Lifting vertical vortex pipeline pump

A pipeline pump and eddy current technology, applied in non-variable volume pumps, pumps, components of pumping devices for elastic fluids, etc., can solve the problems of reducing construction efficiency, unfavorable transportation, pipeline pump overflow, etc. Connection accuracy and connection strength, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

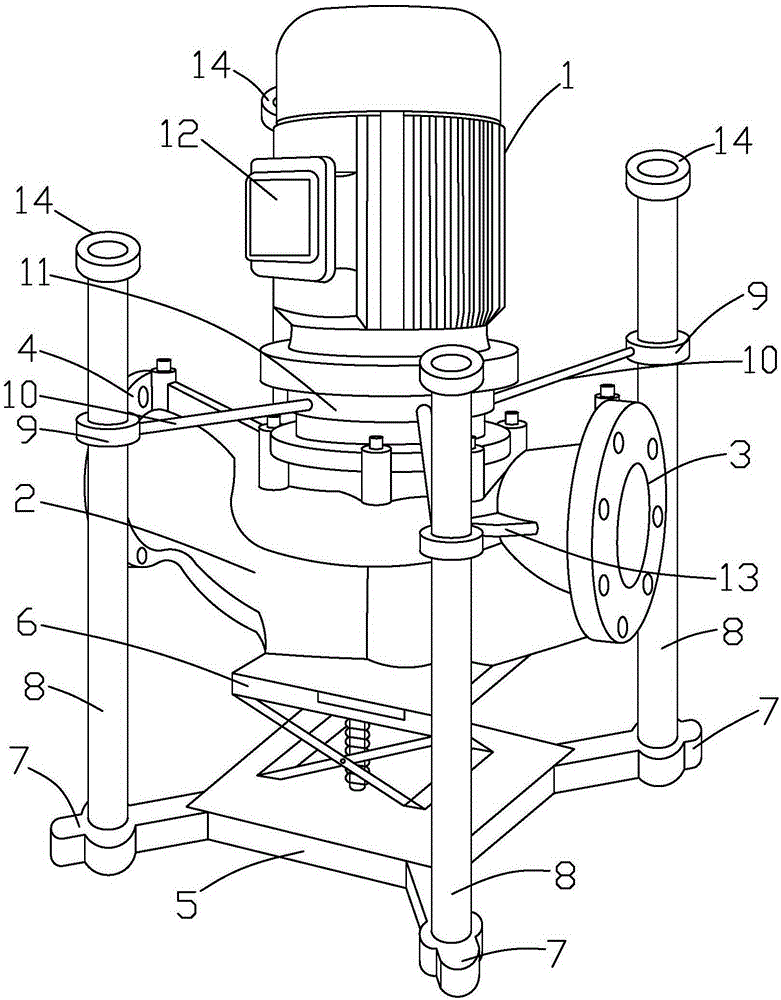

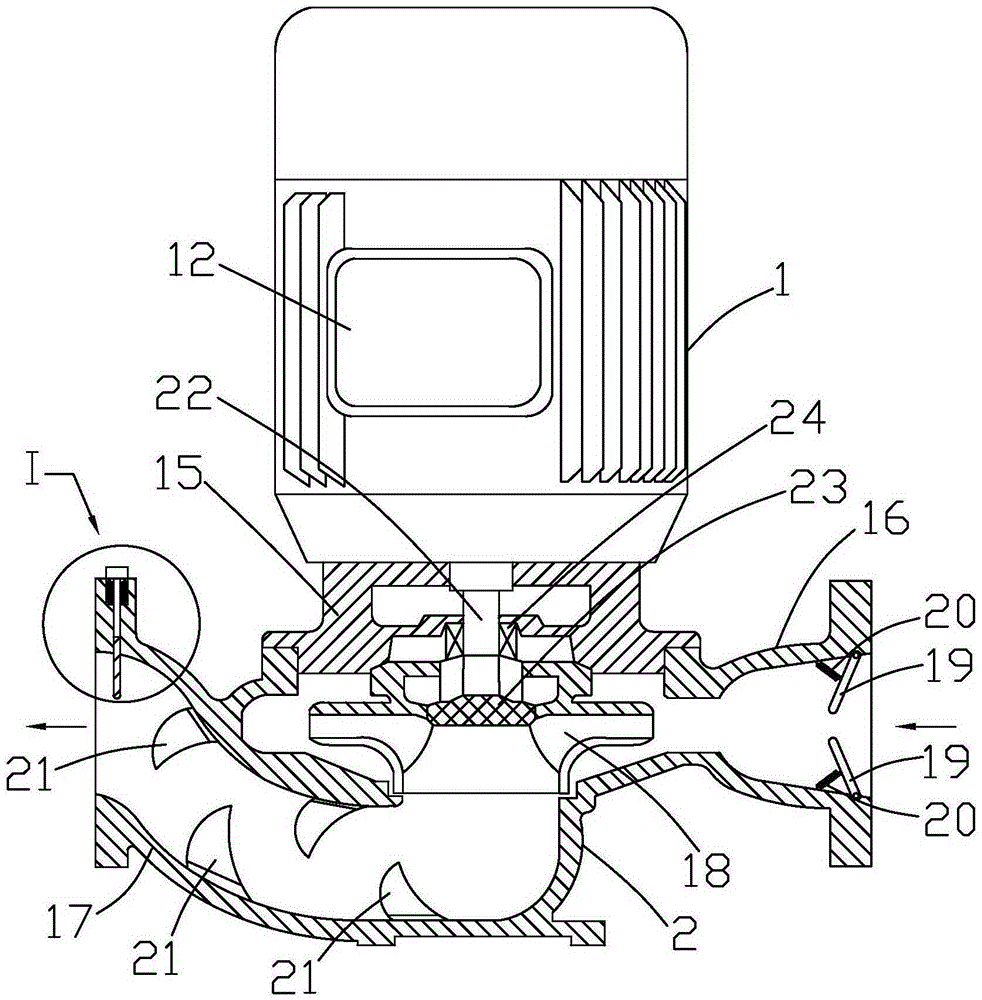

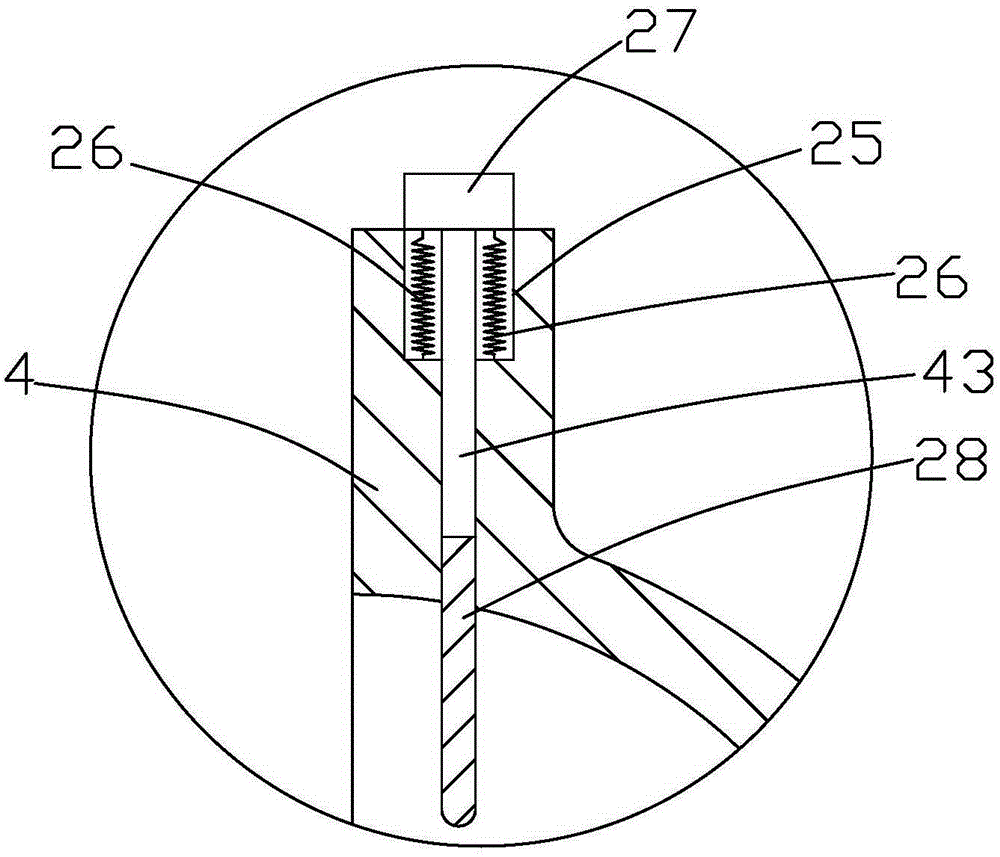

[0028] Such as Figure 1 to Figure 5As shown, it is a lifting vertical vortex pipeline pump according to the present invention, which includes a first motor 1 and a pump body 2, a power cord box 12 is arranged on the first motor 1, and a middle bearing is passed between the first motor 1 and the pump body 2. The seat 15 is fixedly connected, and the left and right sides of the pump body 2 are respectively provided with a liquid outlet pipe 17 and a liquid inlet pipe 16. The liquid inlet pipe 16 and the liquid outlet pipe 17 are all fixedly connected to the pump body 2 through the reinforcing rib 13, and the reinforcing rib 13 can effectively Improve the connection strength between the liquid inlet pipe 16, the liquid outlet pipe 17 and the pump body 2 to prolong the service life of the pipeline pump. The ends of the liquid outlet pipe 17 and the liquid inlet pipe 16 are respectively provided with a liquid outlet flange 4 and a The liquid inlet flange 3 and the liquid outlet fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com