Deep coal and coal bed gas combined mining method

A technology of combined mining and coalbed methane, which is applied in coal gasification, mining fluid, earth drilling and mining, etc., can solve problems such as inability to mine, no one to conduct research and development, and no similar technology for coalbed methane mining, so as to alleviate energy shortage, The effect of low cost and reduced investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

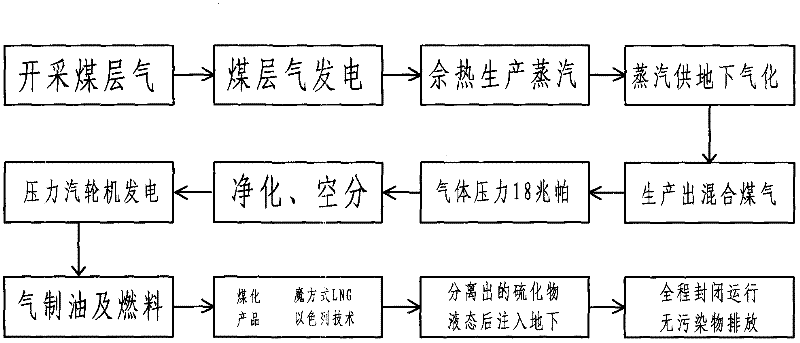

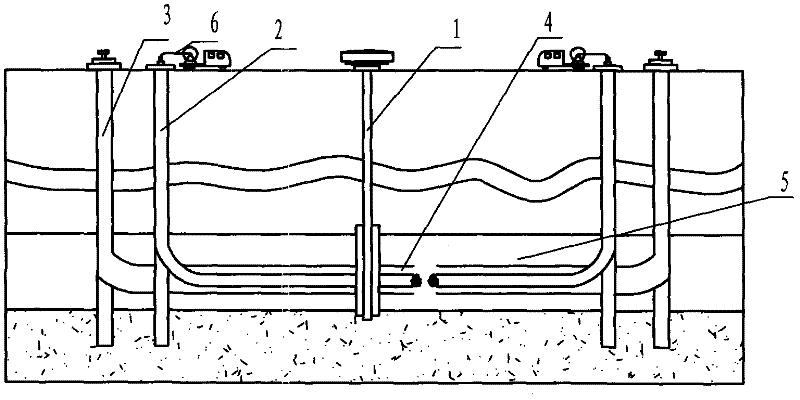

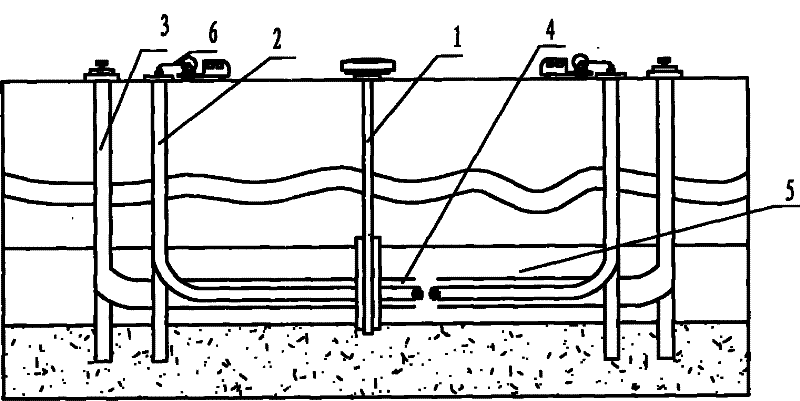

[0028] Example: see attached figure 1 , 2 , deep coal and coalbed methane joint mining technology is characterized in that it includes the following steps:

[0029] 1. The coal seam must be buried at a depth of 800 meters to 3000 meters, with a thickness of more than 3 meters, an inclination angle of less than 10°, and a pressure of more than 10 MPa. The most advanced drilling and cementing, high temperature resistance, and high pressure completion technologies in the petroleum industry must be adopted. Horizontal wells are combined with gas injection and gas production; three vertical wells are drilled first, with a well spacing of 500 meters; two wells are drilled to the side of the central well for more than 500 horizontal wells. Meter-long channel, dedicated gasification channel for gas production, observation, monitoring, etc., drill multiple super-long horizontal wells in the opposite direction according to the dip angle of the coal seam, 1000-1500 meters, and perform l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com