Preparation method for papermaking argillaceous activated carbon adsorption material

A technology of activated carbon adsorption and mud, which is applied in chemical instruments and methods, adsorption water/sewage treatment, sludge treatment, etc., to achieve the effects of low treatment temperature, low raw material cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

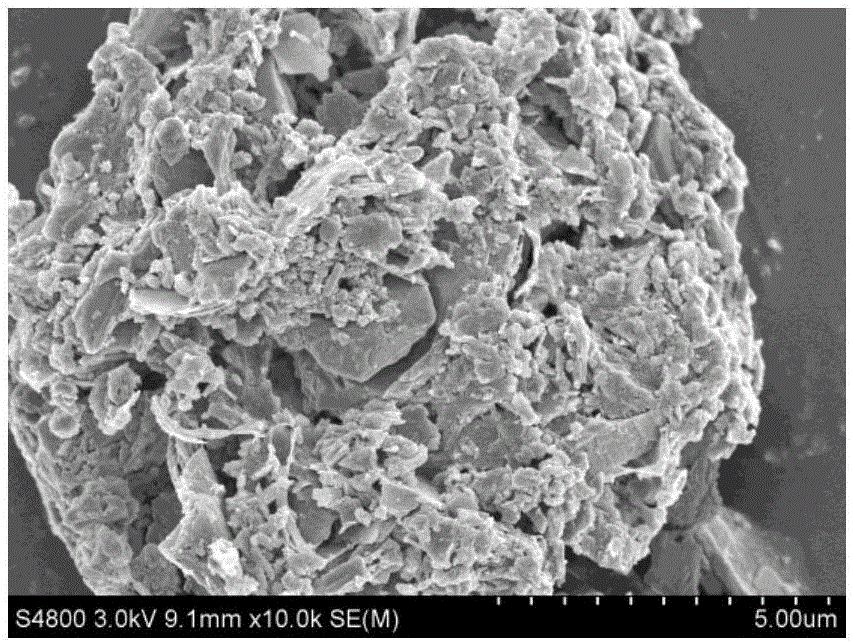

Image

Examples

Embodiment 1

[0027] Step 1. The biochemical sludge (primary, secondary and tertiary mixed sludge of the paper mill) is concentrated, squeezed and dried to a moisture content below 10%, ground and sieved to retain the average particle size 200 mesh sludge particles;

[0028] Step 2. Add the sludge particles obtained in Step 1 to a zinc chloride activator with a concentration of 3mol / L for activation treatment for 24 hours, with a stirring rate of 90r / min, and a weight ratio of sludge particles to zinc chloride solution of 1:3. Then dehydrated and dried;

[0029] Step 3. Put the sludge particles treated in step 2 into the pyrolysis furnace. Before carbonization, nitrogen is introduced to drive off the air in the pyrolysis furnace to prevent the sludge from being oxidized. The purge rate is 200mL / min, and then Use nitrogen as the protective gas, heat up to 500°C at a rate of 30°C / min, and hold for 30 minutes;

[0030] Step 4. The carbonized product is immersed in a hydrochloric acid solution with ...

Embodiment 2

[0033] Step 1: Concentrate, squeeze, and dry the biochemical sludge from the pulp and paper wastewater treatment plant to a moisture content of less than 10%, grind and sieving, and retain sludge particles with an average particle size of 200 mesh;

[0034] Step 2. Add the sludge particles obtained in step 1 to a zinc chloride activator with a concentration of 1mol / L for activation treatment for 48 hours, with a stirring rate of 60r / min, and a weight ratio of sludge particles to zinc chloride solution of 1:1. Then dehydrated and dried;

[0035] Step 3. Put the sludge particles treated in step 2 into the pyrolysis furnace. Before carbonization, nitrogen is introduced to drive off the air in the pyrolysis furnace to avoid oxidation of the sludge. The purge rate is 100mL / min. Use nitrogen as the protective gas, heat up to 700°C at a rate of 40°C / min and then keep it for 10 minutes;

[0036] Step 4, the carbonized product is immersed in a hydrochloric acid solution with a concentration ...

Embodiment 3

[0038] Step 1: Concentrate, squeeze, and dry the biochemical sludge from the pulp and paper wastewater treatment plant to a moisture content of less than 10%, grind and sieving, and retain sludge particles with an average particle size of 200 mesh;

[0039] Step 2. Add the sludge particles obtained in step 1 to a zinc chloride activator with a concentration of 5mol / L for activation treatment for 12 hours, with a stirring rate of 120r / min, and a weight ratio of sludge particles to zinc chloride solution of 1:4. Then dehydrated and dried;

[0040] Step 3. Put the sludge particles treated in step 2 into the pyrolysis furnace. Before carbonization, nitrogen is introduced to drive off the air in the pyrolysis furnace to avoid oxidation of the sludge. The purge rate is 150mL / min. Use nitrogen as the protective gas, heat up to 400°C at a rate of 10°C / min and keep it for 90 minutes;

[0041] Step 4: The carbonized product is immersed in a hydrochloric acid solution with a concentration of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com