Power station boiler membrane panel welding joint blind area X ray detection method

A technology of membrane wall tubes and power plant boilers, which is applied in the use of radiation for material analysis, etc., can solve problems such as missed detection of defects, hidden dangers of unit safe operation, etc., and achieve the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

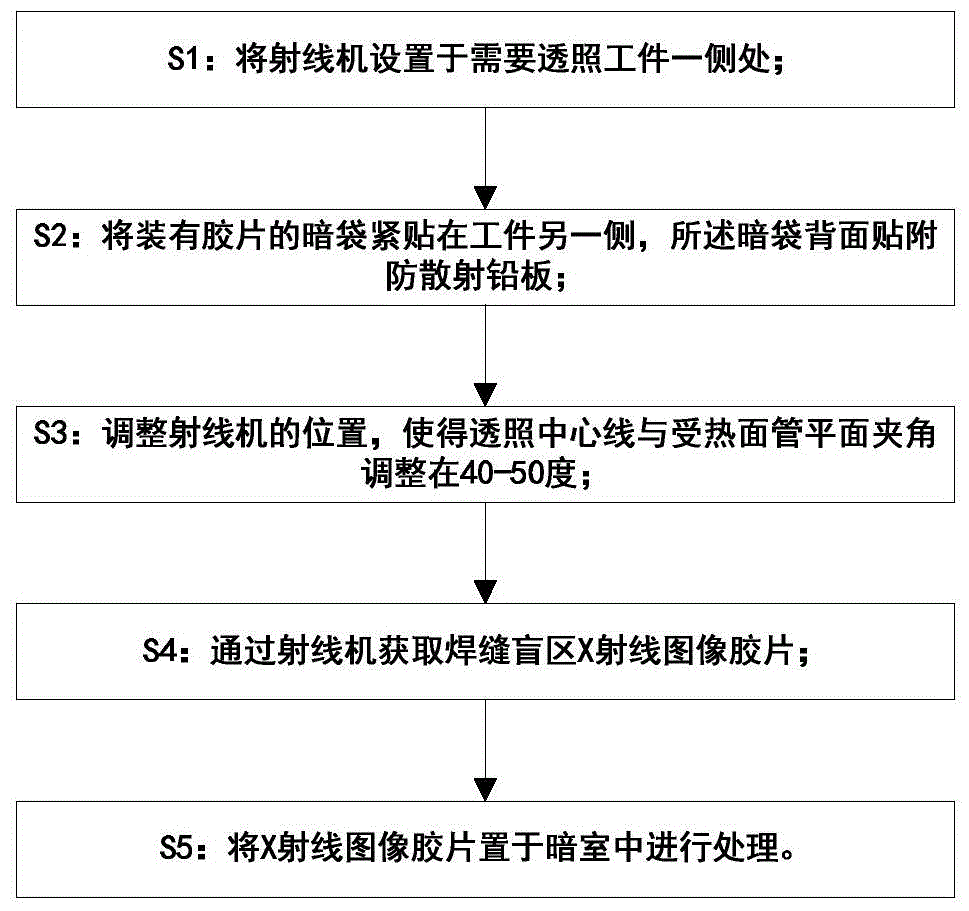

[0035] figure 1 The flow chart of the X-ray detection method for the blind area of the welded seam of the membrane wall tube of the power plant boiler provided by the embodiment of the present invention is shown in the figure: the X-ray detection method of the blind area of the welded seam of the membrane type wall tube of the power plant boiler provided by the present invention includes the following steps:

[0036] S1: Set the X-ray machine at the side where the workpiece needs to be transilluminated;

[0037] S2: stick the dark bag containing the film on the other side of the workpiece, and attach the anti-scatter lead plate to the back of the dark bag;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com