Movable type hydraulic pumping station

A hydraulic pump station, mobile technology, applied in the direction of fluid pressure actuation device, accumulator device, etc., can solve the problems of mobile hydraulic pump station, such as dirt, malfunction, labor and time, etc., to achieve structural Compact, guaranteed clean and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

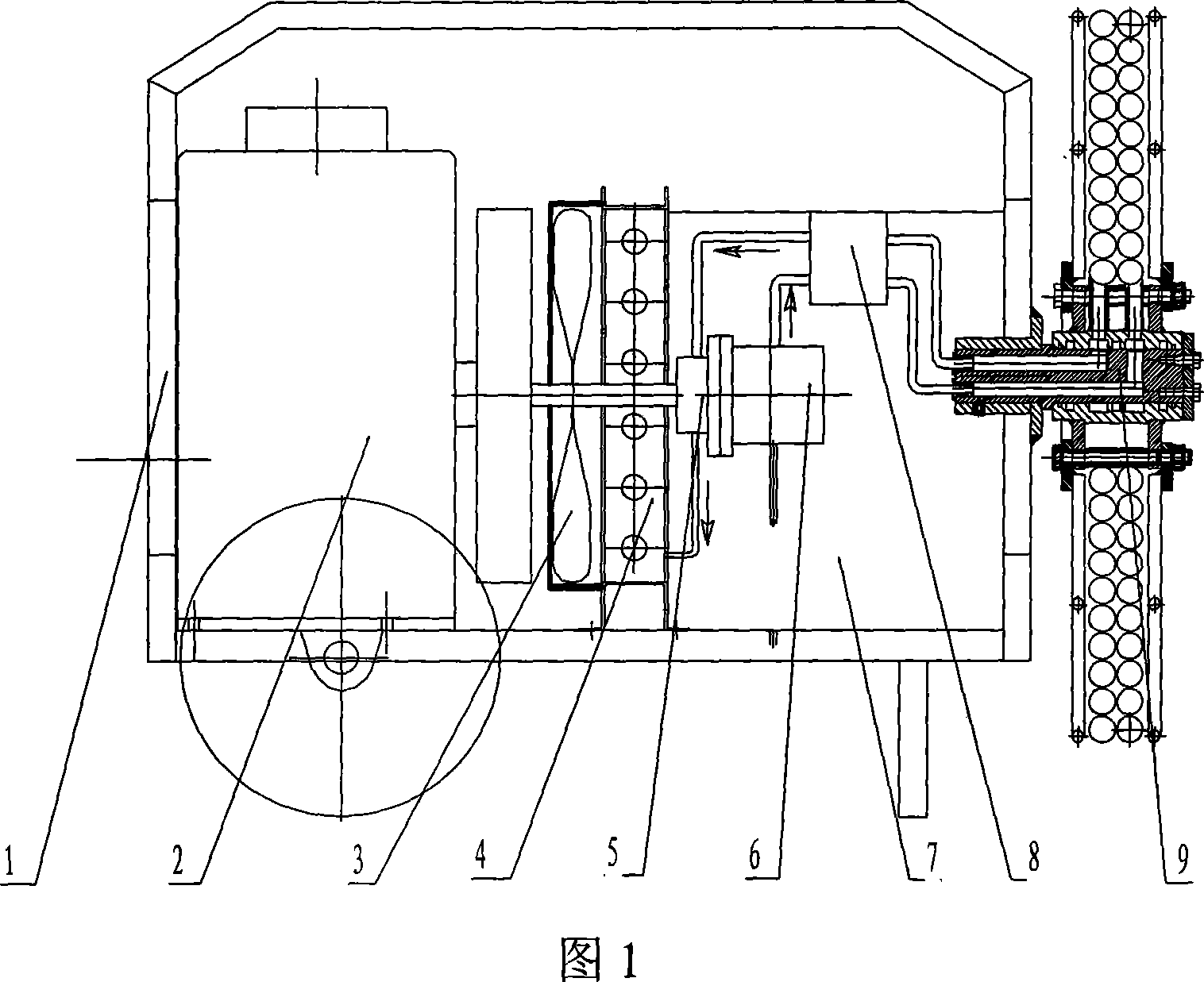

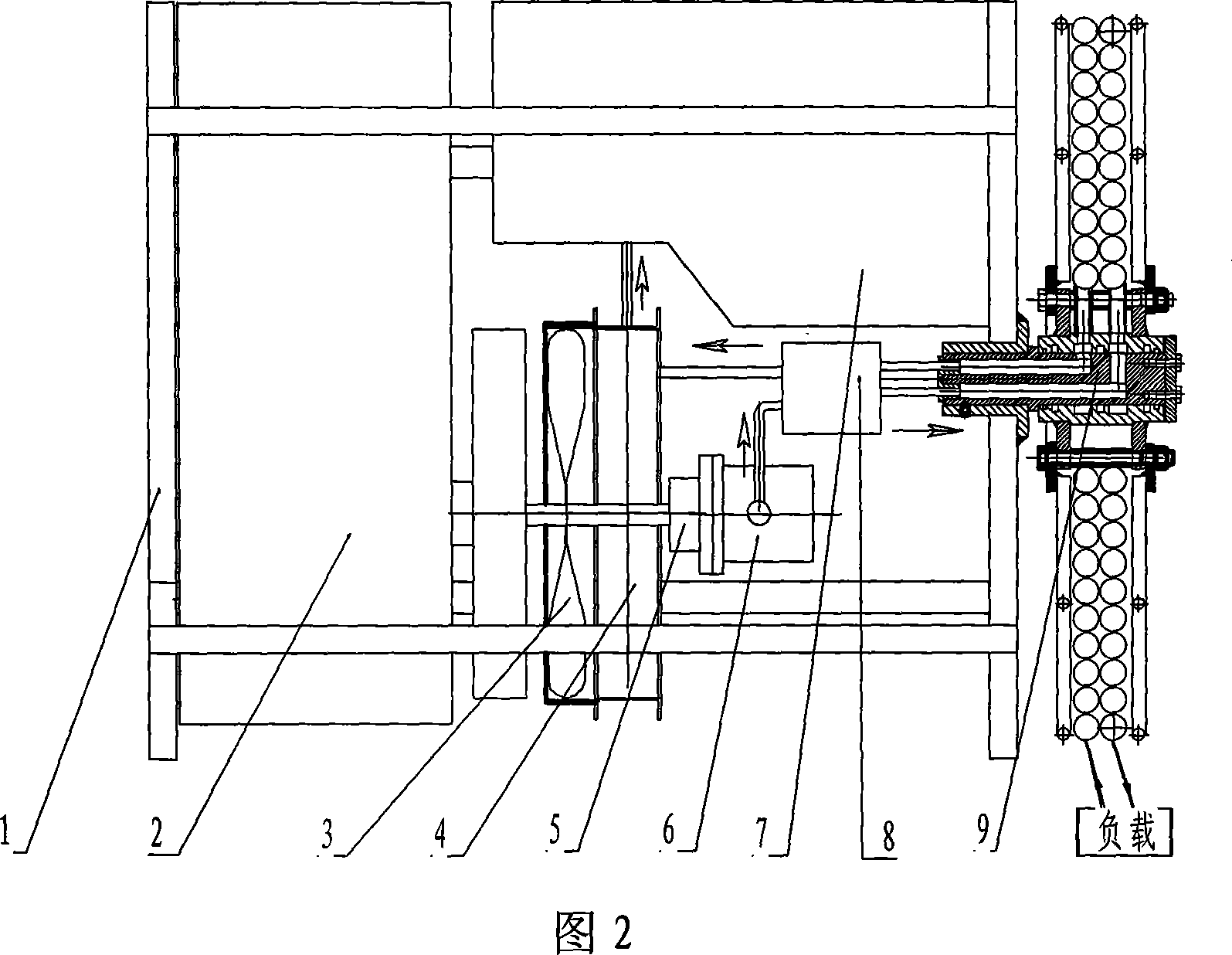

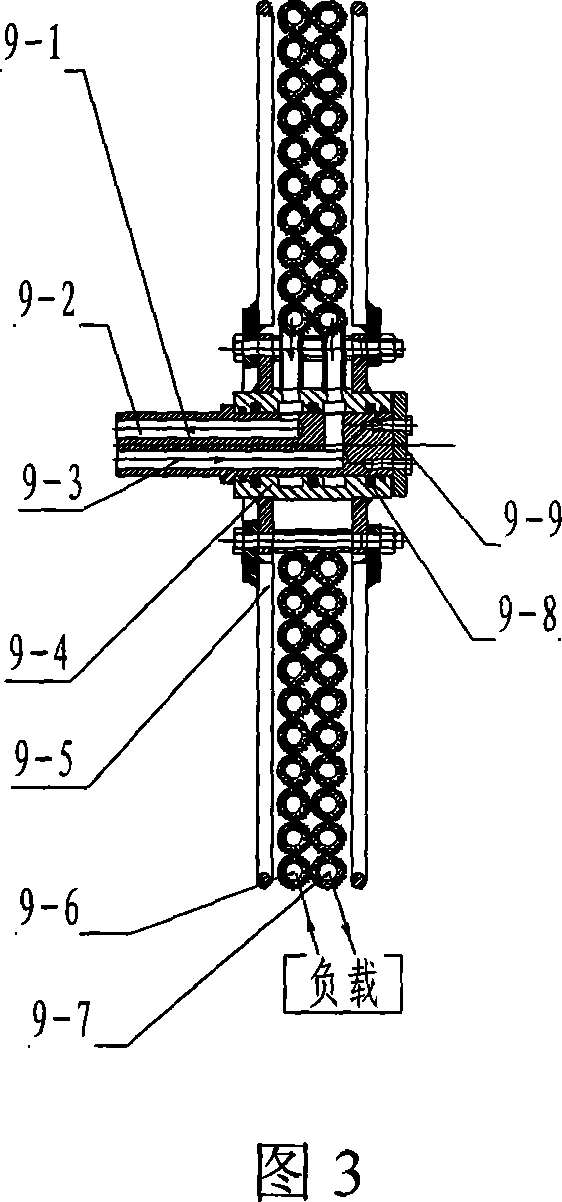

[0018] Embodiment 1: In the figure, 1. vehicle frame; 2. power machine; 3. fan; 4. radiator; 5. coupling; 6. oil pump; 7. fuel tank; 8. hydraulic control valve; 9. pipe winder; 9-1, mandrel; 9-2, oil outlet hole; 9-3, oil inlet hole; 9-4 mandrel jacket; 9-5, coiling frame; 9-6, oil return pipe; 9-7, inlet Oil pipe; 9-8, sealing ring; 9-9, jacket baffle; 9-10, elastic circlip.

[0019] In Fig. 1, Fig. 2 and Fig. 3, the hydraulic pump station has vehicle frame 1, power machine 2, oil tank 7, fan 3, radiator 4, coupling 5, oil pump 6, hydraulic control valve 8, load and A pipe winder 9, a power machine 2, an oil tank 7, a fan 3, a radiator 4, a coupling 5, an oil pump 6, are installed in the vehicle frame 1, load And hydraulic control valve 8, described power machine is a diesel engine, fuel tank, oil pump, hydraulic control valve, pipe winder, load The radiator is connected sequentially through pipelines; the shaft at one end of the coupling is connected to the diesel engine...

Embodiment 2

[0023] Embodiment 2: In Fig. 4, there are independent oil inlet holes and oil outlet holes on the mandrel, the oil inlet holes and the oil outlet holes have axial holes and radial holes, and the axial holes communicate with the radial holes, There is an oil groove and a sealing ring groove on the mandrel, the position of the radial hole corresponds to the oil groove on the mandrel, and an axial limiter is connected to the mandrel, and the axial limiter is a circlip 9-10; The position of the overcoat radial hole on the mandrel overcoat corresponds to the oil groove on the mandrel.

[0024] Others are the same as in Embodiment 1, omitted.

Embodiment 3

[0025] Embodiment 3: In Figure 5, the pipe winder is connected with a pipe winding frame on the outside of the mandrel, and there are independent oil inlet holes and oil outlet holes on the mandrel, and the oil inlet holes and oil outlet holes have axial holes And the radial hole, the axial hole is connected with the radial hole, and the position of the radial hole corresponds to the oil groove inside the mandrel jacket; there are oil grooves and sealing ring grooves on the inner wall of the mandrel jacket, and there are Outer jacket radial hole, the outer jacket radial hole is an oil inlet hole and an oil outlet hole, the position of the outer jacket radial hole is corresponding to the oil groove on the mandrel jacket, and the mandrel jacket is a fixed body.

[0026] Others are the same as in Embodiment 1, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com