Machinable brass alloy and preparation method thereof

A brass alloy, cutting processing technology, applied in the field of alloys, can solve the problems of low strength, hardness, creep resistance and fatigue strength of zinc and aluminum alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 15

[0067] The formula of embodiment 1 to embodiment 15 is as shown in table 1.

[0068] Among them, Example 1 and Example 2 are HPb59-1 and C36000 lead brass alloys, which are produced according to the conventional process steps of casting, extrusion, drawing, straightening, and annealing.

Embodiment 3 to Embodiment 15

[0069] The preparation method of embodiment 3 to embodiment 15 is as follows:

[0070] The ingredients of each component are smelted in a low-frequency melting furnace, and the ingot is cast vertically and semi-continuously. The casting temperature is 990°C-1030°C, and it is heated and extruded into a Φ20mm billet. The extrusion temperature is 630°C-670°C , drawn into a Φ19mm billet, and then stress-relieved annealed at 250°C-280°C, the heating rate of stress-relieved annealing is 40-45°C / min when it is below 200°C, and 5-8°C / min when it is above 200°C. The stress relief annealing cooling rate is 5-7°C / min when the temperature is above 300°C, and 45-48°C / min when the temperature is below 300°C. Finally, straighten and measure the finished billet. The obtained billet was sampled, and the content of each element in each sample of Example 1 to Example 15 was tested according to GB / T5121-2008, and the results are shown in Table 1.

[0071] The obtained billet was sampled and pre...

Embodiment 4

[0083] The surface color of embodiment 4, embodiment 5, embodiment 7, embodiment 11, embodiment 12, embodiment 13 cutting force sample after turning is as follows Figure 5 shown. Depend on Figure 5 It can be seen that when the Mn content is below 6.0wt%, the surface of the machinable brass alloy is bright yellow, and when the Mn content is above 6wt%, the surface color of the machinable brass alloy is whitish, and the Mn content reaches 9.0wt%. , the surface color of the brass alloy is white.

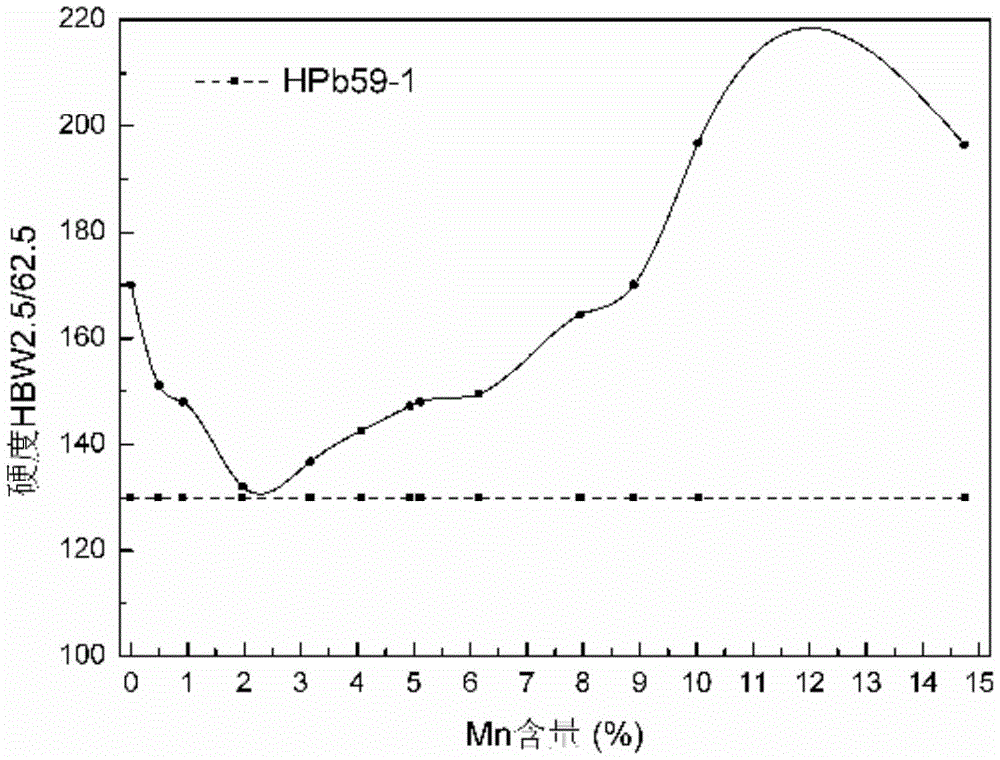

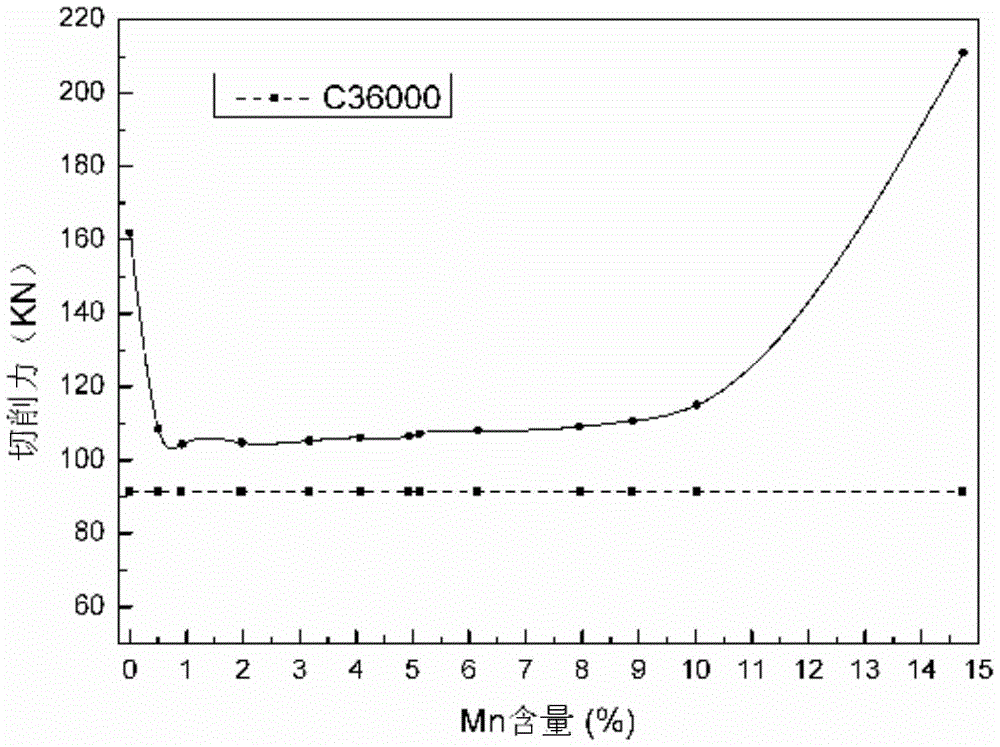

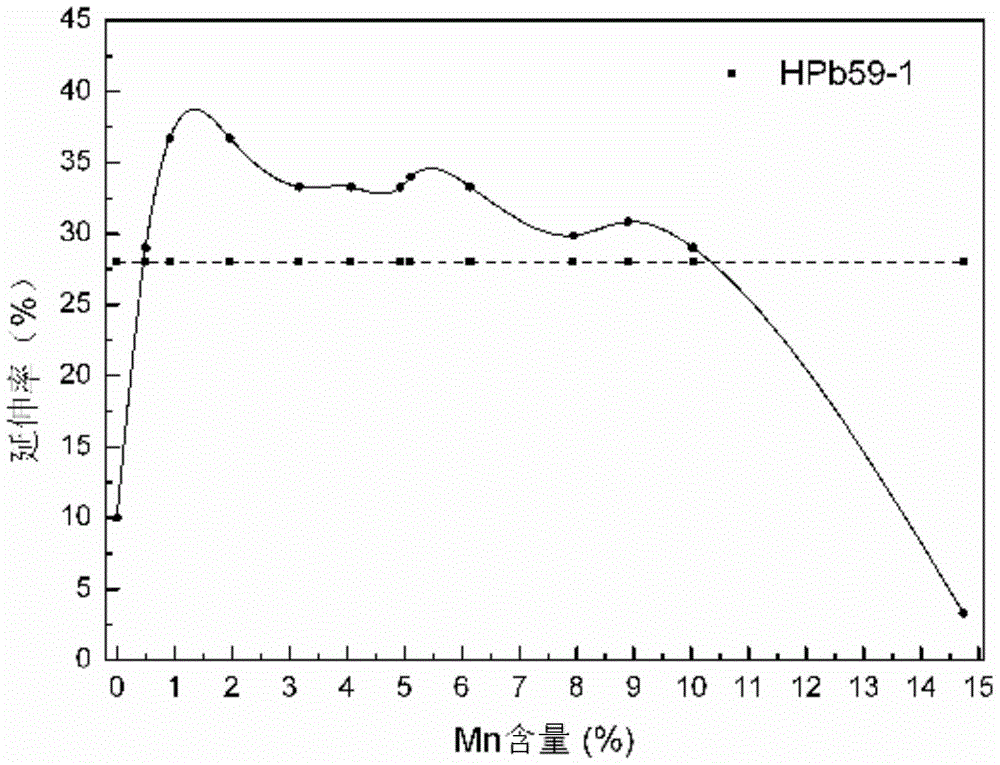

[0084] In summary, it can be seen that the content of Mn element is 0.5wt%-9.0wt%, the effect is better when the Mn content is 1.0wt%-6.0wt%, and the ideal Mn content is 1.3wt%-4.9wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com