Preparation method for BiOCl photocatalyst with controllable morphology and crystal face

A photocatalyst, crystal face technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of high pH, harsh reaction conditions, long reaction time, etc. Simple, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The first step is to accurately weigh three parts of Bi(NO 3 ) 3 ·5H 2 O was added to 30mL of deionized water, ethanol or dimethylformamide solvent respectively, stirred for 10min until uniform, and obtained

[0024] Three mixtures containing bismuth, numbered A, B, C respectively;

[0025] In the second step, add 11.5 mmol of 1-butyl-3-methylimidazole chloride to A, B, and C respectively, stir for 10 minutes and mix well to obtain a white mixed solution;

[0026] In the third step, put the three parts of the white mixture obtained in the second step into a KQ-100 ultrasonic cleaner for 10 min, and adjust the reaction temperature to 30°C;

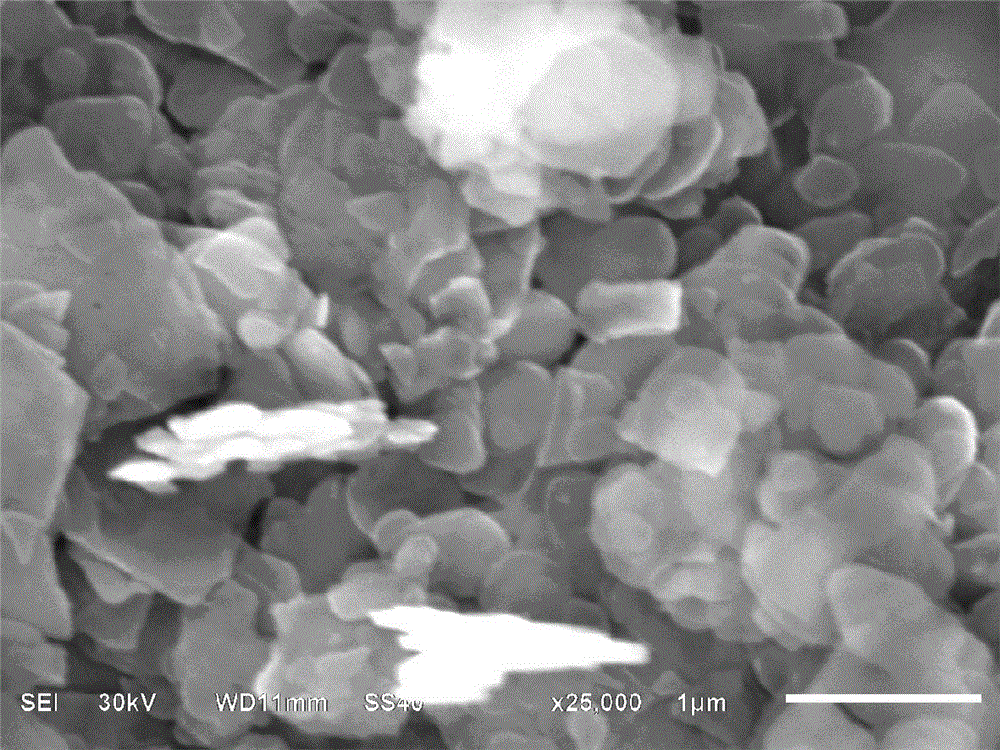

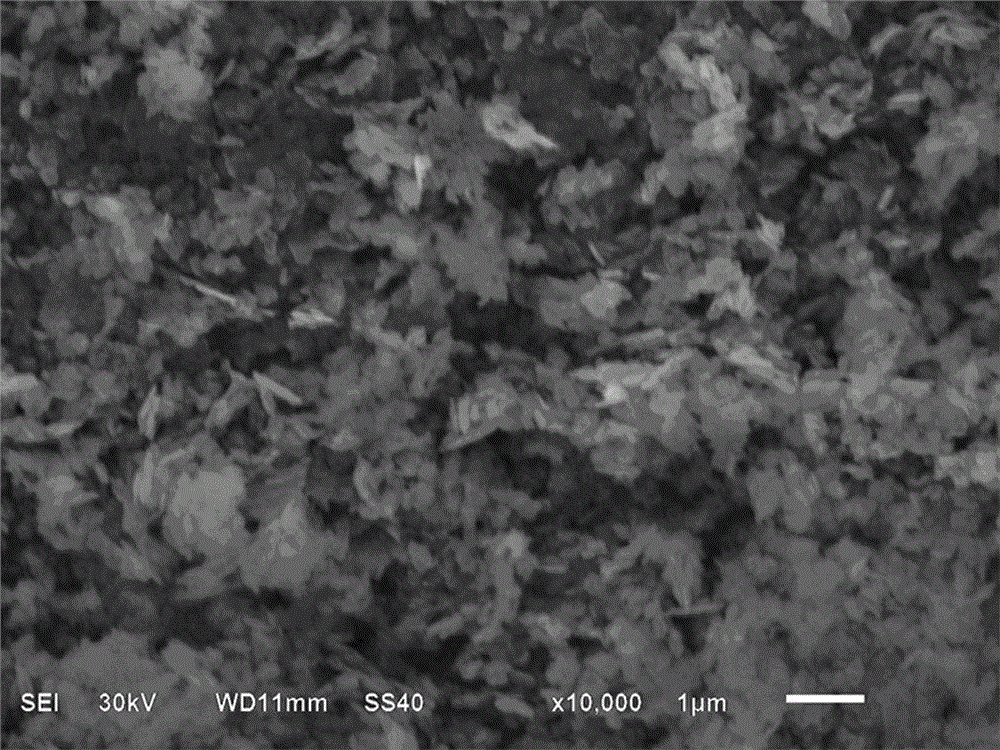

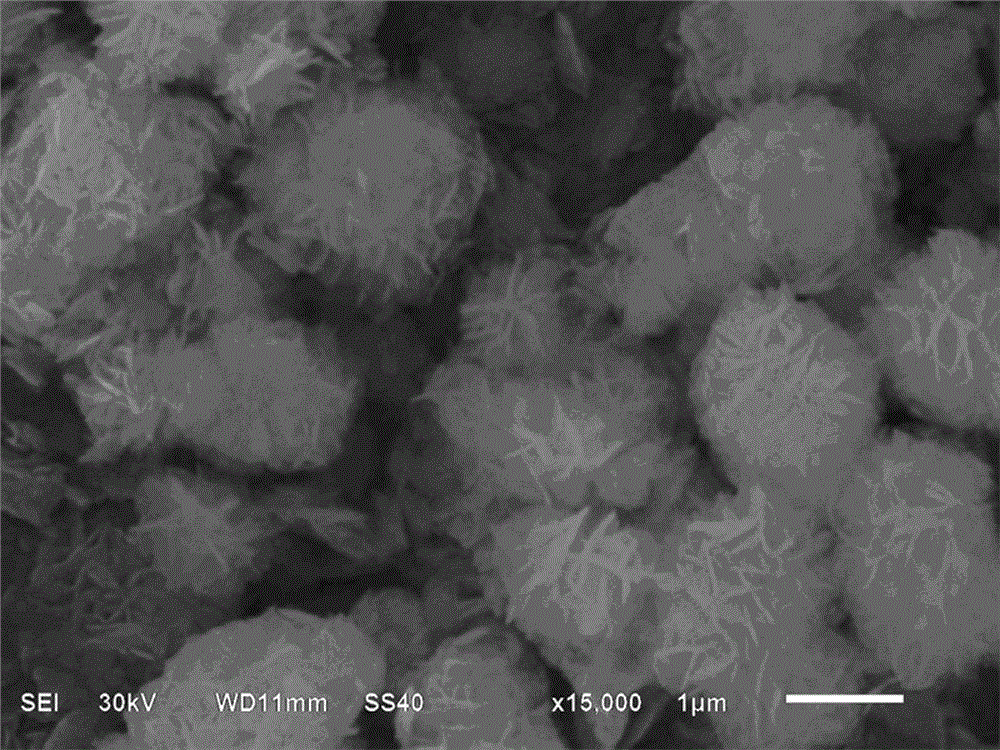

[0027] In the fourth step, the three mixed solutions were centrifuged after ultrasonication, and the obtained precipitates were alternately washed three times with deionized water and ethanol, and then vacuum-dried at 60° C. for 24 hours to obtain BiOCl photocatalyst powders with different shapes.

Embodiment 2

[0029] The first step is to accurately weigh three parts of Bi(NO 3 ) 3 ·5H 2 O was added to 20mL of deionized water, ethanol or dimethylformamide solvent, and stirred for 10min until uniform, and three parts of bismuth-containing mixed solutions were obtained, respectively numbered as A, B, and C;

[0030] In the second step, add 10 mmol of 1-butyl-3-methylimidazole chloride to A, B, and C respectively, stir for 10 minutes and mix well to obtain a white mixed solution;

[0031] In the third step, put the three white mixtures obtained in the second step into a KQ-100 ultrasonic cleaner for 20 min, and adjust the reaction temperature to 25°C;

[0032] In the fourth step, the three mixed solutions were centrifuged after ultrasonication, and the obtained precipitates were alternately washed three times with deionized water and ethanol, and then vacuum-dried at 60° C. for 24 hours to obtain BiOCl photocatalyst powders with different shapes.

Embodiment 3

[0034] The first step is to accurately weigh three parts of Bi(NO 3 ) 3 ·5H 2 O was added to 25mL of deionized water, ethanol or dimethylformamide solvent respectively, and stirred for 10 minutes until uniform, and three parts of bismuth-containing mixed solutions were obtained, respectively numbered A, B, and C;

[0035] In the second step, add 15 mmol of 1-butyl-3-methylimidazole chloride to A, B, and C respectively, stir for 10 minutes and mix well to obtain a white mixed solution;

[0036] In the third step, put the three white mixtures obtained in the second step into a KQ-100 ultrasonic cleaner for 30 min, and adjust the reaction temperature to 25°C;

[0037] In the fourth step, the three mixed solutions were centrifuged after ultrasonication, and the obtained precipitates were alternately washed three times with deionized water and ethanol, and then vacuum-dried at 60° C. for 24 hours to obtain BiOCl photocatalyst powders with different shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com