Fe-N-C oxygen reduction catalyst and synthesizing method and application thereof

A synthesis method and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve the effects of reduced production costs, low prices, and simple synthesis processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

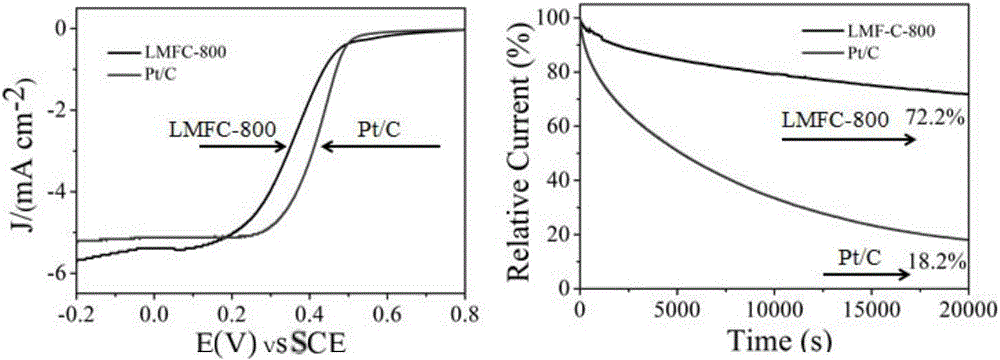

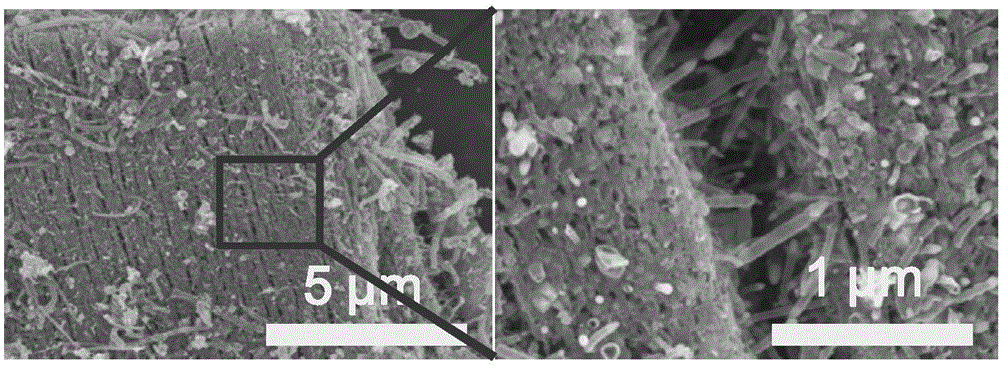

[0030] 2g melamine, 4g oxalic acid, 1g Fe(NO 3 ) 3 9H 2 O was added to 50ml of water, stirred and refluxed in an oil bath at 80°C for 6h. After mixing evenly, the mixture was suction filtered and dried in air at 70°C. in N 2 Calcined in a muffle furnace at 800 °C under the protection of atmosphere. The calcined samples were ground and placed in 0.5M H 2 SO 4 Medium treatment for 9h to remove easily soluble Fe components. Suction filter the product after acid removal, wash with deionized water several times, and dry in air to obtain Fe-N-C composite.

[0031] Weigh 0.008g of Fe-N-C complex, dissolve it in a mixed solution of 5% Nafion (perfluorosulfonic acid) and ethanol at a volume ratio of 10:1, mix evenly by ultrasonic, use a platinum sheet as a counter electrode, and a calomel electrode as a reference electrode Test material in 0.1M HClO 4 ORR activity in . The onset potential of ORR is 0.472V (VS.SCE), and the limiting current density is 5.5mAcm -2 .

[0032] ...

Embodiment 2

[0034] 3g dicyandiamide, 4g oxalic acid, 0.7g FeCl 3 ·6H 2 O was added to 50ml of water, stirred and refluxed in an oil bath at 80°C for 6h. After mixing evenly, the mixture was filtered and dried in air at 70°C. in N 2 Calcined in a muffle furnace at 900°C under atmosphere protection. The calcined samples were ground and placed in 0.5M H 2 SO 4 Medium treatment for 9h to remove easily soluble Fe components. The product after acid removal is suction filtered, washed with deionized water several times, and dried in air.

[0035] The obtained Fe-N-C complex, 5% Nafion and ethanol were mixed in a certain proportion and then ultrasonically mixed evenly. The platinum sheet was used as the counter electrode, and the calomel electrode was used as the reference electrode. The test material was in 0.1M HClO 4 ORR activity in . The onset potential of ORR is 0.46V0(VS.SCE), and the limiting current density is 5.4mA.cm -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting current density | aaaaa | aaaaa |

| Limiting current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com