Method for regenerating APT (ammonium paratungstate) by use of APT waste low-grade tungsten slag

A technology of tungsten slag and concentration, which is applied in the field of recycling and reuse of tungsten resources, can solve the problems of high requirements for the impurity removal process, affecting the stability of process parameters, and relatively large process impact, so as to extend the service life, reduce emissions, and improve The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

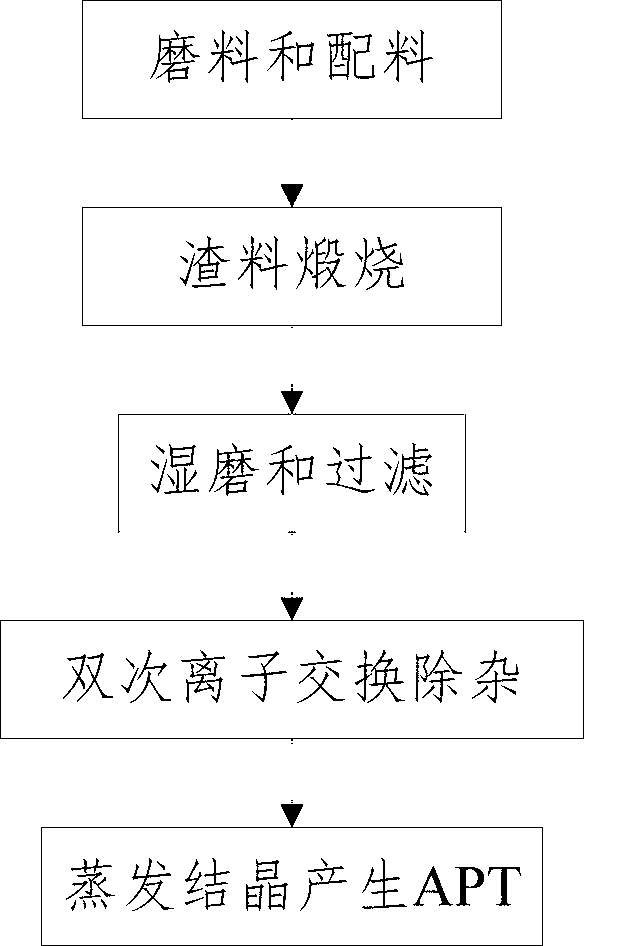

Image

Examples

Embodiment 1

[0022] a. Abrasives and ingredients: Grind APT waste low-grade tungsten slag to -125 mesh ≥ 90%, take WO 3 The grade is allocated to 100kg of 4% waste low-grade tungsten slag material, and then the batching is carried out. The addition of soda in the batching is 5.4kg, and the addition of saltpeter in the batching is 0.08kg;

[0023] b. Slag calcining: Calcining the slag prepared in step a in a rotary kiln, the temperature of the firing zone is 1000-1100°C, the rotating speed of the rotary kiln is 0.3r / min, and the temperature of the kiln tail smoke chamber is 800—850°C, pressure -110——150Pa; outlet temperature of preheater is 230—245°C, inlet pressure is -120——160Pa, outlet pressure is -7000——7100Pa; kiln head cover temperature is 700 -750°C; the calcination time is 1.6h, and the sintered material is generated after the calcination is completed;

[0024] c. Wet grinding and filtering: Add demineralized water to the sintered material for wet grinding, the liquid-solid ratio i...

Embodiment 2

[0029] a. Abrasives and ingredients: Grind APT waste low-grade tungsten slag to -125 mesh ≥ 90%, take WO 3 The grade is allocated to 100kg of waste low-grade tungsten slag material of 8%, and then the batching is carried out. The addition of soda in the batching is 11.6kg, and the addition of saltpeter in the batching is 0.224kg;

[0030] b. Slag calcining: Calcining the slag prepared in step a in a rotary kiln, the temperature of the firing zone is 1250-1350°C, the rotating speed of the rotary kiln is 1.3r / min, and the temperature of the kiln tail smoke chamber is 900—950°C, pressure -180——190Pa; outlet temperature of preheater: 270—280°C, inlet pressure: -190——200Pa, outlet pressure: -7300——7500Pa; kiln hood temperature: 780 —800°C; the calcination time is 2.5h, and the sintered material is generated after the calcination is completed;

[0031] c. Wet grinding and filtering: Add demineralized water to the sintered material for wet grinding, the liquid-solid ratio is 1.85:1,...

Embodiment 3

[0036] a. Abrasives and ingredients: Grind APT waste low-grade tungsten slag to -125 mesh ≥ 90%, take WO 3 100kg of waste low-grade tungsten slag material with a grade of 6% is blended, and then the batching is carried out. The addition of soda in the batching is 8.4kg, and the addition of saltpeter in the batching is 0.126kg;

[0037] b. Calcining of slag: Calcining the slag prepared in step a in a rotary kiln, the temperature of the firing zone is 1100-1250°C, the rotating speed of the rotary kiln is 0.9r / min, and the temperature of the kiln tail smoke chamber is 850—900°C, pressure -150——180Pa; outlet temperature of preheater is 245—270°C, inlet pressure is -140——190Pa, outlet pressure is -7100——7300Pa; kiln head cover temperature is 750 —780°C; the calcination time is 1.8h, and the sintered material is formed after the calcination is completed;

[0038] c. Wet grinding and filtering: Add demineralized water to the sintered material for wet grinding, the liquid-solid ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com