Process for preparing active carbon by adding husks into chemical sludge

A technology for preparing activated carbon and chemical sludge, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as secondary pollution, endangering the ecological environment, occupying farmland, etc., and achieve a good environment and social benefits, the effects of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take the residual sludge of a petrochemical plant with a mass moisture content of 75%, dry it at 120°C for 6 hours, weigh 1kg of dried sludge, add 5g of coconut shell in turn, grind until the average particle size is 0.71mm, and then add 0.5L to a concentration of 3mol / L potassium hydroxide activation solution; soak and activate at 90°C for 4h, stir at 150r / min while activating, and dry (dry at 120°C for 4h). Under the protection of 600°C (heating rate of 15°C / min) and nitrogen purge rate of 150mL / min, pyrolysis was carried out for 3h. Cool, wash with 1mol / L hydrochloric acid, and dry; then wash with water, and dry to obtain activated carbon. The measured specific surface area is: 441m 2 / g, the leaching concentration of heavy metals is shown in Table 1.

Embodiment 2

[0027] Take the residual sludge from a sewage treatment plant of a pesticide factory with a mass moisture content of 80%, dry it at 110°C for 8 hours, weigh 1kg of dried sludge, add 15g of apricot kernels in turn, grind until the average particle size is 0.50mm, and then add 1L concentration Potassium hydroxide and zinc chloride solutions of 3 mol / L; soak and activate at 85°C for 6h, stir at 100r / min while activating, and dry (dry at 110°C for 8h). Under the protection of 700°C (heating rate of 10°C / min) and helium purge rate of 100mL / min, pyrolysis was carried out for 2.5h. Cool, wash with 0.8mol / L hydrochloric acid, and dry; then wash with water, and dry to obtain activated carbon. The measured specific surface area is: 465m 2 / g, the leaching concentration of heavy metals is shown in Table 1.

Embodiment 3

[0029] Take the residual sludge of a sewage treatment plant of a pharmaceutical and chemical factory with a mass moisture content of 85%, dry it at 105°C for 24 hours, weigh 1kg of dried sludge, add 30g of peach pits in turn, grind until the average particle size is 0.15mm, and then add 2L Potassium sulfide solution with a concentration of 1mol / L; soak and activate at 75°C for 8h, and dry at 200r / min while activating (dry at 105°C for 24h). Under the protection of 800°C (heating rate of 20°C / min) and argon purge rate of 180mL / min, pyrolysis was carried out for 5h. Cool, wash with 1.5mol / L hydrochloric acid, and dry; then wash with water, and dry to obtain activated carbon. The measured specific surface area is: 510m 2 / g, the leaching concentration of heavy metals is shown in Table 1.

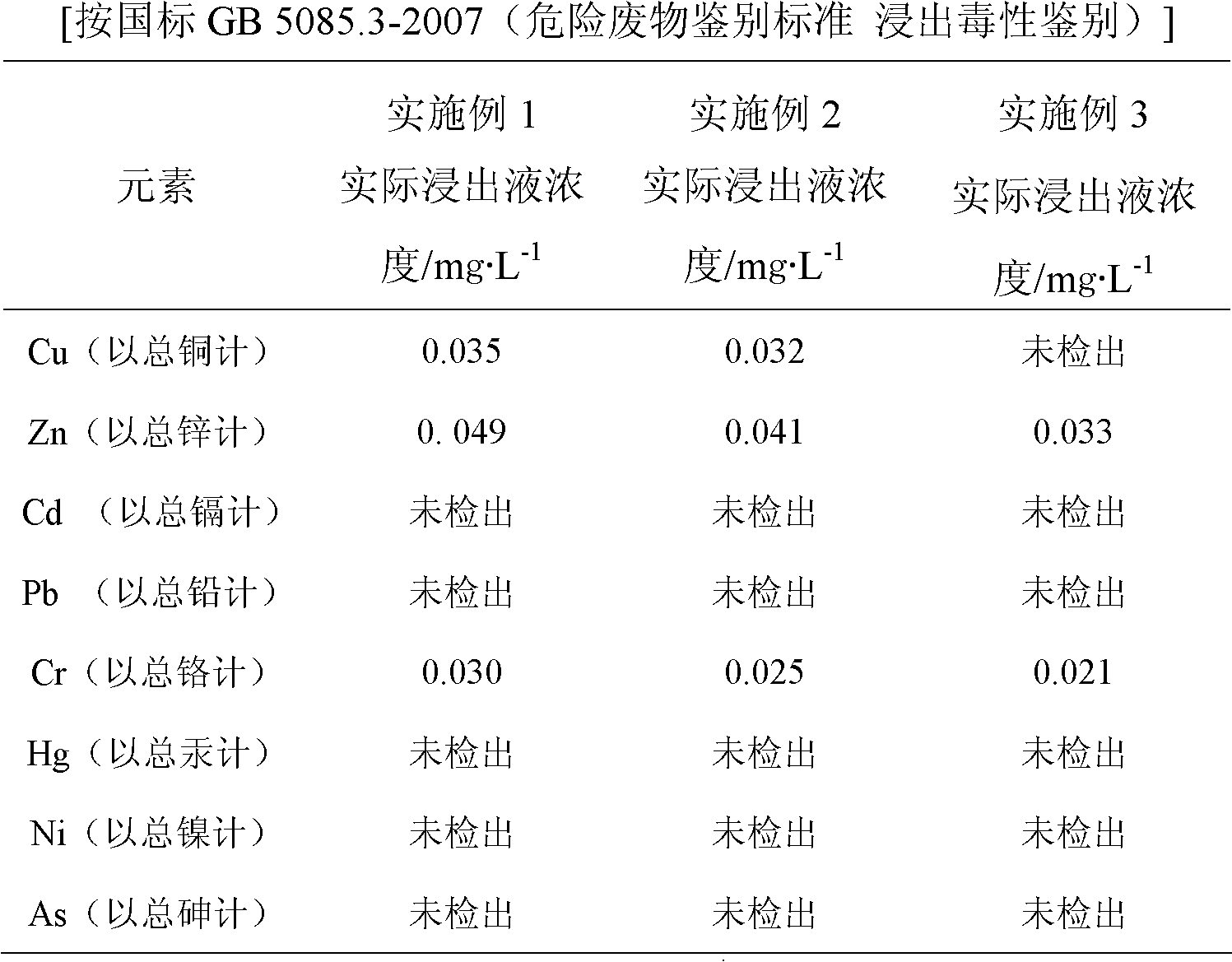

[0030] Table 1 Analysis of heavy metal content in leaching solution in activated carbon leaching toxicity identification test

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com