Method for blasting seepage enhancement for low infiltration sandrock -type uranium deposit

A sandstone-type, low-permeability technology is applied in the field of improving the permeability of low-permeability ore-bearing rock formations, and in the field of low-permeability ore deposits improving the permeability of their ore-bearing rock formations, which can solve problems that are not conducive to the full reaction of leachate and uranium minerals, and that the ore layer is unfavorable to the ground. It solves the problems of leaching and mining, unfavorable solution migration, etc., to achieve the effect of reasonable energy utilization of explosives, uniform infiltration effect, and improved energy utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

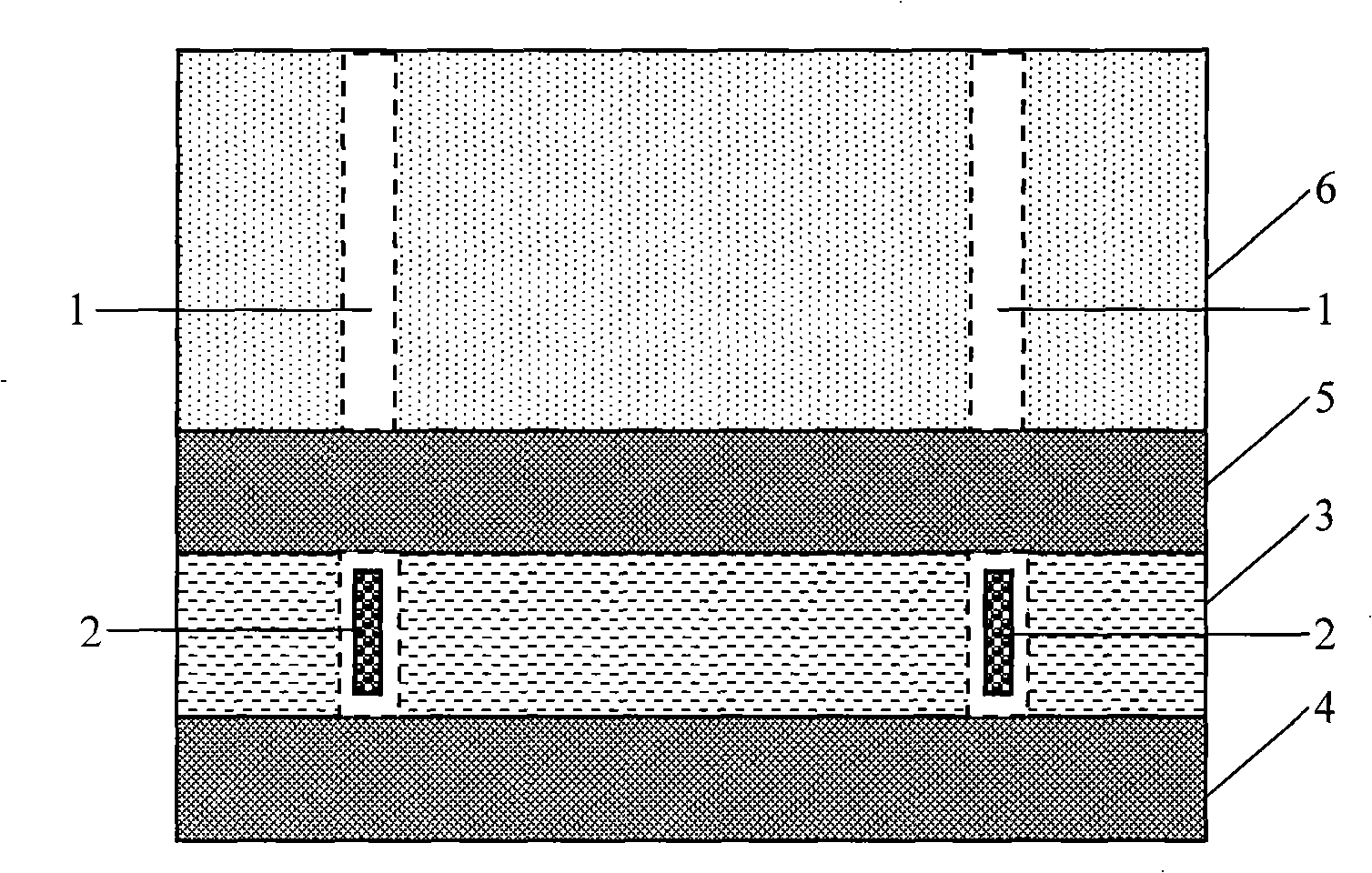

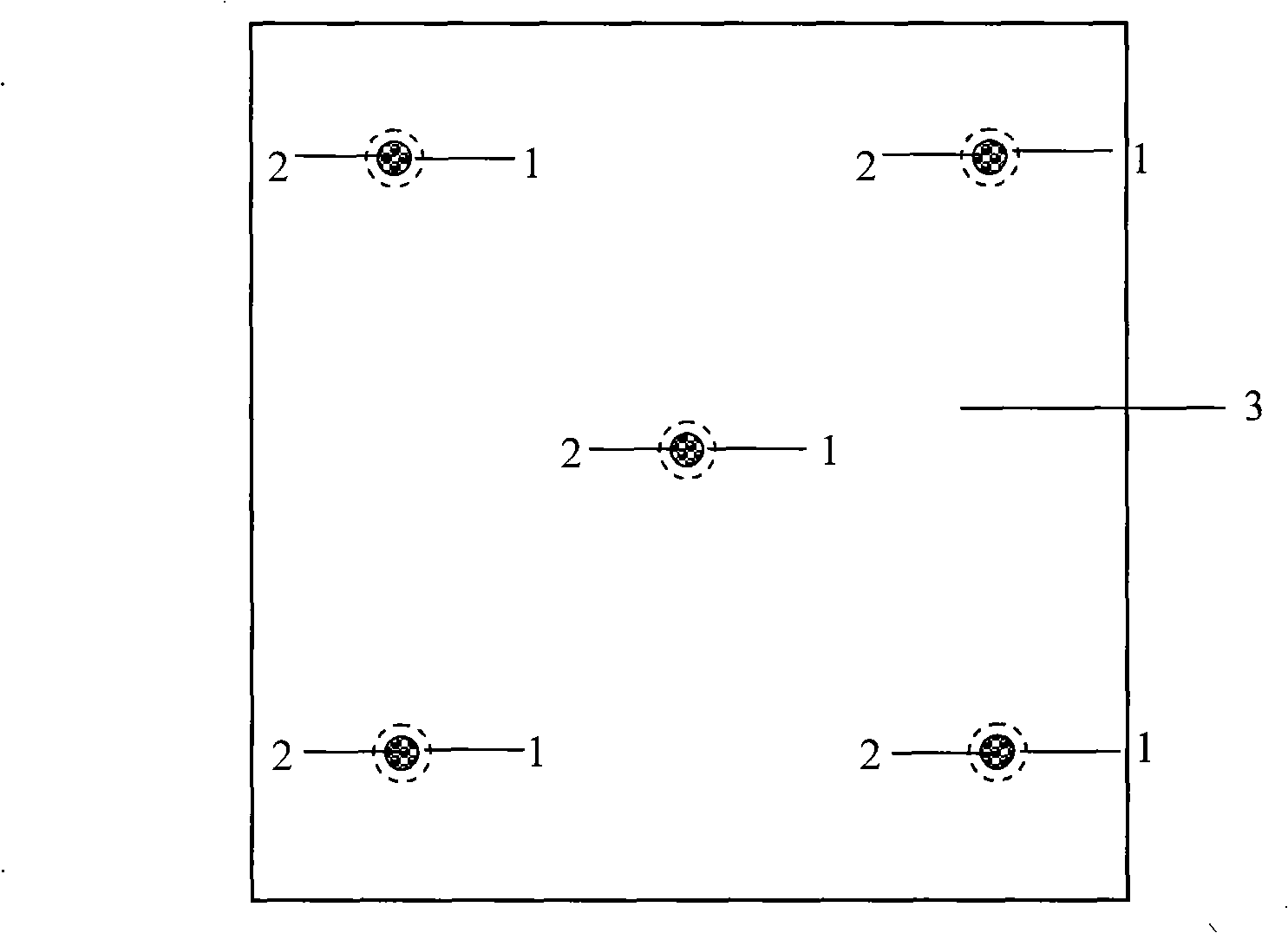

[0023] according to figure 1 , figure 2 It can be seen that a method for blasting and increasing permeability of a low-permeability sandstone type uranium deposit has the following steps:

[0024] A. Drill the blast hole 1 from the surface to the appropriate position of the ore-bearing rock layer 3 through the covering rock layer 6 and the upper roof rock layer 5 of the ore-bearing rock layer to avoid disturbing the bottom plate rock layer 4 of the ore-bearing rock layer. The position of the blast hole is determined according to the position of the injection hole in the in-situ leaching mining process, such as figure 2 Five-point wells are used to arrange the blastholes, the distance between the four-corner blastholes is 20 meters, the distance between the middle blasthole and the four-corner blastholes is 14 meters, or the distance between the four-corner blastholes is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com