Automatic batching method and automatic batching system for asphalt mixing station and asphalt mixing station

An asphalt mixing plant and automatic batching technology, applied in the field of asphalt mixing plants, can solve the problems of high skill level requirements for operators, affecting equipment production capacity, mismatching aggregate particles, etc., to ensure equipment production capacity and avoid hot silos Effects of short and flash problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

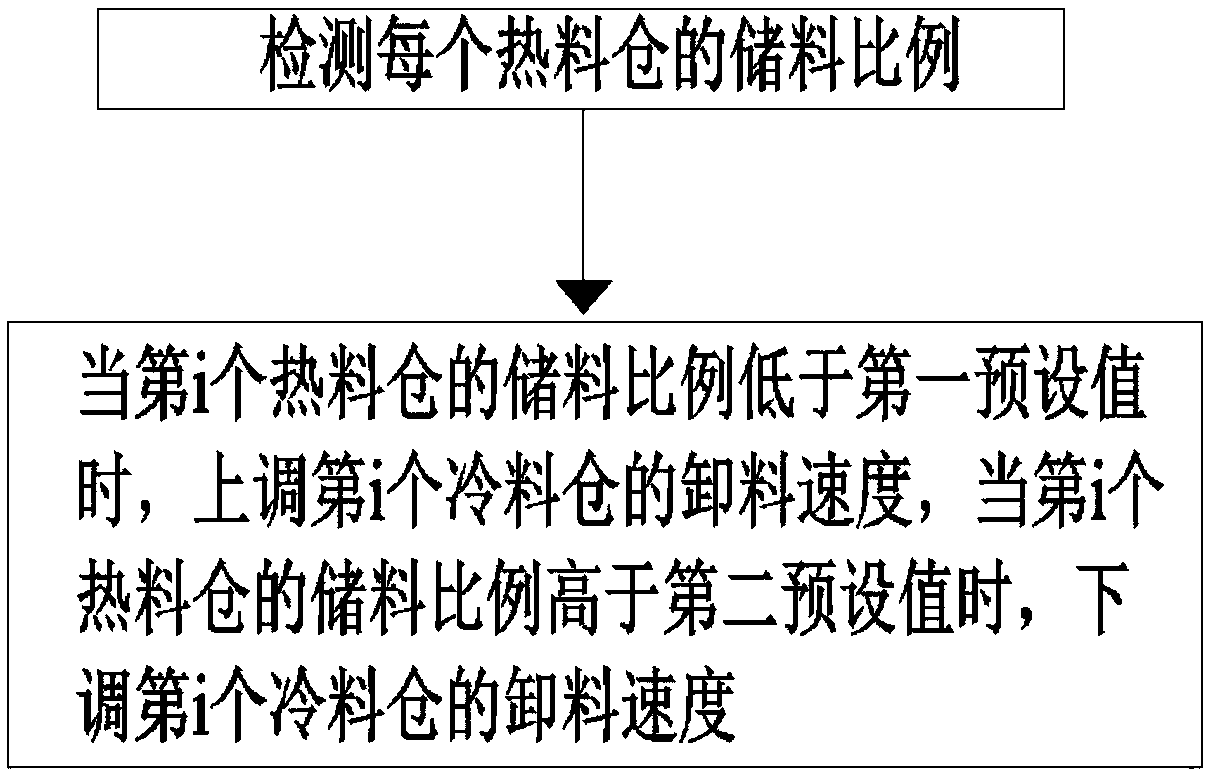

[0047] Such as figure 1 As shown, the present invention provides an automatic batching method for an asphalt mixing plant. The asphalt mixing plant includes 4 cold silos 1 and 4 hot silos 6 for storing aggregates with different particle sizes and specifications. The first cold silo The average particle size of the aggregates stored in the silo 1, the second cold silo 1...the fourth cold silo 1 increases sequentially, the first hot silo 6, the second hot silo 6... The average particle size of aggregates stored in the fourth hot silo 6 increases sequentially, the first cold silo 1 corresponds to the first hot silo 6, and the second cold silo 1 corresponds to the second hot silo 6... The fourth cold feed bin 1 corresponds to the fourth hot feed bin 6, and the automatic batching method includes the following steps:

[0048] Step 102: Obtain the material storage ratio of each hot material bin 6;

[0049] Step 104: When the storage ratio of the i-th hot hopper 6 is lower than 30%,...

Embodiment 2

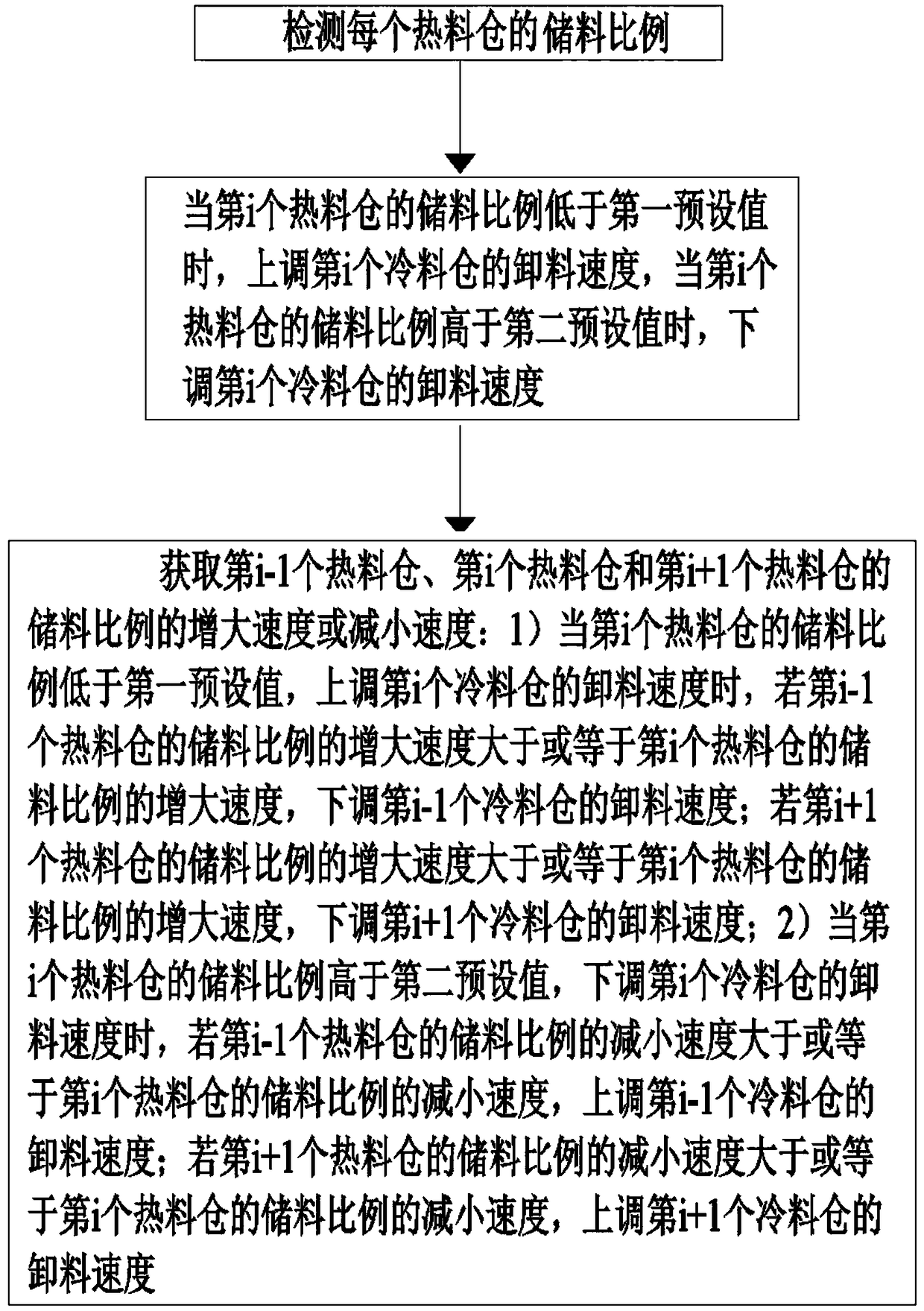

[0053] Such as figure 2 As shown, the present invention provides an automatic batching method for an asphalt mixing plant. The asphalt mixing plant includes 5 cold silos 1 and 5 hot silos 6 for storing aggregates with different particle sizes and specifications. The first cold silo Silo 1, the second cold silo 1...the average particle size of the aggregates stored in the fifth cold silo 1 increases sequentially, the first hot silo 6, the second hot silo 6... The average particle size of the aggregate stored in the fifth hot silo 6 increases sequentially, the first cold silo 1 corresponds to the first hot silo 6, and the second cold silo 1 corresponds to the second hot silo 6...the fifth cold feed bin 1 corresponds to the fifth hot feed bin 6, and the automatic batching method includes the following steps:

[0054] Step 102: Obtain the material storage ratio of each hot material bin 6;

[0055] Step 104: When the storage ratio of the i-th hot hopper 6 is lower than 20%, incr...

Embodiment 3

[0059] Such as figure 2 As shown, the present invention provides an automatic batching method for an asphalt mixing plant. The asphalt mixing plant includes 5 cold silos 1 and 5 hot silos 6 for storing aggregates with different particle sizes and specifications. The first cold silo Silo 1, the second cold silo 1...the average particle size of the aggregates stored in the fifth cold silo 1 increases sequentially, the first hot silo 6, the second hot silo 6... The average particle size of the aggregate stored in the fifth hot silo 6 increases sequentially, the first cold silo 1 corresponds to the first hot silo 6, and the second cold silo 1 corresponds to the second hot silo 6...the fifth cold feed bin 1 corresponds to the fifth hot feed bin 6, and the automatic batching method includes the following steps:

[0060] Step 102: Obtain the material storage ratio of each hot material bin 6;

[0061] Step 104: When the storage ratio of the i-th hot hopper 6 is lower than 55%, incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com