Digital print making Filin direct printing and digital proofing output system

A technology of digital printing and digital proofing, which is applied in the field of comprehensive digital printing and plate making, can solve the problems of high price, barriers to popularization in the market, and inability to use interoperability, etc., to improve edge resolution, save mechanical parts, and improve image output quality perfect and clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

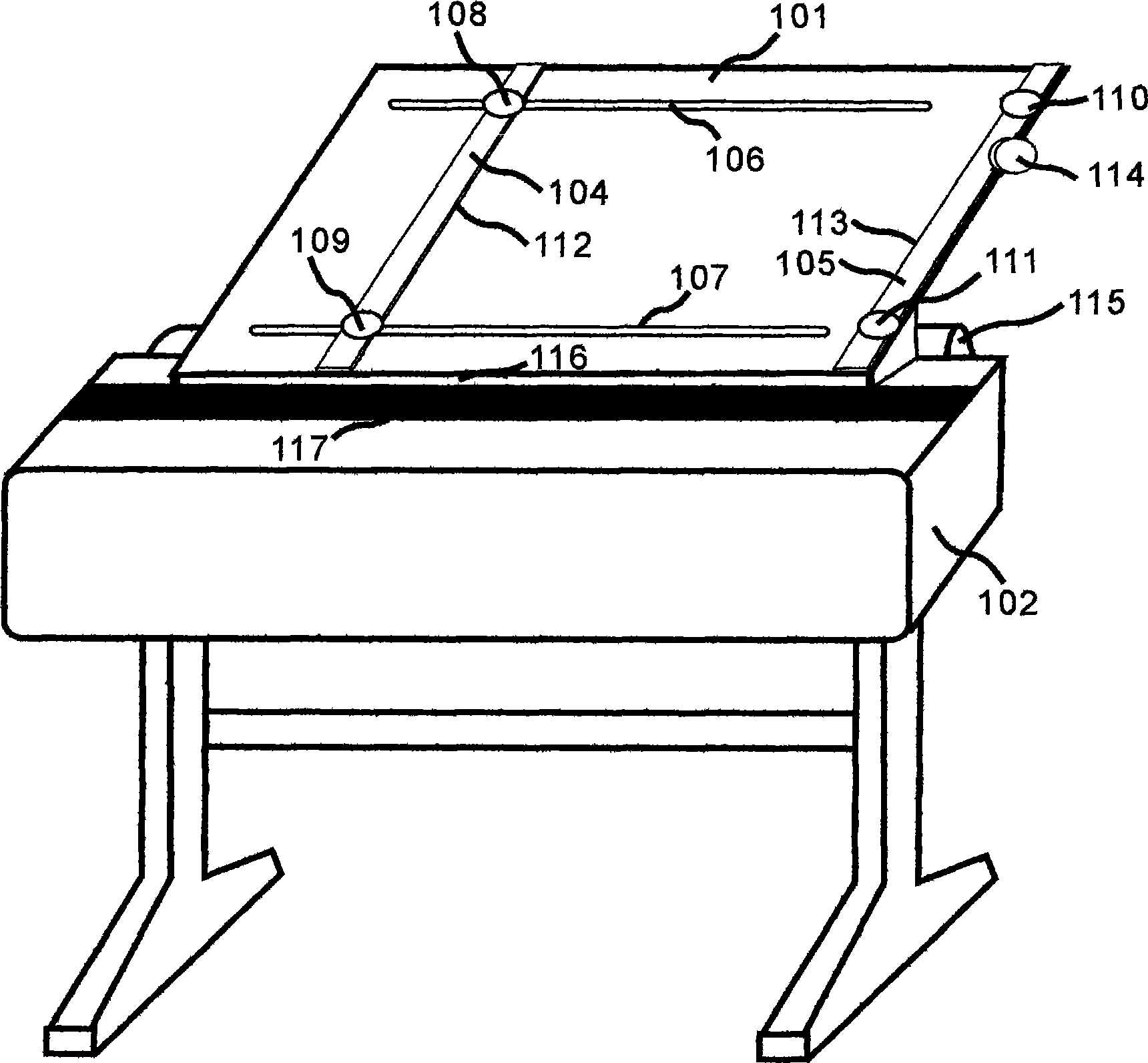

[0019] The invention provides a high-resolution inkjet printer for digital printing plate making, film direct printing and digital proofing output system, which realizes computer digital printing through high-precision control platform, high-resolution inkjet printer and computer image processing software. All functions of plate making, computer digital film output and digital printing proof output. It is a comprehensive multi-purpose pre-press output system that realizes the trinity of plate making, film making and digital proofing through inkjet printers.

[0020] Describe the embodiment of the present invention in detail below by relevant diagram: figure 1 The overall hardware diagram of the direct printing and digital proofing output system for digital printing plate-making film. Among them, 102 is the main part of the printer, which is an inkjet printer that supports high resolution and can realize flat printing through modification or naturally, and 117 is the printing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com