Preparation method of cobalt nickel sulfide/foam nickel super capacitor electrode

A supercapacitor, cobalt-nickel sulfide technology, used in hybrid capacitor electrodes, hybrid/electrical double-layer capacitor manufacturing, etc., to achieve the effects of high specific surface area, good rate performance, and high-efficiency electron transport channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Dissolve 1 mmol of cobalt nitrate, 0.5 mmol of nickel nitrate, 0.25 mmol of thiourea, 0.25 mmol of ammonium fluoride, and 25 mg of polyvinylpyrrolidone in 30 mL of deionized water under magnetic stirring to form a homogeneous mixed solution, and then transfer the homogeneous mixed solution to a hydrothermal In the reactor, at the same time, the nickel foam substrate (10mm×10mm×1mm) was etched with a nitric acid solution with a molar concentration of 0.1mol / L for 5 minutes, washed and dried, then immersed in the reaction solution in the hydrothermal reactor, at 100°C After hydrothermal reaction for 5 hours, ultrathin sheets were grown and deposited on the nickel foam substrate to assemble a honeycomb hierarchical structure of cobalt nickel sulfide to form an active electrode. The prepared active electrode was used as the working electrode, the platinum sheet was used as the auxiliary electrode, and the HgO / Hg electrode was used as the reference electrode, immersed in 2mol...

Embodiment 2

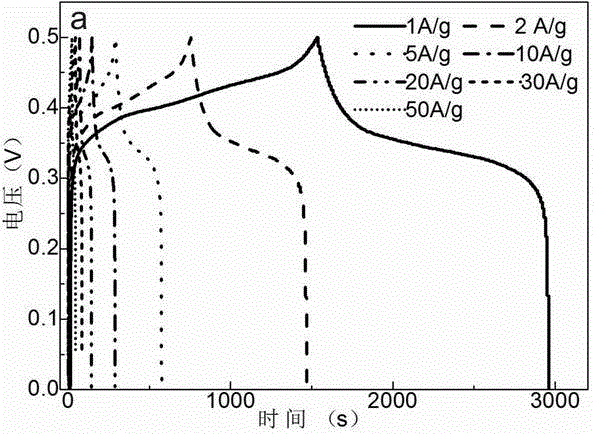

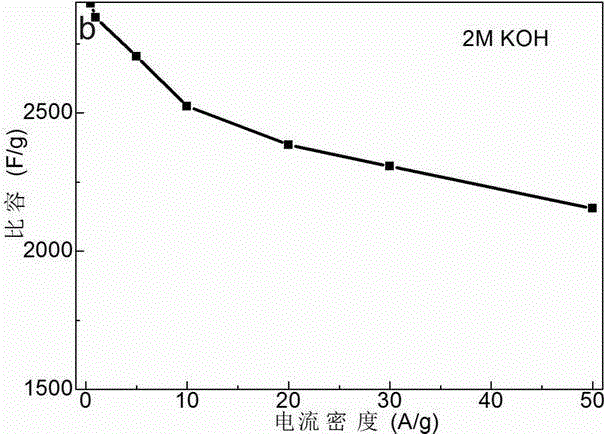

[0016] Dissolve 0.75 mmol of cobalt nitrate, 0.75 mmol of nickel nitrate, 0.5 mmol of thiourea, 0.5 mmol of ammonium fluoride and 50 mg of polyvinylpyrrolidone in 30 mL of deionized water under magnetic stirring to form a homogeneous mixed solution, and then transfer the homogeneous mixed solution to water In the thermal reaction kettle, at the same time, the foamed nickel substrate (10mm×10mm×1mm) was etched with a nitric acid solution with a molar concentration of 0.1mol / L for 5min, washed and dried, then immersed in the reaction solution in the hydrothermal reaction kettle, at 130 ℃ hydrothermal reaction for 2 hours, and then grow and deposit ultra-thin sheets on the nickel foam substrate to assemble a honeycomb multi-level structure cobalt nickel sulfide to form an active electrode. The prepared active electrode was used as the working electrode, and the three-electrode system was assembled according to Example 1 to test the electrochemical performance. The specific capacit...

Embodiment 3

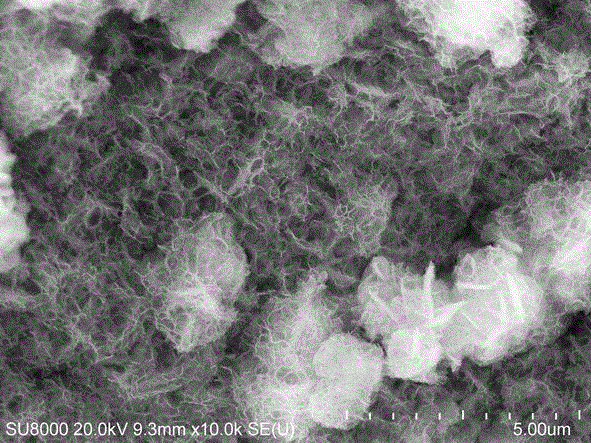

[0018] Dissolve 0.5 mmol of cobalt nitrate, 1 mmol of nickel nitrate, 0.5 mmol of thiourea, 0.25 mmol of ammonium fluoride, and 25 mg of polyvinylpyrrolidone in 30 mL of deionized water under magnetic stirring to form a homogeneous mixed solution, and then transfer the homogeneous mixed solution to a hydrothermal In the reaction kettle, at the same time, the nickel foam substrate (10mm×10mm×1mm) was etched with a nitric acid solution with a molar concentration of 0.1mol / L for 5 minutes, washed and dried, then immersed in the reaction solution in the hydrothermal reaction kettle, at 150°C Hydrothermal reaction for 5 hours, growth and deposition of ultra-thin lamellar honeycomb hierarchical cobalt nickel sulfide on the foamed nickel substrate (such as figure 1 shown) to form an active electrode. This type of electrode material has abundant pores, which is suitable for the rapid diffusion of electrolyte and is conducive to obtaining higher rate performance. The prepared electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com