Day-night dual-purpose zoom lens capable of eliminating heat difference

A zoom lens and adiabatic technology, which is applied in the field of optical lenses, can solve the problems of the overall weight of the lens and its cost reduction, the impact of the reduction is not significant, and the number of lenses is large, so as to achieve the effects of improving competitiveness, reducing production costs, and stabilizing analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

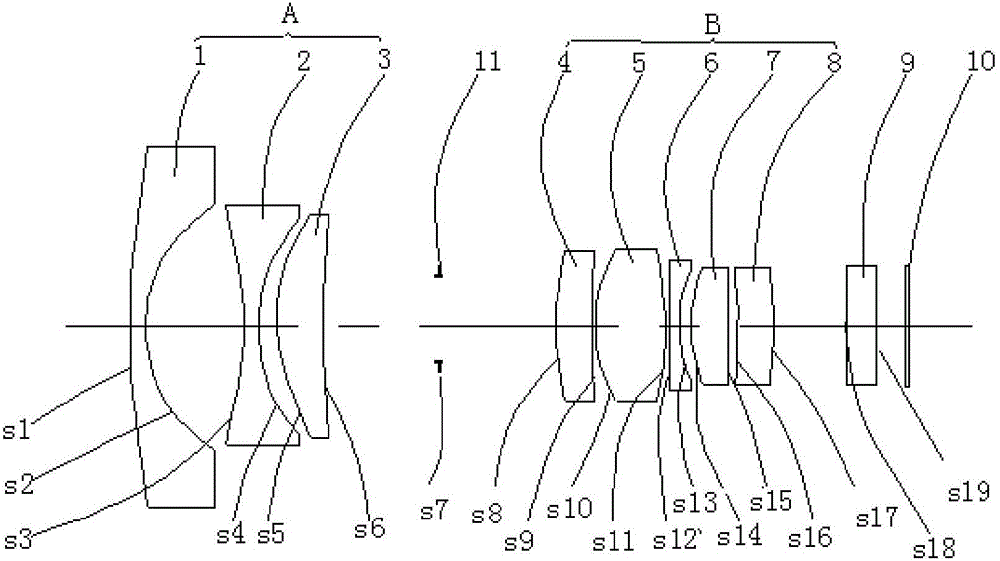

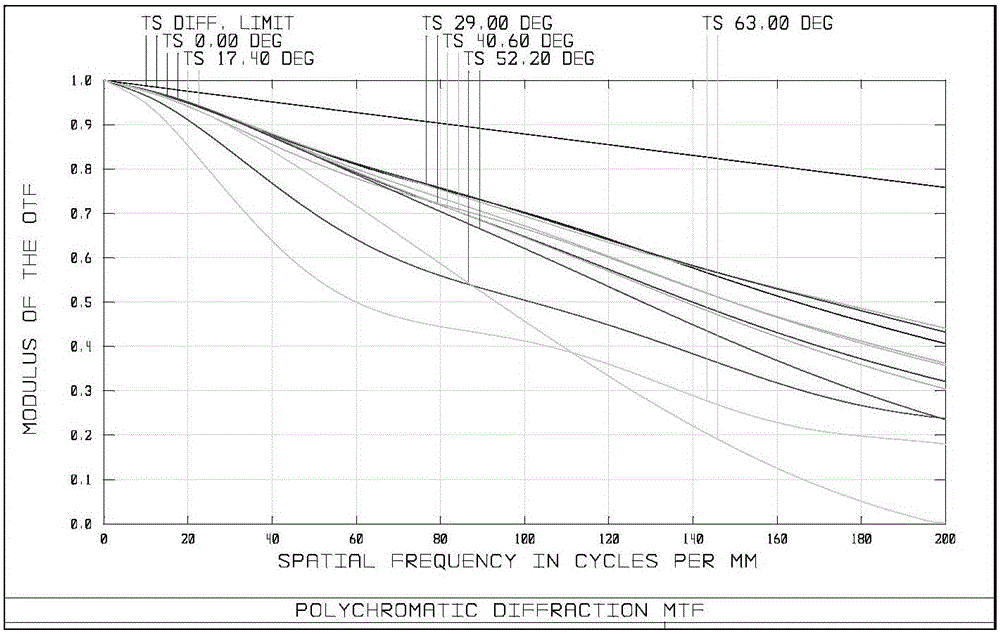

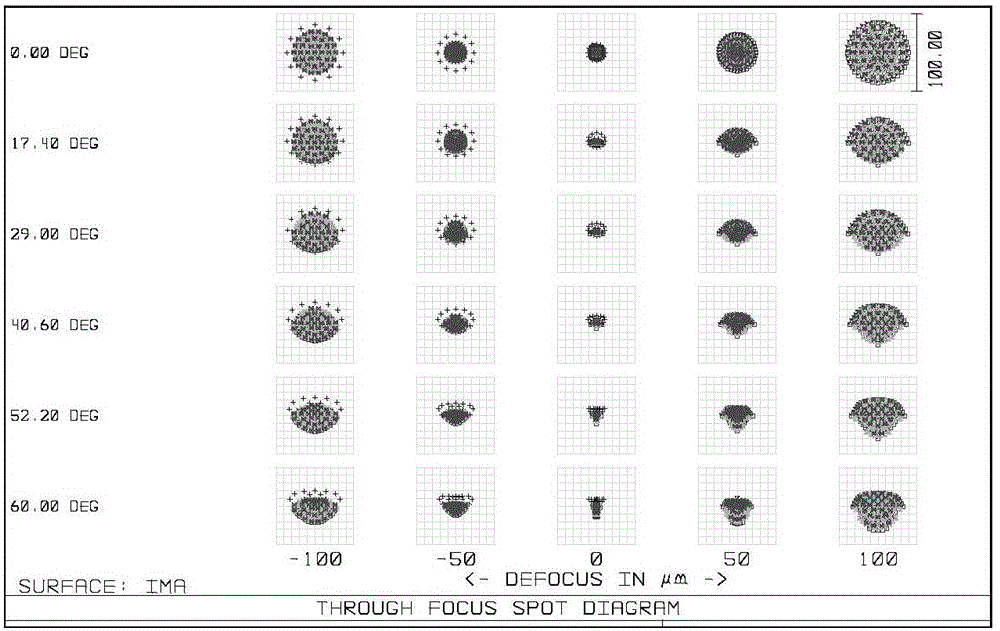

[0089] like Figure 2 to Figure 11 As shown, the focal length of each lens in the first embodiment is shown in the following table:

[0090] f1

f3

f6

f45

f78

fa

fb

|fb / fa|

f1 / f3

f45 / f78

f6 / fb

-15.32

17.87

-12.65

9.11

15.65

-9.06

10.39

1.14

-0.85

0.58

-1.21

[0091] The thickness, material and surface R value of each lens in the first embodiment are shown in the following table:

[0092]

R value

thickness

Material

S1

50

0.77

1.62,60

S2

7.965

5.14

S3

-21.327

0.77

1.62,60

S4

9.55

0.89

S5

11.394

2.42

1.75,27

S6

63.51

d6

S7

infinity

d7

S8

13.745

1.925

1.53,55

S9

51.174

0.11

S10

8.361

3.66

1.49,81

S11

-15.136

0.15

S12

-538...

Embodiment approach 2

[0100] like Figure 12 to Figure 21 As shown, the focal length of each lens in the second embodiment is shown in the following table:

[0101] f1

f3

f6

f45

f78

fa

fb

|fb / fa|

f1 / f3

f45 / f78

f6 / fb

-23.22

34.92

-11.51

10.06

13.76

-10.69

11.48

1.07

-0.66

0.73

-1

[0102] The thickness, material and surface R value of each lens in the second embodiment are shown in the following table:

[0103]

R value

thickness

Material

S1

38

0.76

1.62,60

S2

10.3981

5.9

S3

-22.2041

0.913

1.62,60

S4

12.9939

3.24

S5

20.79

3.46

1.85,23

S6

63.181

d6

S7

infinity

d7

S8

9.986

1.925

1.53,55

S9

46.91

0.11

S10

8.84

2.804

1.49,81

S11

-88.09

0.11

S12

...

Embodiment approach 3

[0111] like Figure 22 to Figure 31 As shown, the focal length of each lens in the third embodiment is shown in the following table:

[0112] f1

f3

f6

f45

f78

fa

fb

|fb / fa|

f1 / f3

f45 / f78

f6 / fb

-14.6

22.04

-9.7

9.8

9.44

-8.85

10.39

1.17

-0.66

1.038

-0.93

[0113] The thickness, material and surface R value of each lens in the third embodiment are shown in the following table:

[0114]

R value

thickness

Material

S1

97.79

0.77

1.62,60

S2

8.296

4.71

S3

-35.257

0.74

1.65,56

S4

9.88

1.48

S5

12.54

1.67

1.85,23

S6

35.16

d6

S7

infinity

d7

S8

10.48

2.49

1.49,81

S9

-25.234

0.087

S10

10.7

3.41

1.53,55

S11

37.19

0.54

S12

-40.26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com