Industrialized mushroom production compost charging machine

A culture material, factory-like technology, applied in mushroom cultivation, cultivation, plant cultivation and other directions, can solve the problems of difficult to guarantee the quality of size and shape, serious spillage of culture material, high strength and other problems, to improve efficiency, uniform feeding, saving effect of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

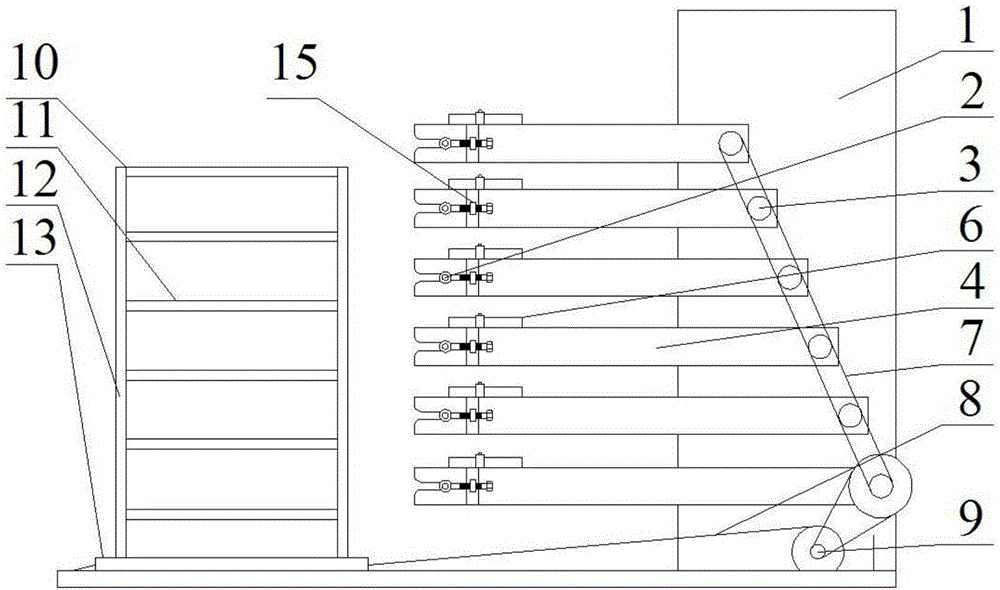

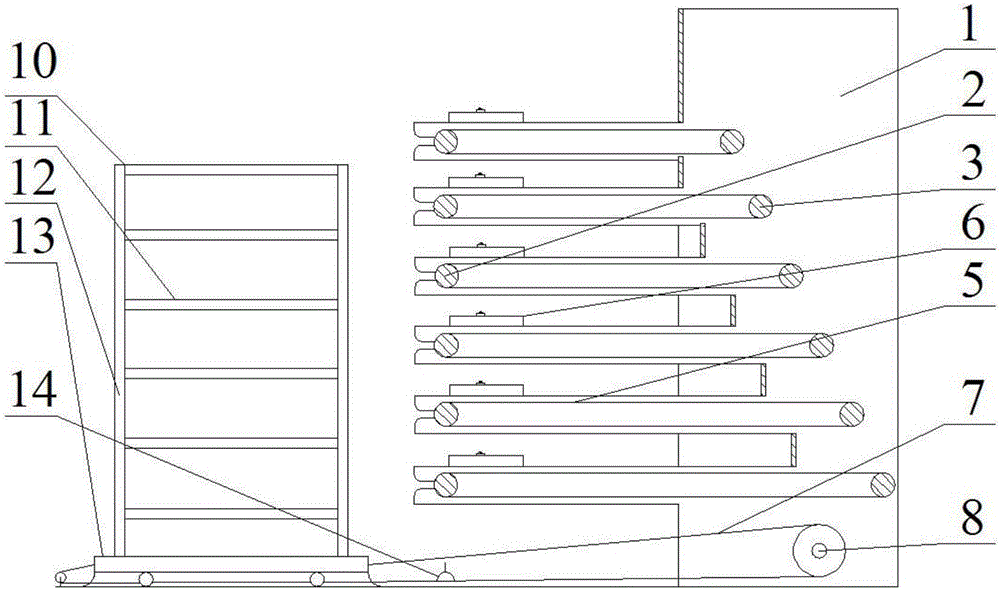

[0021] A feeding machine for culture material for industrialized mushroom production, including a silo, a transmission device, a culture frame, a culture frame pulley, and a power system; The layer spacing between the plates is the same as 45cm; the top of the silo is the feed port for the culture material, the width of the silo is 1m, and there are 6 identical rectangular discharge ports along the vertical direction on one side of the silo. The position of each discharge port It matches the corresponding culture tray; the transmission device includes a bracket, a driving roller, a driven roller, and a belt. Install a group of conveyor belts horizontally, the driven rollers of each group of conveyor belts are outside the silo and the distance from the outlet is 1m, and the driving rollers of each group of conveyor belts are inside the silo and the distance from the outlet is from top to bottom. Extended by 25cm; 3 diverters are installed side by side above the belt between the...

Embodiment 2

[0023] It is basically the same as Example 1, except that the cultivation frame is 4 layers, and the corresponding outlets and conveyor belts are all 4 groups; the diverter is installed at the outlet; the driving roller transmission is changed from chain transmission to gear rotation .

Embodiment 3

[0025] It is basically the same as in Example 1, except that the cultivation frame has 8 layers of corresponding outlets and 8 groups of conveyor belts; the transmission device of the pulley of the cultivation frame includes a pulley clutch, an oil pump, and a hydraulic cylinder, and the pulley clutch is set on the output of the motor. The end drives the oil pump to run, and the hydraulic cylinder is fixed at the bottom of the silo. The top of the hydraulic cylinder telescopic rod is connected to the front end of the cultivation frame block. The motor rotates through the block clutch to drive the oil pump to run. The hydraulic cylinder telescopic rod pulls the cultivation frame block forward and backward. Make the culture frame pulley placed on the ground and move back and forth horizontally between the outer side of the driven roller and the discharge port.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com