Material conveying device

A technology for conveying devices and materials, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., it can solve the problems that it is difficult to meet the requirements of material feeding, affect the efficiency of material processing, and the materials cannot be transported centrally, so as to improve the conveying efficiency, Ease of concentration and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

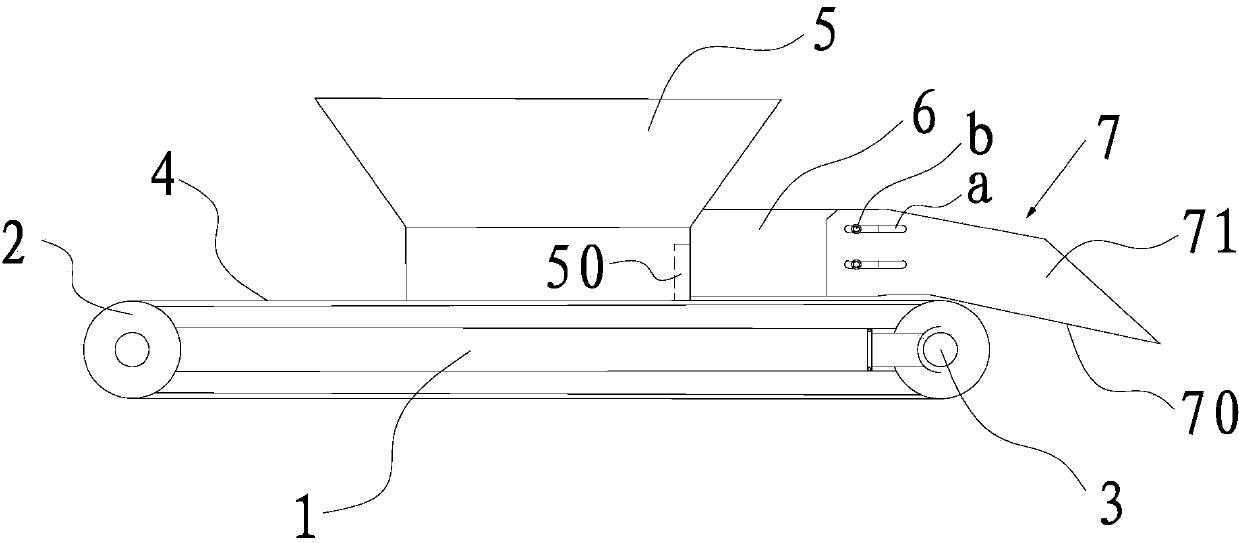

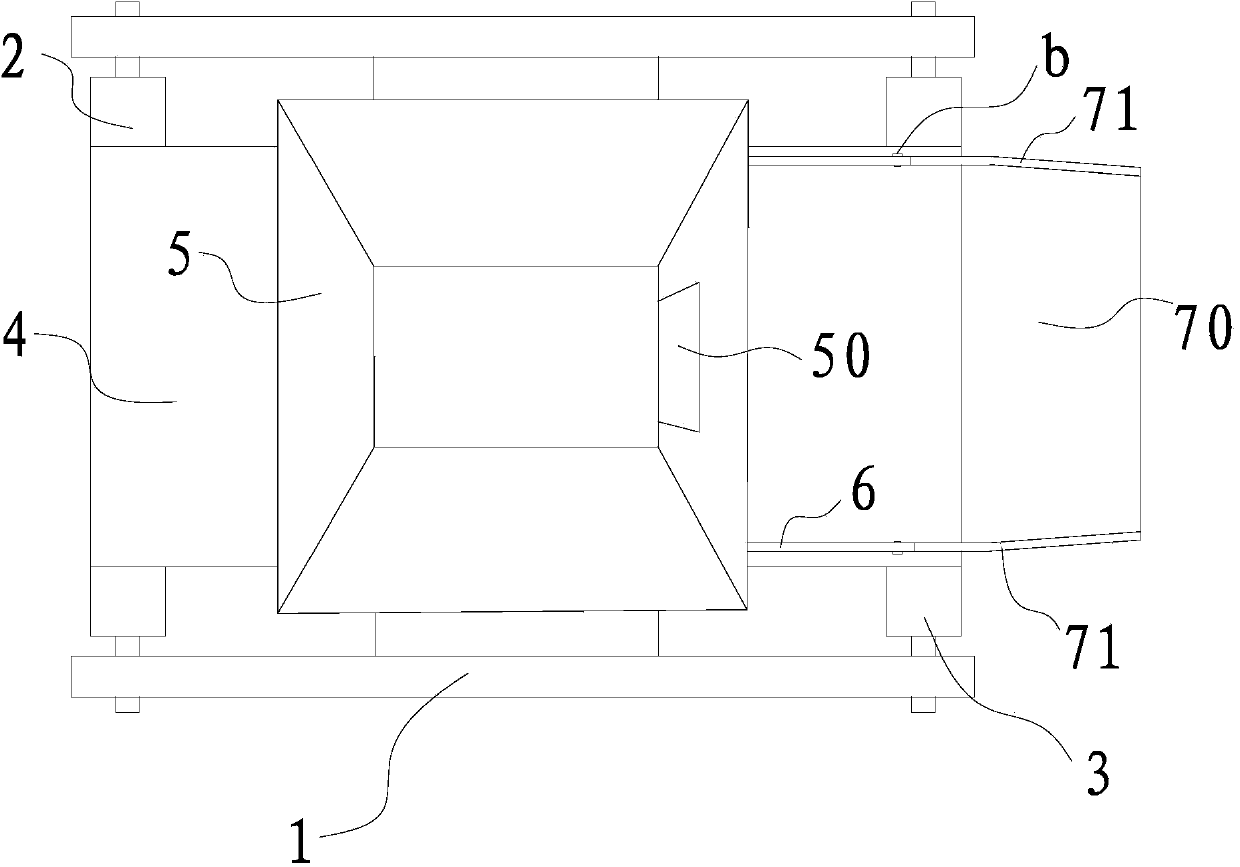

[0017] Such as figure 1 and figure 2 As shown, a material conveying device provided in this embodiment includes a first roller shaft 2 and a second roller shaft 3 that are respectively arranged at both ends of the frame 1 and can rotate around their own axes. The conveyor belt 4 on the first roller shaft 2 and the second roller shaft 3, and the driving mechanism (not shown) that drives the first roller shaft 2 or the second roller shaft 3 to rotate, meanwhile, the conveying device in this example also includes The hopper 5 arranged above the conveyor belt 4 between the first roller shaft 2 and the second roller shaft 3, along the conveying direction of the conveyor belt 4 and the baffle plates 6 arranged on both sides of the hopper 5, wherein the hopper 5 is arranged on On the frame 1, and the direction of the discharge port 50 of the hopper 5 is consistent with the conveying direction of the conveyor belt 4, the material retaining plate 6 is connected to both sides of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com