Product packaging surface defect detection and classification method based on machine vision

A technology of product packaging and machine vision, applied to instruments, image analysis, computer parts, etc., can solve problems such as difficult detection of color-related defects, unsatisfactory detection, loss of color information, etc., to improve the detection effect and avoid artificial Effects of factor interference and improvement of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

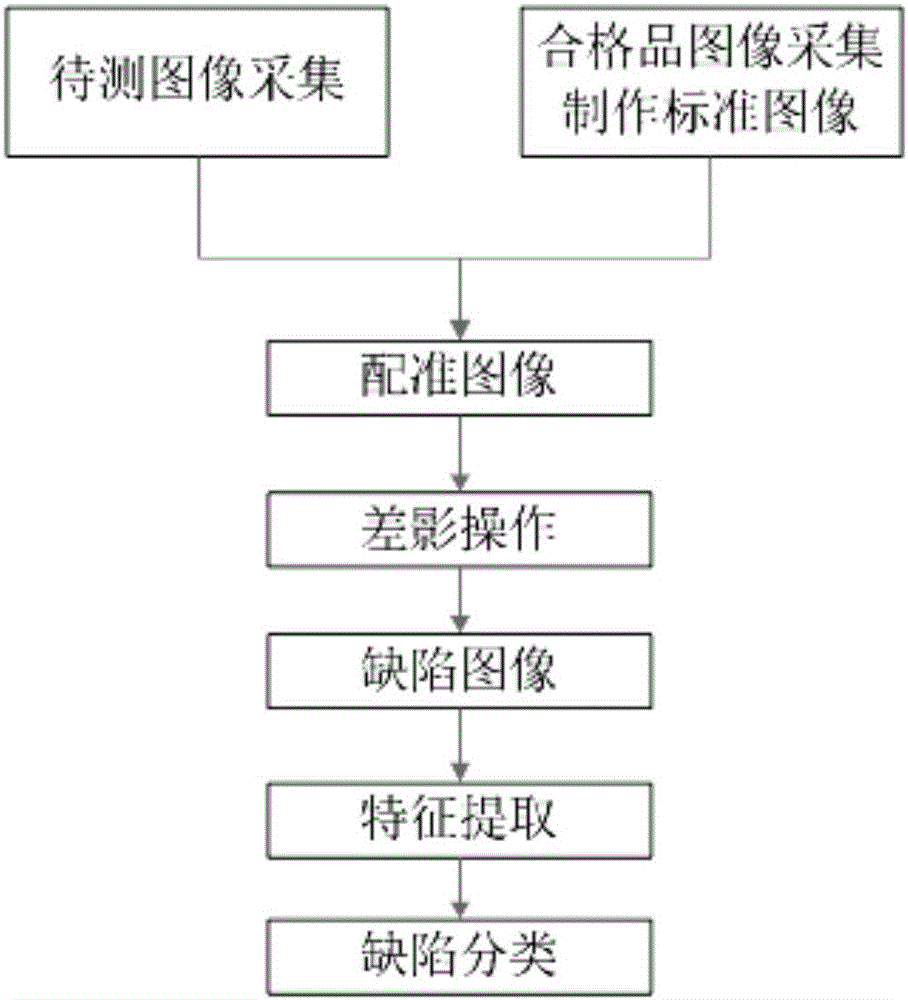

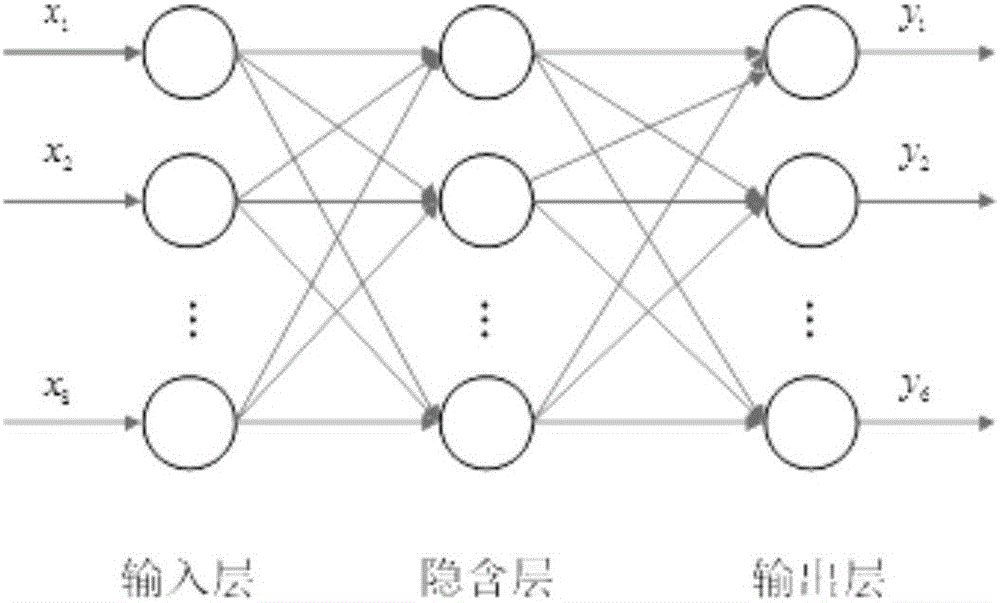

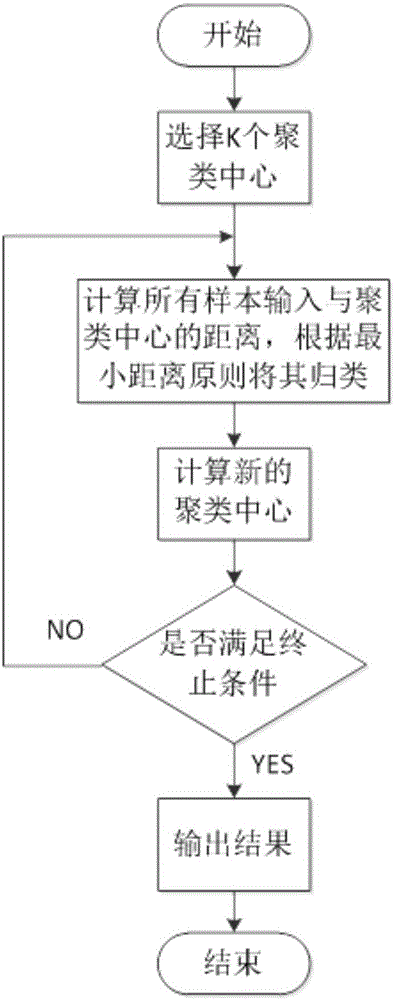

[0032] Embodiment 1: A method for detecting and classifying surface defects of product packaging based on machine vision, specifically comprising the following steps:

[0033] (1) Use a high-definition, high-speed camera to collect multiple high-definition color images of non-defective product packaging, and use the statistical averaging method to synthesize a standard image; then use the camera to shoot in real time, and collect high-definition color images of the product packaging to be tested online as the image to be tested ;

[0034] The statistical average method is to calculate the statistical average value as the template value according to the probability distribution of the pixel values of each sample. Assuming that the collected sample images are N pieces, each sample image is expressed as: f i (x, y), i=0, 1, L N-1, then each pixel value on the template is:

[0035] (2) Register the image to be tested with the standard image based on the SURF algorithm. The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com