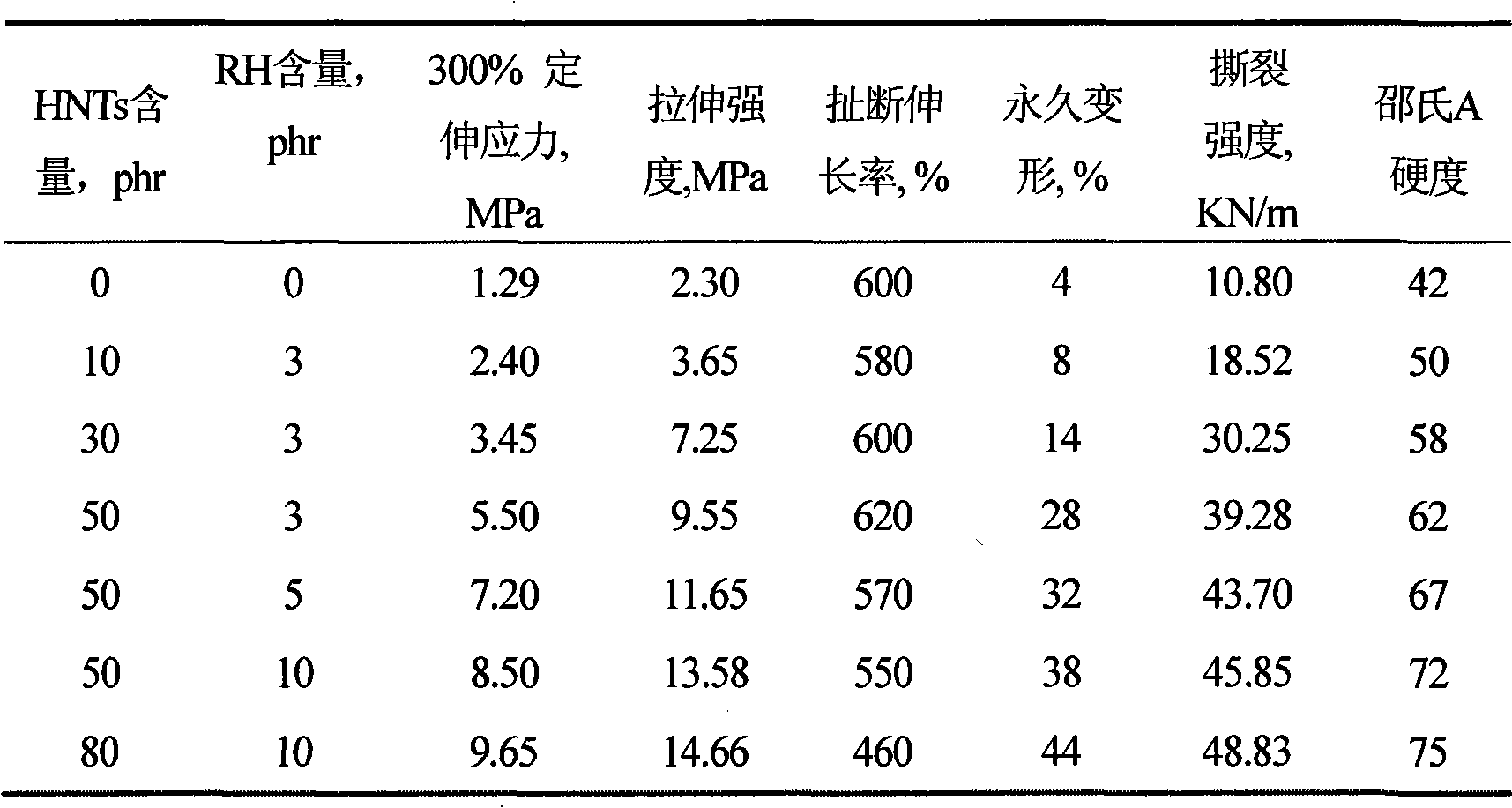

[0025] Styrene-butadiene rubber (SBR) and halloysite nanotubes (HNTs) were selected, and complexes of resorcinol and hexamethylenetetramine (RH) were used as modifiers. Formula (mass ratio): SBR 100, HNTs 0-80, RH 0-10, stearic acid 2, zinc oxide 5, accelerator CZ 1.5, accelerator DM 0.5, antioxidant 4010NA 1.5, sulfur 1.5. Mixing is carried out on a two-roll mill, first adding HNTs and RH, then adding other compounding agents, and finally adding sulfur, and then vulcanizing on a flat vulcanizing machine, the vulcanizing temperature is 150°C, and the vulcanization time is determined according to the positive vulcanization time measured by the vulcanization meter. .

[0026] Table 1 lists the mechanical properties of SBR / HNTs / RH nanocomposite vulcanizates with different HNTs contents and different RH contents. It can be seen from the table that with the increase of the amount of HNTs and RH, the modulus stress, tensile strength, tear strength and hardness of SBR / HNTs / RH vulcan...

Embodiment 2

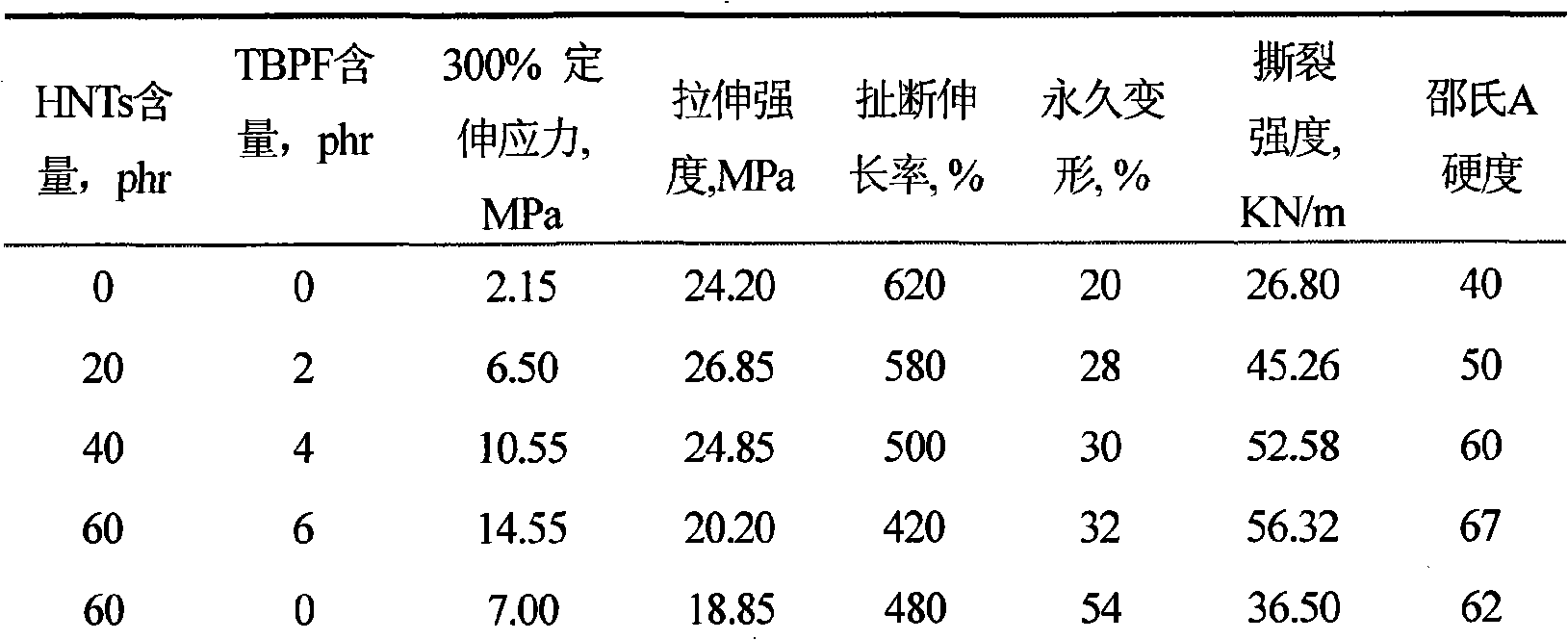

[0031] Natural rubber (NR) and butadiene rubber (BR) are used together, HNTs is used as nano filler, and p-tert-butylphenolic resin (TBPF) is used as modifier. Formula (mass ratio): NR 80, BR 20, HNTs 0-60, TBPF 0-6, stearic acid 2, zinc oxide 5, accelerator CZ 1.5, accelerator DM 0.5, antioxidant 4010NA 1.5, sulfur 1.5. Mixing on the open mill, first add NR and BR for blending, then add HNTs and TBPF, then add other compounding ingredients, and finally add sulfur to obtain a mixed rubber. The mixed rubber is vulcanized on a flat vulcanizer, the vulcanization temperature is 143°C, and the vulcanization time is determined according to the positive vulcanization time measured by the vulcanizer.

[0032] The mechanical properties of NR / BR / HNTs / TBPF nanocomposite vulcanizates are shown in Table 2 (NR / BR mass ratio 80 / 20). It can be seen from the table that with the increase of the amount of HNTs and TBPF, the modulus, tear strength and hardness of NR / BR / HNTs / TBPF vulcanizate all ...

Embodiment 4

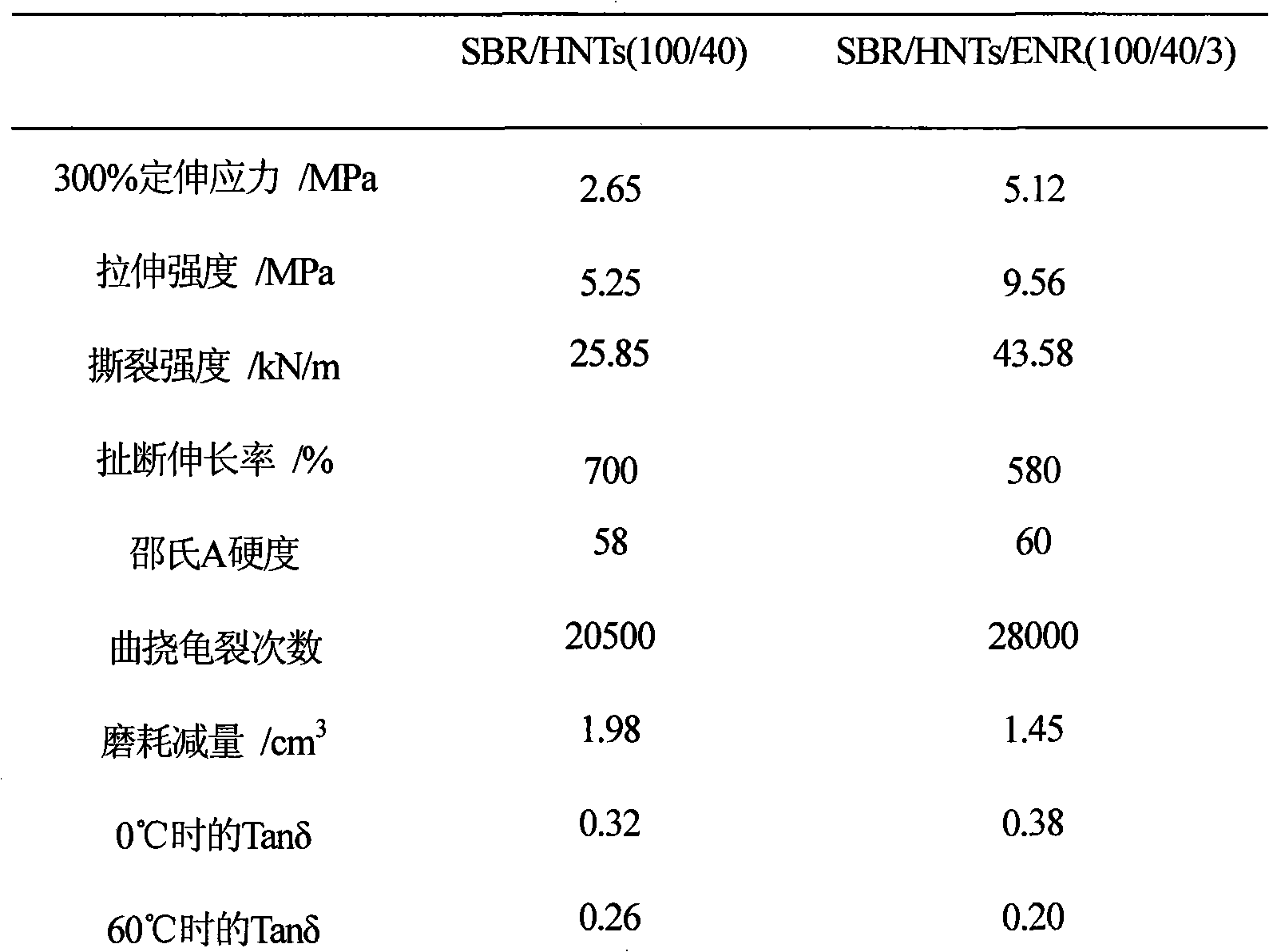

[0042] Styrene-butadiene rubber and halloysite nanotubes (SBR / HNTs) were selected, and zinc methacrylate (ZDMA) was used as a modifier. Formula (mass ratio): SBR 100, HNTs 0-100, ZDMA 0-20, stearic acid 2, zinc oxide 5, accelerator CZ 1.5, dicumyl peroxide (DCP) 1, antioxidant 4010NA 1.5, sulfur 1.5. Mixing is carried out on an open mill, first adding HNTs and ZDMA, then adding other compounding agents, and finally adding sulfur and DCP, and then vulcanizing on a flat vulcanizing machine, the vulcanization temperature is 160 ° C, and the vulcanization time is according to the positive vulcanization time measured by the vulcanization meter.

[0043] Table 4 lists the mechanical properties of SBR / HNTs / ZDMA nanocomposites. It can be seen from the table that with the increase of ZDMA content, the mechanical properties of SBR / HNTs / ZDMA nanocomposites show a significant improvement trend. The 300% modulus stress, tensile strength, tear strength, elongation at break and Shore A har...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com