Substrate inspection method and apparatus

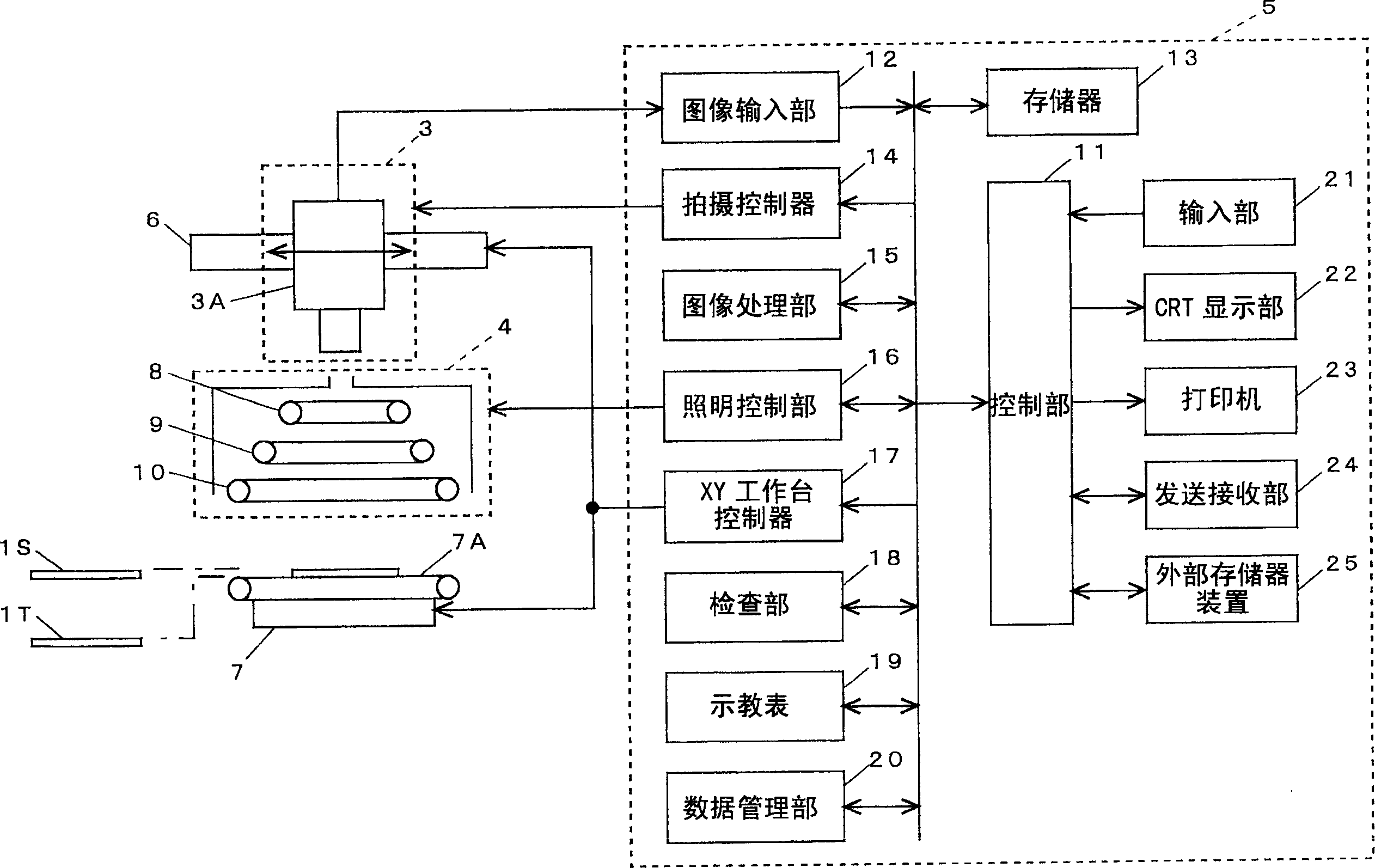

A substrate inspection and substrate technology, applied to measuring devices, material analysis through optical means, instruments, etc., can solve problems such as problems in the setting of inspection areas, increased costs, and errors in drive parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

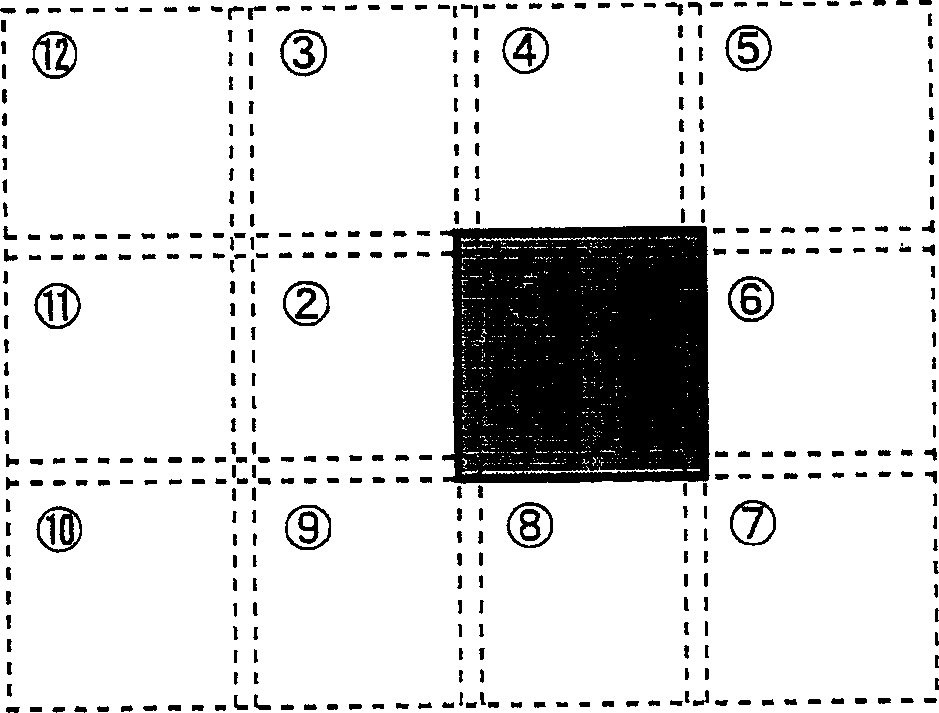

[0106] In this embodiment, after the above-mentioned reference substrate 1S is divided into a plurality of regions and photographed, the images of each region are concatenated to create and register an overall image of the reference substrate 1S. In addition, between adjacent areas, an overlap of a predetermined number of pixels is set according to an error (hereinafter referred to as "mechanical error") generated by the movement amount of the X-axis table 6 and the Y-axis table 7 . For each of these images, pattern matching processing using image information of overlapping portions is performed, and corresponding pixels are overlapped after adjusting the correspondence relationship of pixels based on the matching results to create an appropriate overall image.

[0107] image 3 An example of image superimposition processing is shown, and the order of connection is indicated by a circled number. image 3 In the example of , the image in the center is taken as the first image,...

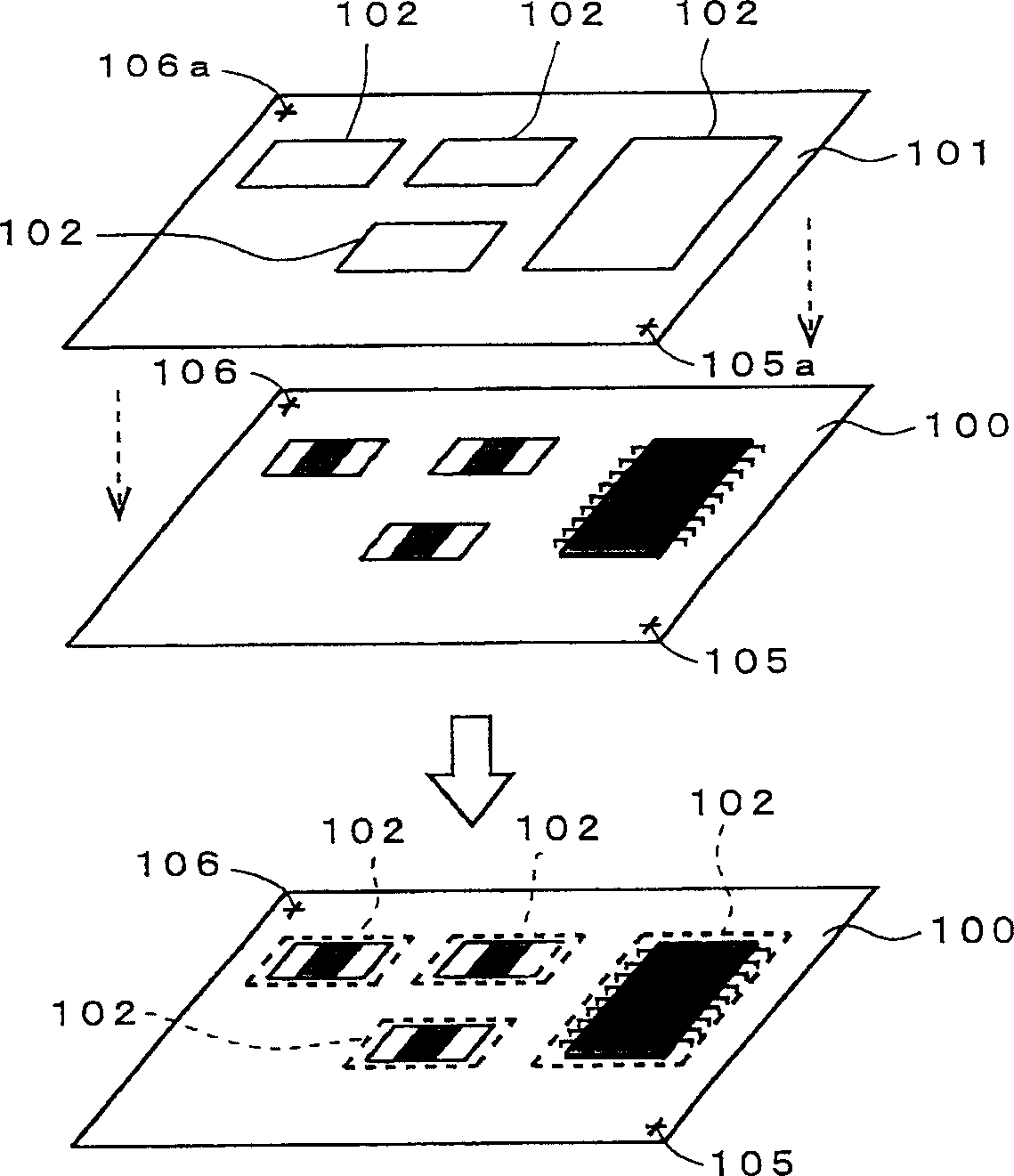

Embodiment 2

[0140] In each of the following embodiments of this second embodiment, the welding part (fillet weld) of the inspection part is taken as a premise, and the imaging target area, the setting method of the inspection area, and the relationship between the processing target image and the imaging target area are described more specifically. The detection method of deviation, etc.

[0141] According to the above figure 1 Since the colored lights from the light sources 8, 9, and 10 of the light projecting part 4 are directly projected and reflected on the surface of the fillet weld, red, green, and blue colors can be obtained corresponding to the inclination of the fillet weld. An image distributed at a prescribed scale. In the inspection of the fillet weld, by extracting these colors separately, and comparing their position and area with the judgment reference value, it is possible to judge whether the inclination state is good or not.

[0142] Figure 10 It is an image showing t...

Embodiment 3

[0165] In the above-mentioned embodiment 2, it is assumed that the portion to be inspected on the substrate is included in any image constituting the overall image, but if Figure 15 As shown, there is a case where a component 56 (the component shown in the figure is a QFP) to be inspected straddles between images. In such a case, as in the first embodiment, it is preferable to set an imaging target area at an arbitrary position on the overall image 103 .

[0166] In Example 3, after the overall image 103 of the reference substrate 1S is created, the imaging target area 57 is set so that the entire part 56 is included in the image 103, the set position is registered, and the image in the imaging target area 57 is cut out. , and register as the reference image.

[0167] In addition, the setting of the imaging target area 57 can be performed using the image image of the above-mentioned board, but it is not limited thereto. can be set.

[0168] Also, there is no doubt that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com