Can conveying device

A technology of can feeding and conveying chain, applied in the field of can filling and capping production line, can solve the problems of severe material spillage, track wear, and large friction between the material tank and the guide rail of the conveying tank, and achieves wide applicability, small contact surface, Reduce the effect of material spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

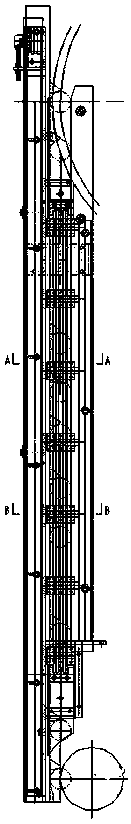

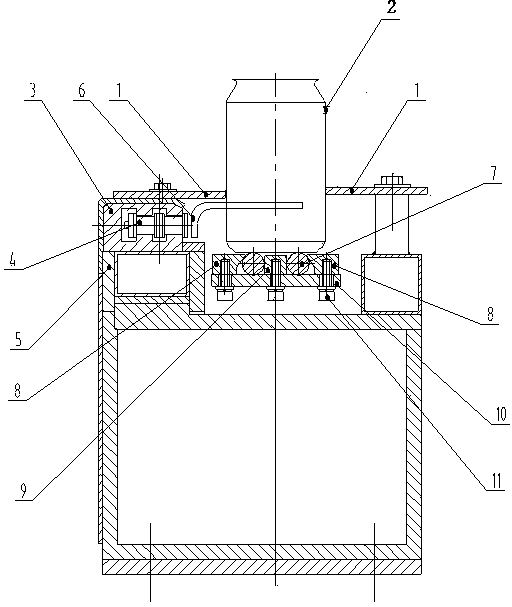

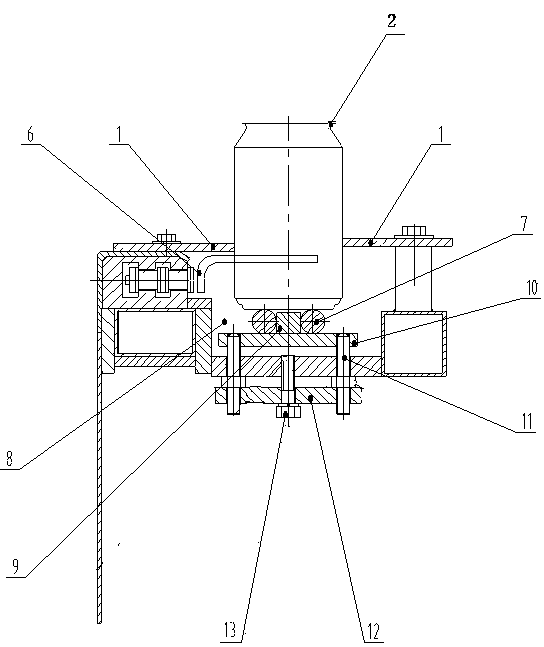

[0016] The top view when the present invention is applied to the can filling and capping production line is as follows figure 1 As shown, the device is installed between the filling machine and the capping machine, and includes the can conveying platform support 5 and the can conveying guide rail, the conveying chain guide rail 3 is arranged inside the can conveying platform support 5, and the conveying chain 4 is inside the conveying chain guide rail 3 The movement of the conveying chain 4 is connected with a claw 6, and the material tank 2 is driven by the claw 6 to move along the upper surface of the tank transport rail. The two sides of the material tank 2 are provided with a tank guard plate 1, which is characterized in that: the tank transport The guide rail includes a support plate 10 and several round steel guide rails 7 fixed on the support plate.

[0017] The rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com