Design method for dust removing prompt of PCBA

A dust and user technology, applied in the design field of PCBA dust removal reminder, can solve problems such as adverse consequences, circuit board damage, board burnout, etc., to achieve the effect of improving user satisfaction and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings:

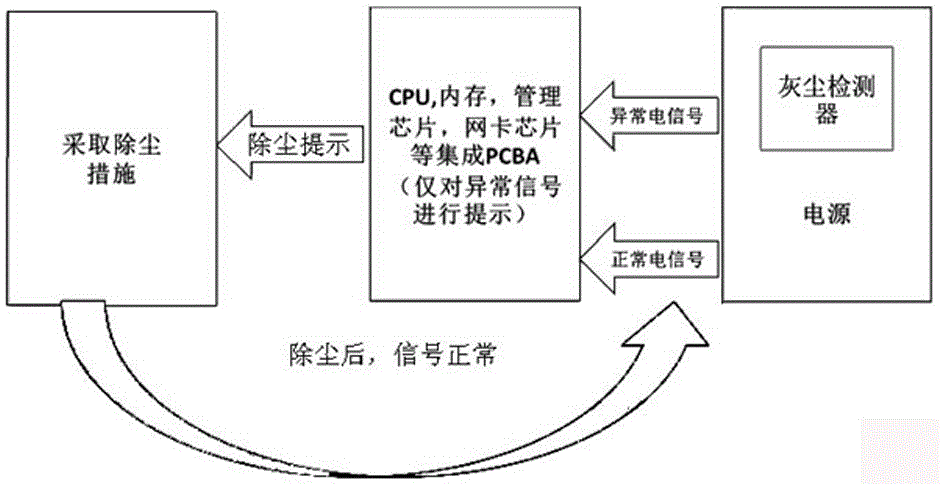

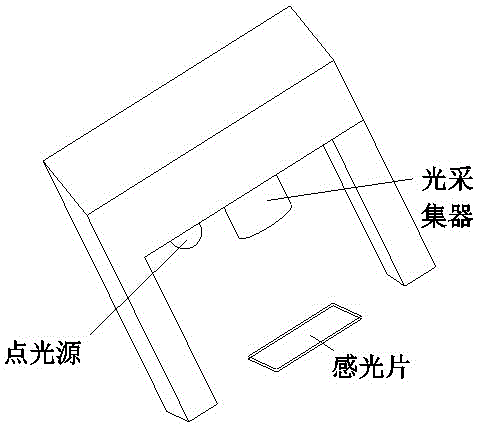

[0019] like figure 1 Shown: When designing the PCB layout, the space for the dust detector should be taken into consideration and reserved, and the power supply and software design of the detector should also be considered. The light collector includes a photosensitive sensor; when the reflected light received by the light collector of the dust detector is weak to a certain extent, the resistance of the photosensitive resistor is large, and the electrical signal output to the system management chip is weak. Limit value, the system management chip sends a prompt signal or reminds the user to remove dust on the screen or by implementing lights and sounds. When removing dust, the photosensitive sheet and other devices should also be cleaned. After the dust is rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com