Drainage hidden type metal tile and metal tile machining die

A technology for processing molds and metal tiles, which is applied in the field of drainage hidden metal tiles and metal tile processing molds, which can solve the problems of affecting the aesthetics of buildings, falling icicles, and the impact of pedestrians, achieving better collection effects and convenient demoulding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

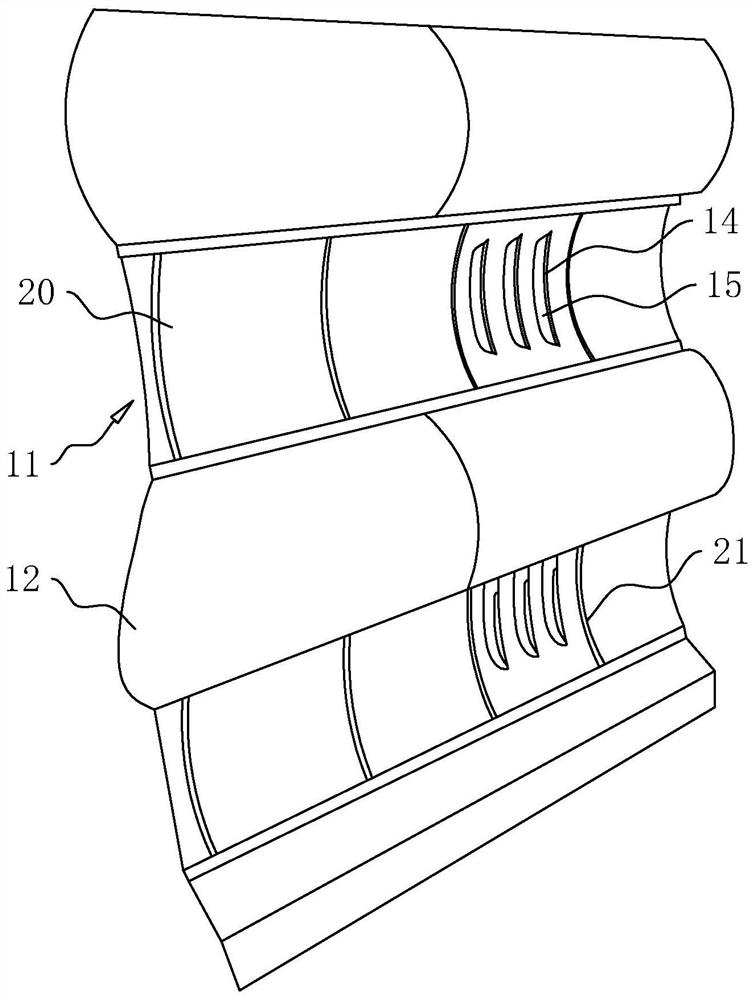

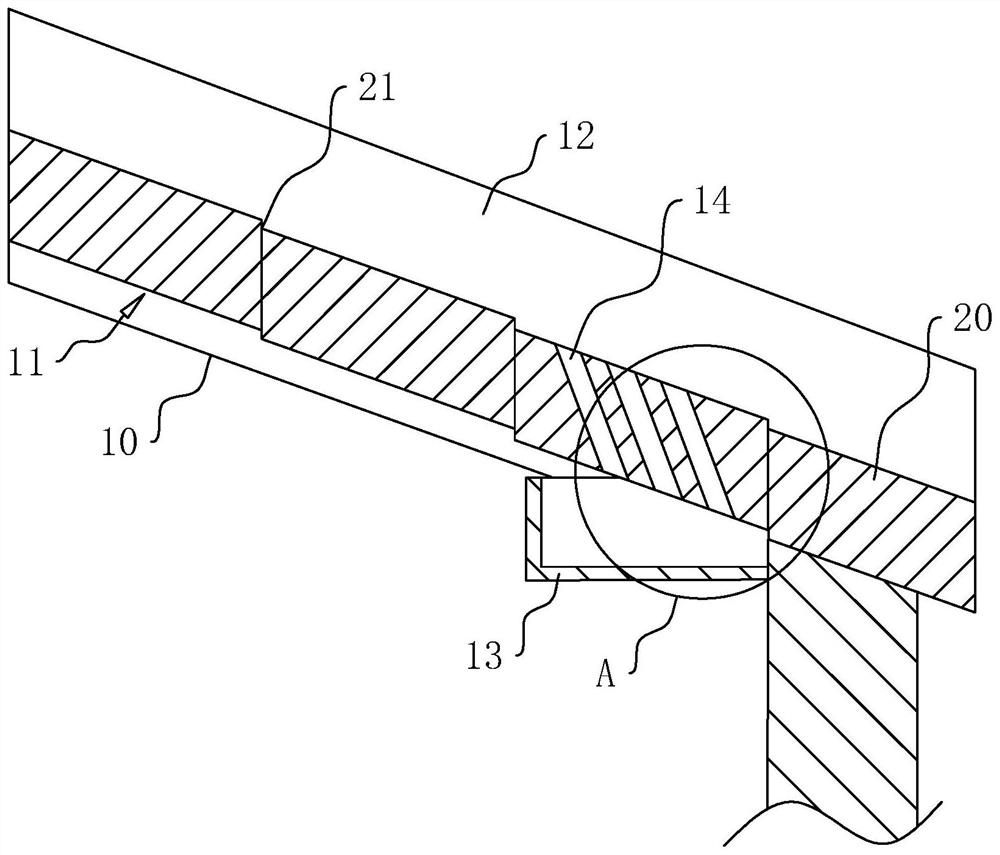

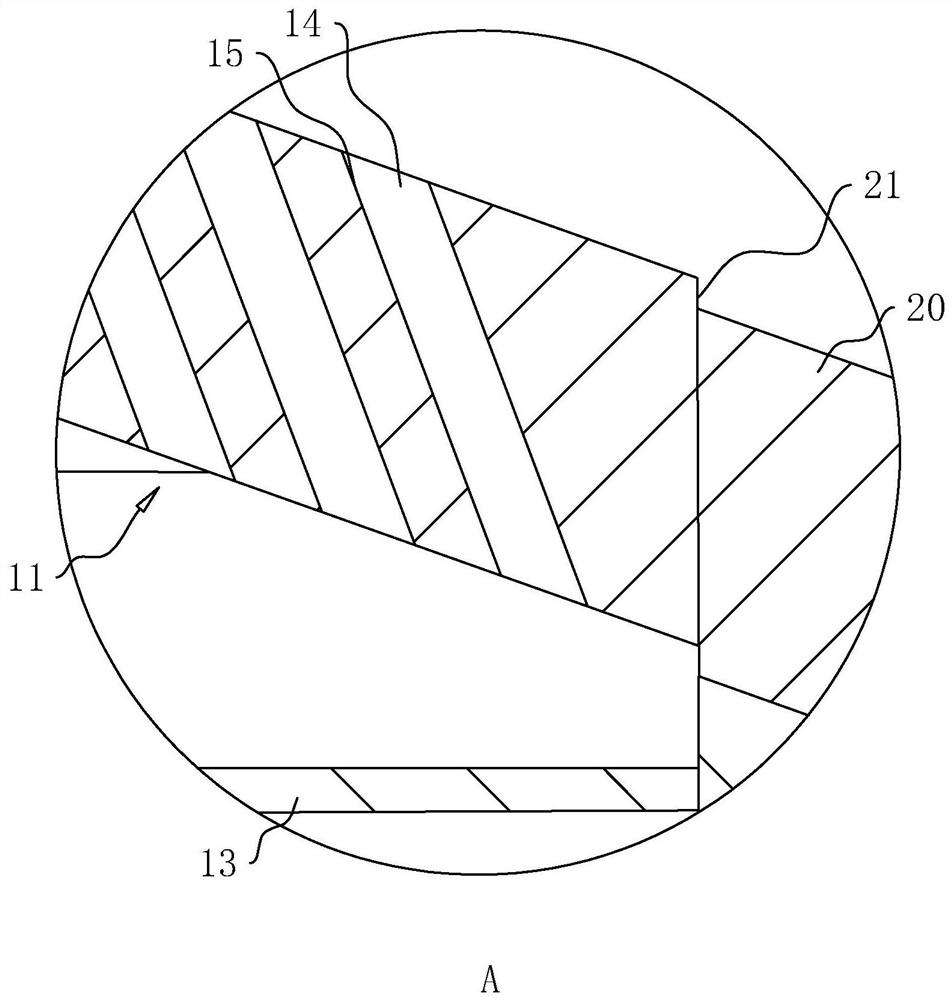

[0038] Embodiment 1: refer to figure 1 and figure 2 , comprising a pre-paved keel frame 10, on which a bottom tile 11 and a cover tile 12 are laid to form a slope. Bottom tiles 11 and cover tiles 12 are arranged alternately, and several groups are arranged along the direction of the keel frame 10 . The bottom tile 11 is lower than the cover tile 12 and is used to guide rainwater from the bottom of the slope. The bottom tile 11 is provided with a drainage groove 14, and the keel frame 10 is provided with an underground ditch 13. The bottom of the drainage groove 14 is projected vertically in the underground ditch 13, and is used to guide the rainwater on the bottom tile 11 into the underground ditch 13.

[0039] When rainwater dripped, because the bottom tile 11 upper surface was concave from both sides to the middle part, the rainwater flowed downward along the slope into the drainage groove 14, and then flowed into the dark ditch 13 from the drainage groove 14, and finally...

Embodiment 2

[0045] The difference between embodiment 2 and embodiment 1 is: refer to Figure 4 , in order to improve the water guiding effect, the bottom tile 11 is fixedly equipped with a water retaining part 30, and there are several water retaining parts 30, which are respectively located at the side of the drainage groove 14 near the lower end of the slope. The water blocking portion 30 forms a blocking surface 31 near the upper end of the slope, and the blocking surface 31 is perpendicular to the position where it is connected to the bottom tile 11 .

[0046] The implementation principle of a water-conducting metal tile in the embodiment of the present application is as follows: when the amount of rainwater is large, the rainwater flows down through the slope, and when it reaches the notch of the drainage groove 14, due to inertia, it continues to impact downward, and when the drainage groove 14 is close to the slope A water retaining part 30 is arranged on one side of the lower end ...

Embodiment 3

[0048] The difference between embodiment 3 and embodiment 1 is: refer to Figure 5 , similarly, in order to improve the water guiding effect, a water storage part 40 is fixedly installed on the bottom tile 11, the water storage part 40 is located on the side of the bottom tile 11 inclined downward, and the upper surface of the water storage part 40 is concave, and it is along the horizontal direction Incline upwards to form a water storage area 41 for temporary water storage. In order to achieve the effect of drainage, the upper end of the water storage part 40 is higher than the drainage groove 14 located at the lowermost end.

[0049] The implementation principle of a water-conducting metal tile in the embodiment of the present application is as follows: when the rainfall is too large and the drainage tank 14 cannot be completely discharged, part of the rainwater is left along the slope, first accumulated in the water storage part 40, and when the water storage part 40 When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com