Manufacturing method for hot-stamped and transferred film with Fresnel lens visual effect

A technology of Fresnel lens and visual effects, which is applied in the direction of printing, printing, and printing devices for producing special types of printed matter, and can solve problems such as affecting printing processing, high cost, and losing a large number of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described,

[0020] The manufacturing method of the hot stamping and transfer film with Fresnel lens visual effect comprises the following steps:

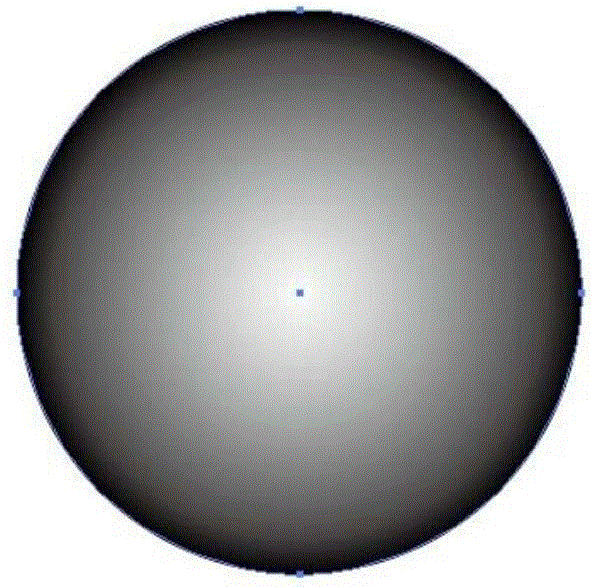

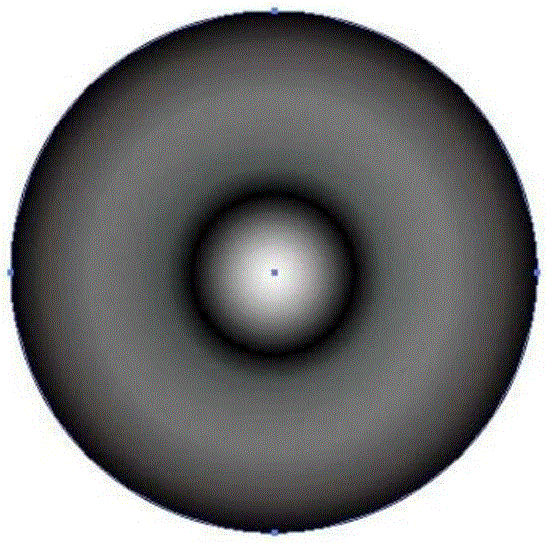

[0021] Step 1: Make a gray scale pattern of the lens, and make a gray scale pattern of the lens according to the required diameter, which can be a convex lens, a concave lens or a rippling lens with a combination of concave and convex, such as figure 1 As shown, it is a convex lens, if figure 1 The grayscale in reverse, then it is a concave lens, figure 2 Shown is a rippling lens with a convex lens at the very center of the rippling lens. The different gray scales of each ring of the lens gray scale pattern represent a jagged shape with different angles but the same depth. The lower the gray scale, the whiter it represents the convex effect of the curved surface after the light is refracted, like a convex lens. fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com