Flat gate valve

A flat gate valve and valve seat technology, applied in sliding valves, valve devices, engine components, etc., can solve the problems of leakage accidents, insufficient sealing between the valve seat and the valve body, etc., to reduce leakage accidents, simple structure and strong sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

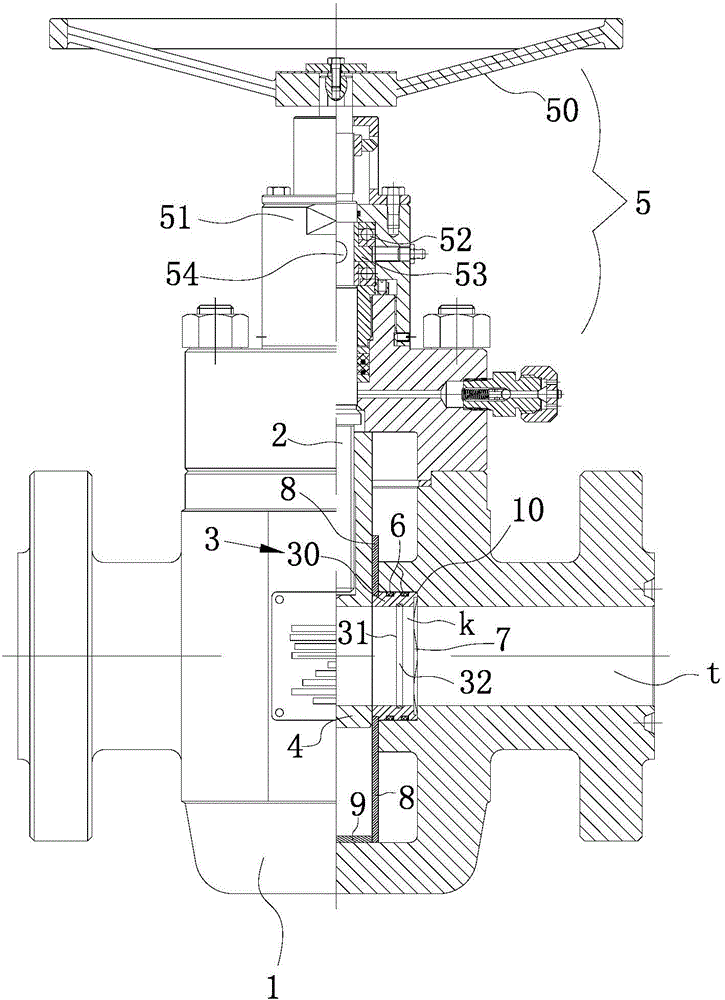

[0022] Such as figure 1 As shown, the slab gate valve of this embodiment includes a valve body 1, a valve stem 2, a valve seat 3 that is sealed with the channel openings 10 on both sides of the valve body 1, is located between the valve seats 3 on both sides and is arranged on the valve body. The valve plate 4 on the rod 2, and the driving mechanism 5 for driving the valve rod 2 to rotate around its own axis so that the valve plate 4 moves up and down to block or open the channel, wherein the valve rod 2 and the valve plate 4 constitute a screw nut structure.

[0023] Specifically, the valve seat 3 includes a seat body 30 with a through hole k communicating with the channel t, an installation groove 31 disposed inside the seat body 30 around its circumference, and arranged in the installation groove 31 so that the valve seat 3 and the channel There is a tightening ring 32 with a tendency to tighten at the junction of the mouth 10.

[0024] Further, the outer circumference of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com