Production method of high-reinforcement modified anhydrous calcium sulfate crystal whiskers

A technology of anhydrous calcium sulfate and production methods, applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of high production cost, difficult industrialization, complicated production process, etc., and achieve low production cost and hydrophobicity Excellent and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

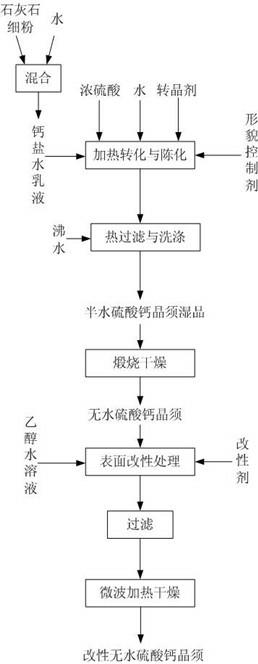

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of calcium brine emulsion: Add 25g of limestone powder into 50g of water under stirring, and continue to stir for 20 minutes to prepare a calcium brine emulsion; the CaCO of the limestone used in this step 3 The content is 98%, the crushing fineness of limestone is 325 mesh, and the molar mass of limestone powder is 0.25mol.

[0037] (2) Preparation of sulfuric acid aqueous solution: Add 26.6ml of concentrated sulfuric acid with a concentration of 98% in 440ml of water under the stirring condition of 83 rpm to prepare a sulfuric acid aqueous solution with a sulfuric acid concentration of 10%, and then add 0.088mol of acetic acid; The crystal transformation agent used in the invention has formic acid, acetic acid or propionic acid, preferably acetic acid in the present embodiment.

[0038] (3) Conversion reaction, aging, filtration and washing:

[0039] The first is conversion reaction and aging. Heat the sulfuric acid aqueous solution in step (2) to in...

Embodiment 2

[0049] Except that the surface modifier is Tween-60, and the consumption is 1.5% of the anhydrous calcium sulfate whisker weight, other conditions are the same as in Example 1. The activation index of the finally obtained modified anhydrous calcium sulfate whiskers was 58.2%.

Embodiment 3

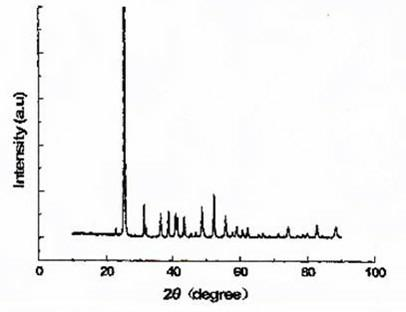

[0051] Except that the aging time was 2 hours, other conditions were the same as in Example 1. The obtained anhydrous calcium sulfate whisker has a loose appearance, its XRD spectrum is consistent with PDF card number 37-1496, and the average aspect ratio is greater than 50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com